Adhesion preventive silicon capacitance sound transmitter chip and its making method

A condenser microphone, anti-adhesion technology, applied in the direction of electrostatic transducer microphones, sensors, electret electrostatic transducers, etc., can solve the problems of insufficient rigidity, poor frequency response, thin thickness, etc., and achieve guaranteed performance , good performance, avoid the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

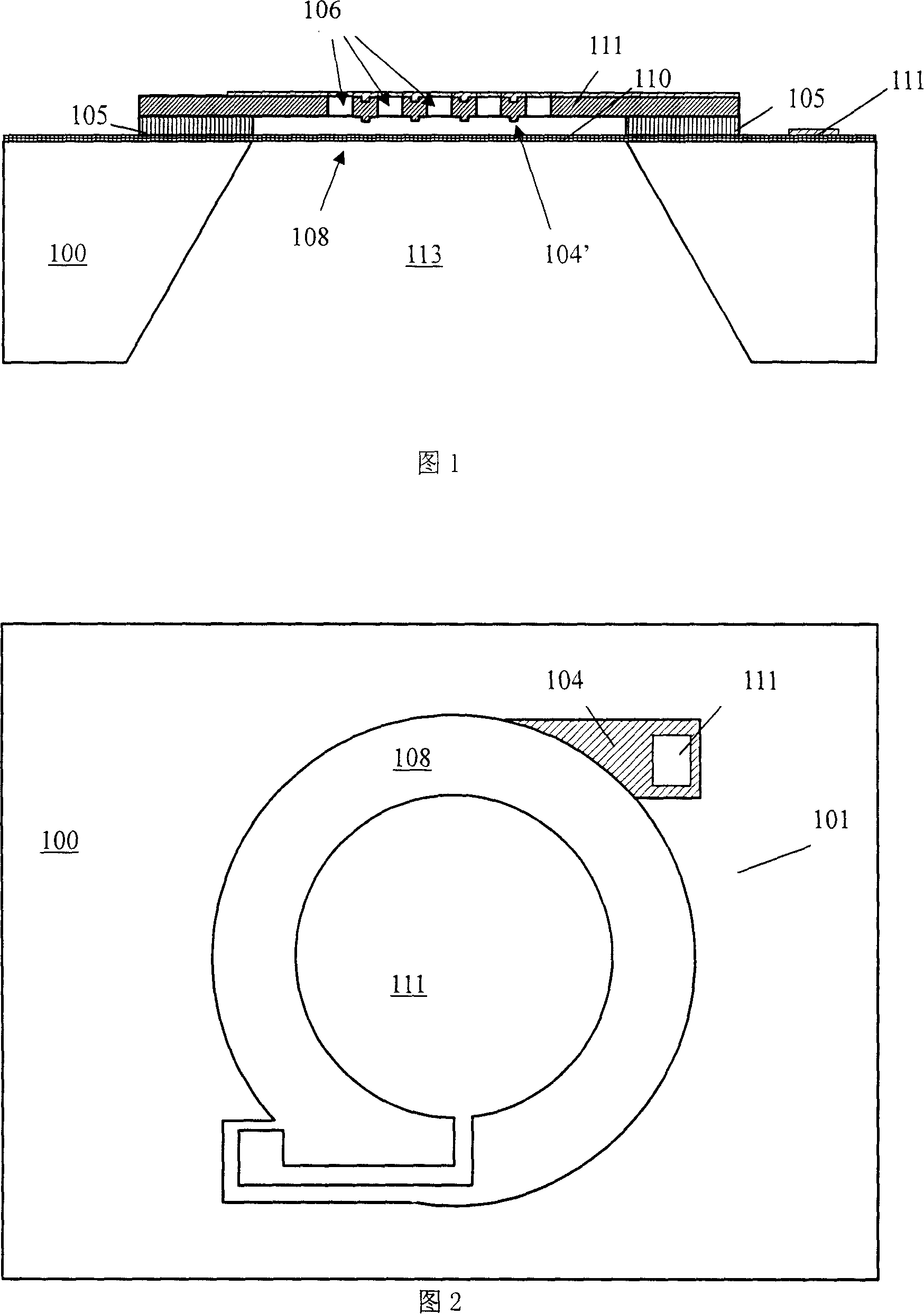

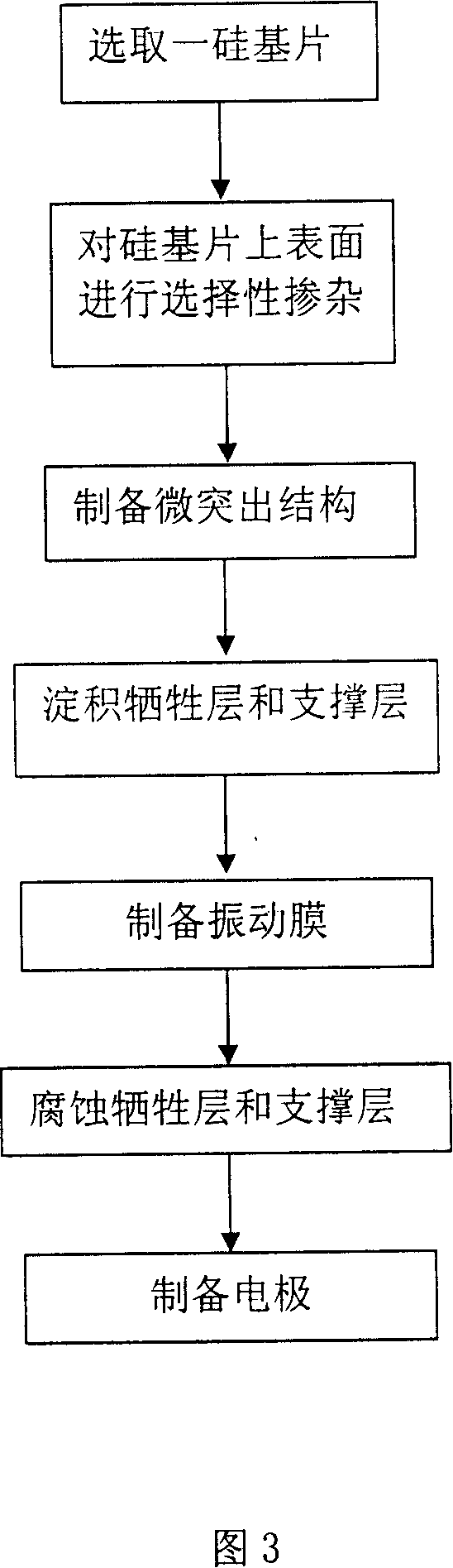

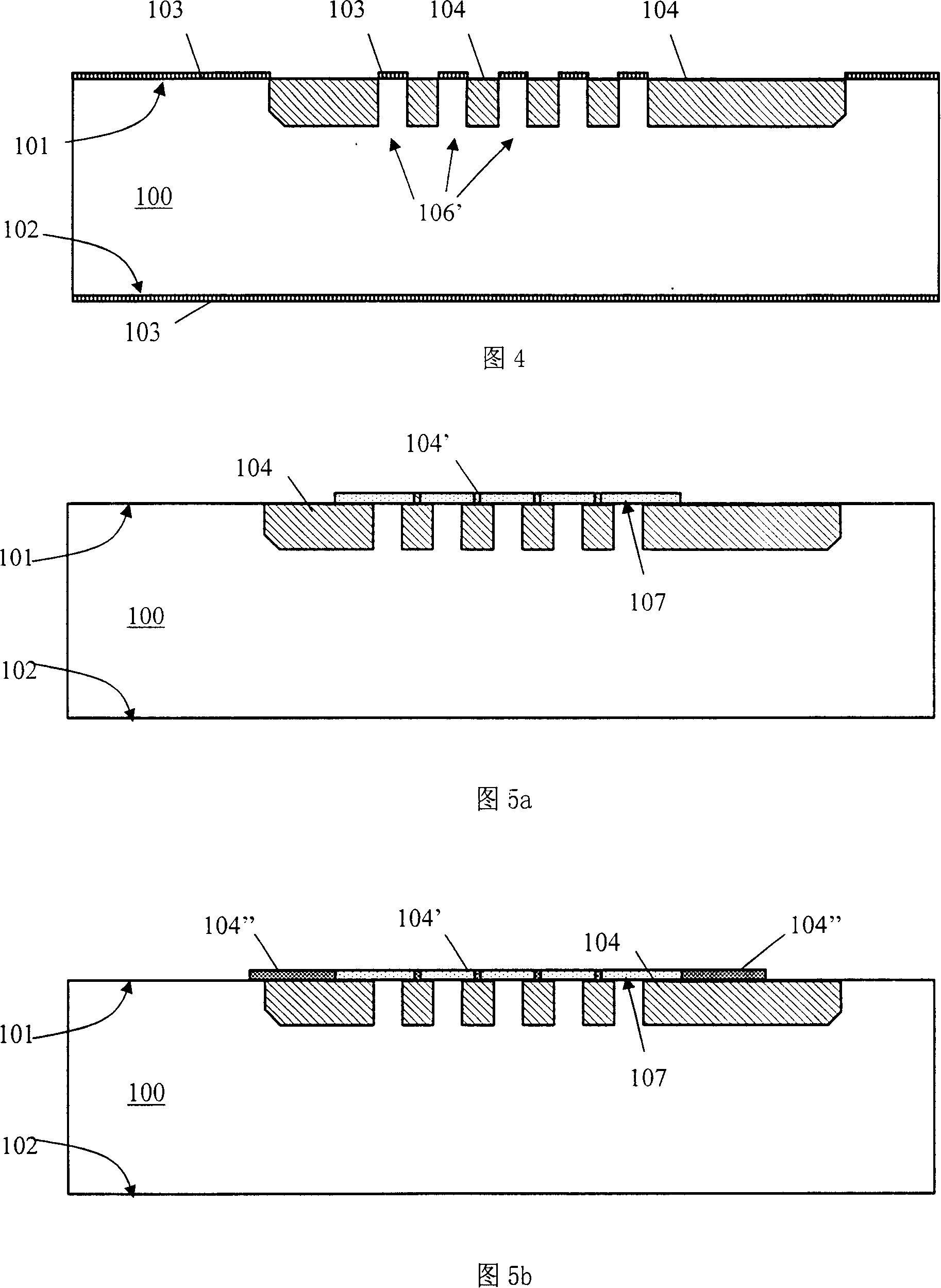

[0041] As shown in Figure 8a, the silicon microcapacitance microphone chip of the present embodiment comprises a silicon substrate 100, on the upper surface 101 of the silicon substrate 100, there is a perforated backplate formed by a doped layer 104, on the perforated backplate Acoustic grid holes 106 are distributed in an array; the upper surface of the doped layer 104 is prepared with an anti-adhesive raised structure 104 ′. There is an annular isolation support layer 105 above the perforated backplane formed by the doped layer 104, and a vibrating membrane 108 is arranged on the isolation supporting layer 105. Electrodes 111 are respectively provided on the surfaces of the vibrating membrane 108 and the doped layer 104, and on the vibrating membrane There is an air gap 110 between 108 and the perforated backplane, and the thickness of the air gap can be between 0.5 microns and 10 microns. The thickness of the isolation support layer 105 is greater than the thickness of the...

Embodiment 2

[0051] As shown in Figure 8a, the silicon microcapacitance microphone chip of the present embodiment comprises a silicon substrate 100, on the upper surface 101 of the silicon substrate 100, there is a perforated backplate formed by a doped layer 104, on the perforated backplate It has acoustic grid holes 106 distributed in an array; the upper surface of the doped layer 104 is prepared with an anti-adhesive raised structure 104', and an annular first isolation support layer 104", the thickness of the first isolation support layer 104" is the same as that of the protrusion Structure 104' is consistent. There is also an annular second isolation support layer 112 above the first isolation support layer 104 ", and the first isolation support layer 104 " and the second isolation support layer 112 constitute the isolation support layer 105; The membrane 108, the surface of the vibrating membrane 108 and the doped layer 104 are respectively provided with electrodes 111, and there is ...

Embodiment 3

[0056] As shown in Figure 8a, the silicon microcapacitance microphone chip of the present embodiment comprises a silicon substrate 100, on the upper surface 101 of the silicon substrate 100, there is a perforated backplate formed by a doped layer 104, on the perforated backplate It has acoustic grid holes 106 distributed in an array; the upper surface of the doped layer 104 is prepared with an anti-adhesive raised structure 104', and the cross-sectional shape of the raised structure 104' can be circular, rectangular, polygonal, etc., and a single raised structure The cross-sectional area of can be between 20 square micrometers and 1000 square micrometers. An exemplary circular protruding structure with a cross-sectional radius of 5 micrometers can be selected, and the thickness of the protruding structure is 0.1 micrometers.

[0057] There is an annular isolation support layer 105 above the perforated backplane formed by the doped layer 104, and a vibrating membrane 108 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com