Non-nail clamped electric heating floor system and electric heating floors thereof

A technology of electric heating floor and electric heating plate, which is applied in the field of building decoration, and can solve problems such as hidden safety hazards, cracking, and affecting heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (Example 1, electric heating floor)

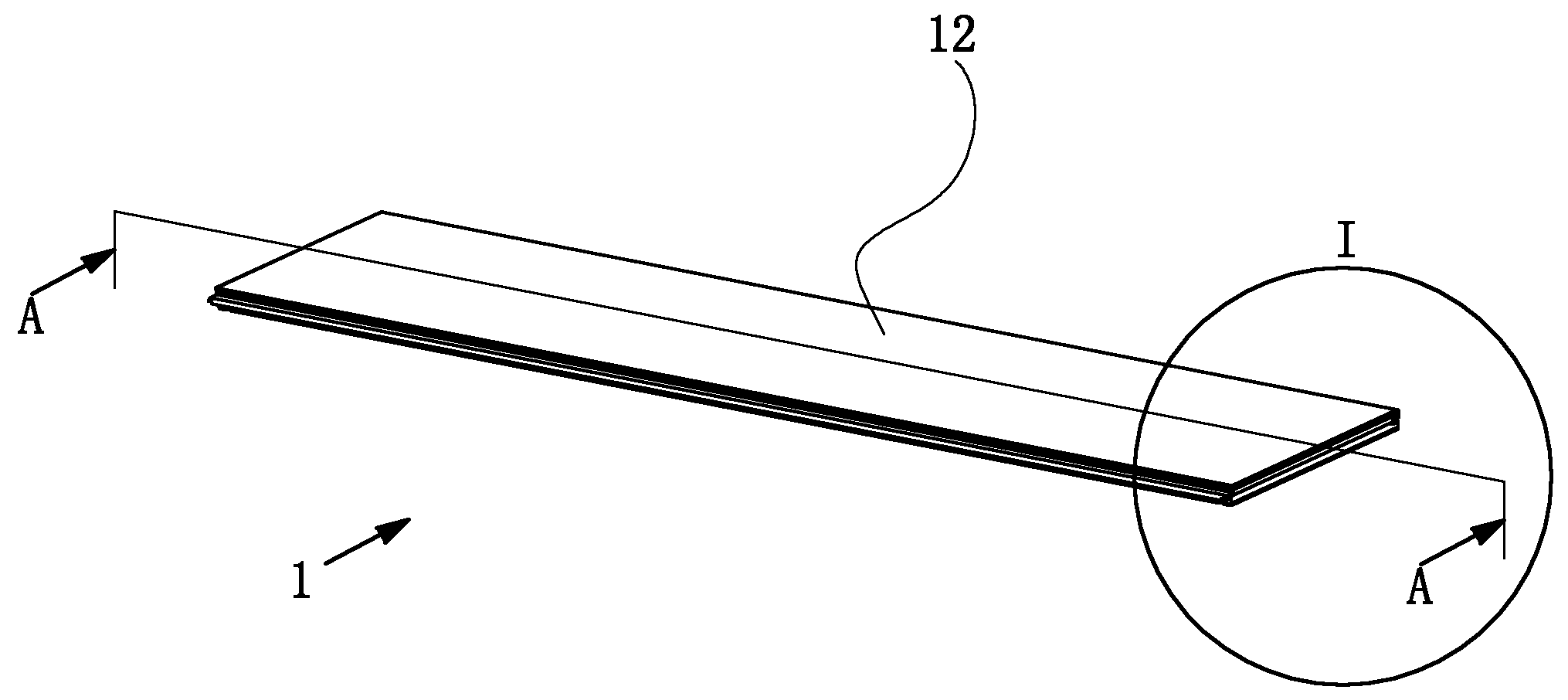

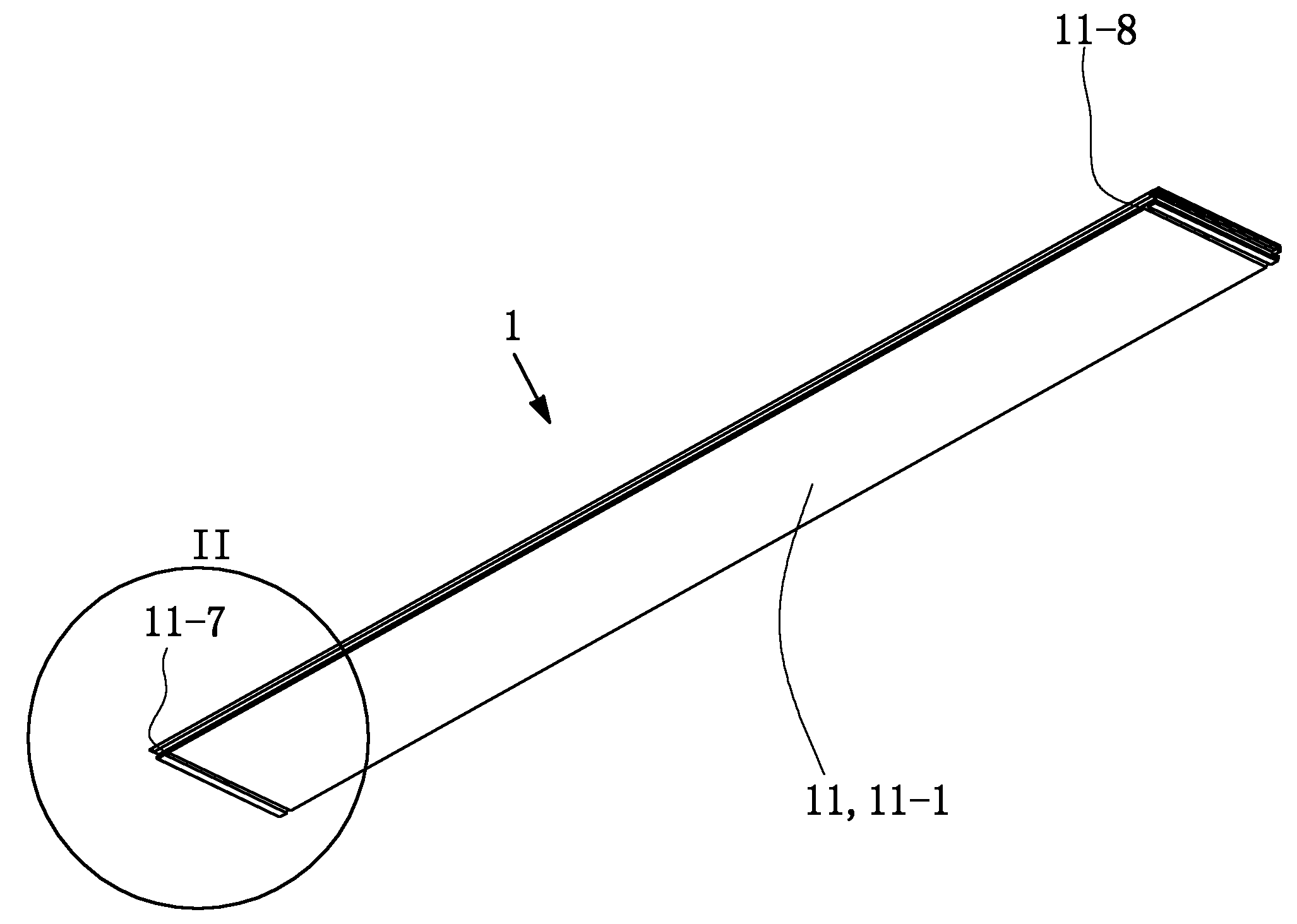

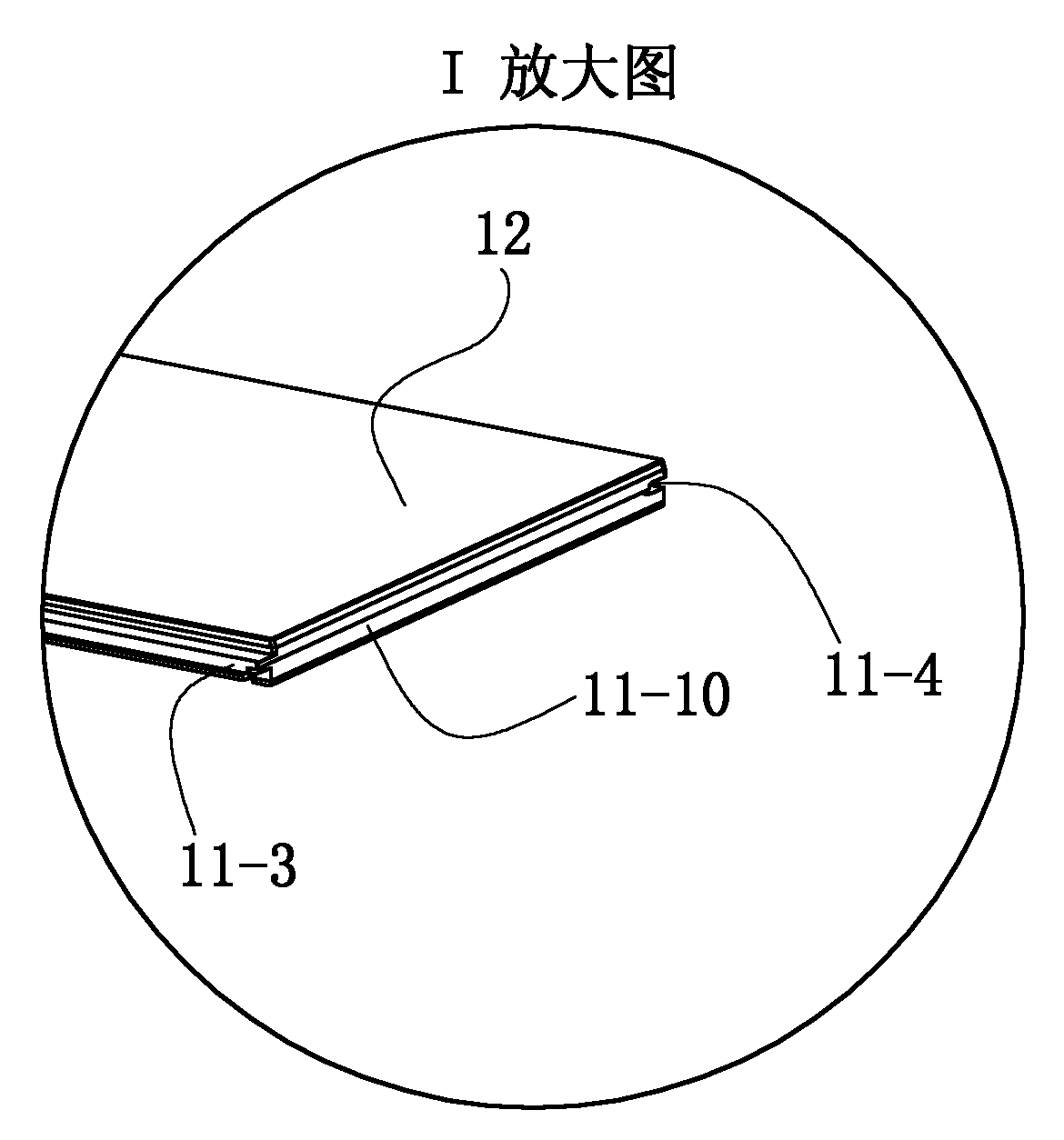

[0067] See Figure 8 and Figure 9 , The electric heating floor 1 of this embodiment includes a lower body 11 , an upper panel 12 , a carbon crystal electric heating plate 13 and a socket assembly 14 .

[0068] See figure 2 , Figure 4 and Figure 5 , the lower main body 11 is a homogeneous piece of wood, including a main body 11-1 with a basic shape of a cuboid, a tenon 11-3 located on the front side of the main body 11-1 and a tenon located on the rear side of the main body 11-1. The socket slot 11-4 and the socket tenon 11-3 are the parts for connecting and cooperating with the socket slots of the electric heating floor adjacent to the front side during use, and the socket slot 11-4 is the electric heating floor adjacent to the rear side during use. The joints and tenons of the floor are connected with each other.

[0069] The lower body 11 is also provided with a heating plate groove 11-2, a socket hole 11-5 at the left e...

Embodiment 2

[0075] (Embodiment 2, electric heating floor system installed without nails)

[0076] See Figure 10 , Figure 12 , Figure 13 , Figure 17 and Figure 22 In this embodiment, when describing the electric heating floor system without nails, the front and rear, left and right, and up and down directions are the same as those described in Embodiment 1, that is, the Figure 10 The length direction of the middle mounting base 2 is the front-to-back direction, with Figure 13 The width direction of the middle power supply keel 3 is the front-to-back direction, that is, Figure 10 The lower left in the middle is the front side, the upper right is the rear side, and the Figure 12 The up, down, left, and right directions of are the described up, down, left, and right directions.

[0077] See Figure 22 to Figure 25 , The nail-free clamping electric heating floor system of this embodiment includes an electric heating floor, an installation seat 2 and a power supply keel 3 . Wh...

Embodiment 3)

[0097] The rest of this embodiment is the same as Embodiment 2, the difference is that this embodiment is described according to a larger room, that is, the length of the mounting base 2 is described as being smaller than the length of the room, so the mounting base 2 of this embodiment is described in In actual use, several mounting bases 2 need to be spliced end to end in order to form a mounting base group equal to the length of the room to be laid, that is, among the two adjacent mounting bases 2, if the mounting base located on the rear side 2 is the middle transverse positioning part 22, then the rear end of the mounting seat 2 on the front side is the corresponding plate end transverse clamping part 21, if the front end of the mounting seat 2 on the rear side is the plate end transverse clamping part 21 , then the rear end of the mounting base 2 on the front side is the corresponding middle transverse positioning portion 22, so that the mounting base group is equivalen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com