Method for manufacturing high-chromium alloy overlaying composite abrasion resistant plate

A high-chromium alloy and manufacturing method technology, applied in the field of wear-resistant plates, can solve the problems of increased cost and small profit, and achieve the effects of cost reduction, high profit and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

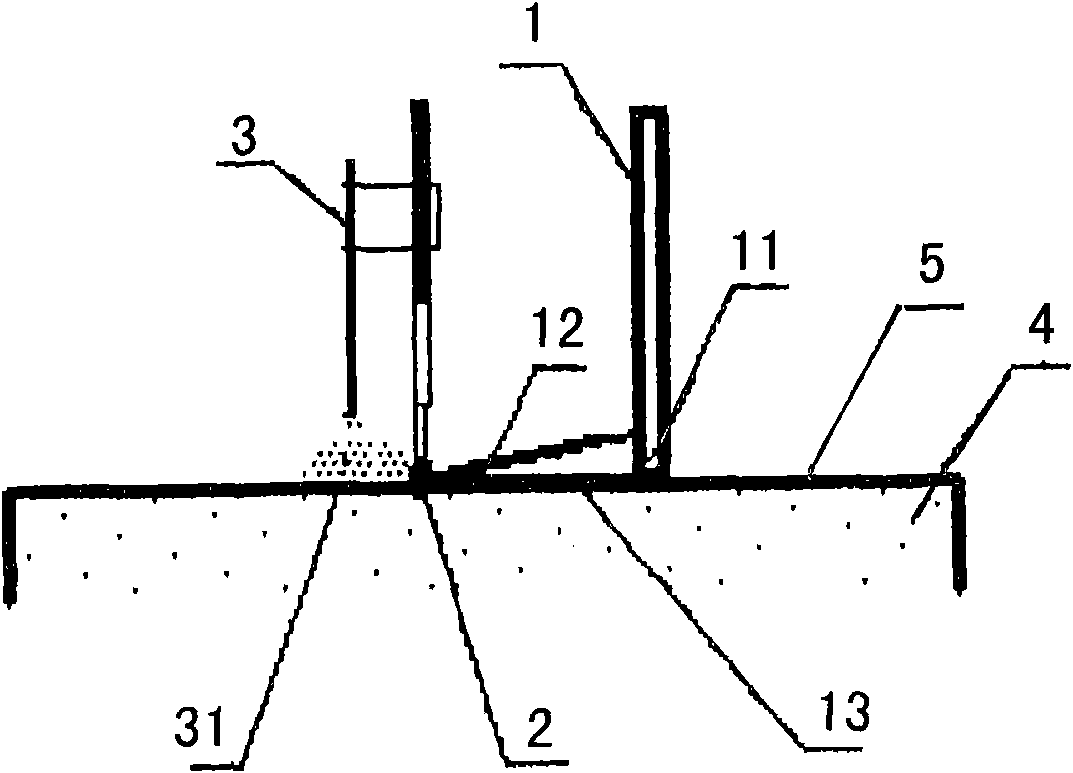

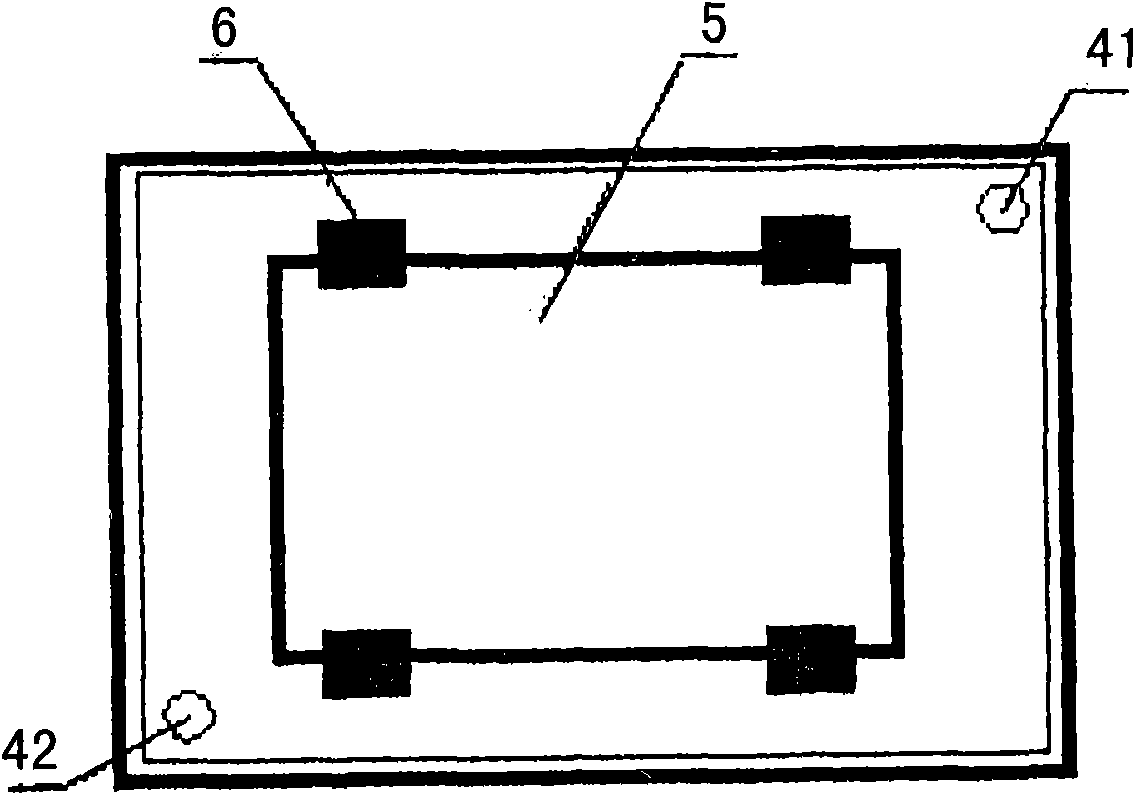

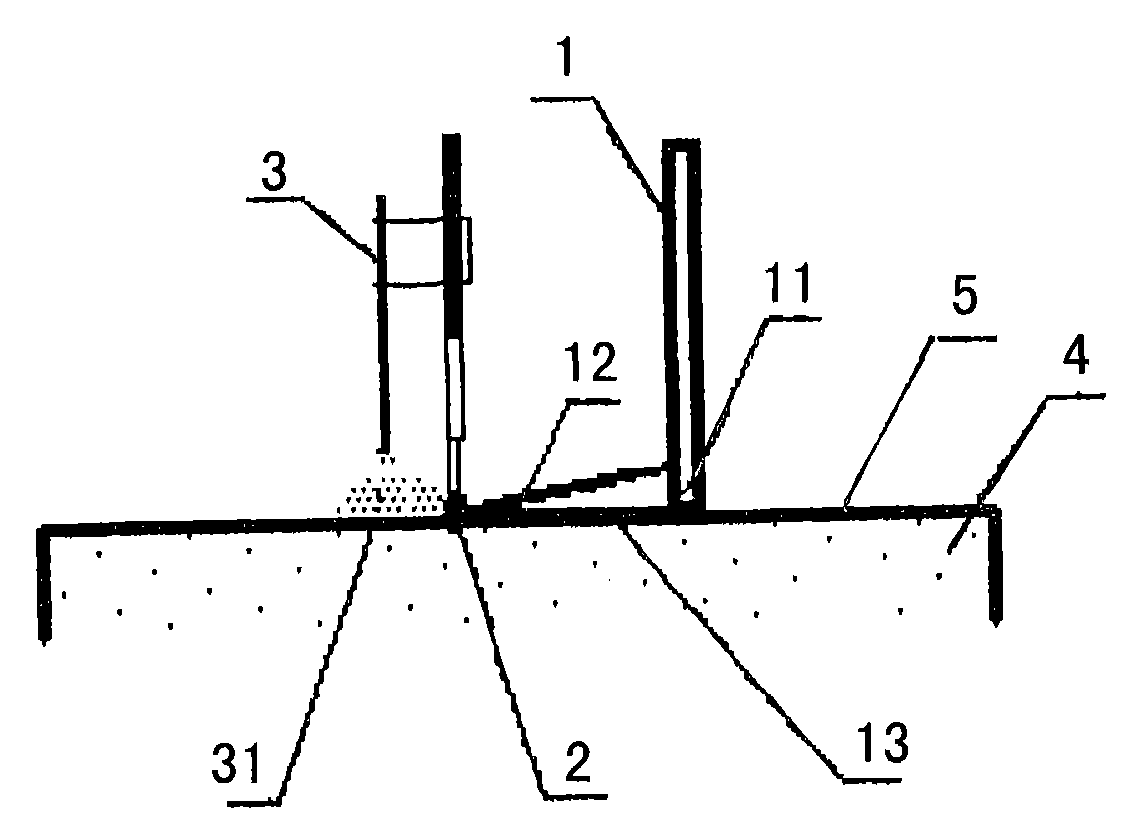

[0030] The manufacturing method of the high-chromium alloy surfacing composite wear-resistant plate of the present invention, and the equipment for manufacturing the surfacing composite wear-resistant plate using this method are shown in FIG. 1 . A powder lowering device 1 is added in front of the self-shielding flux-cored welding wire 2 contact tip, and a spray cooling device 3 is installed behind it. The wear-resistant matrix plate 5 is pressed and fixed on the upper surface of the workbench 4 by the pressing plate 6 . The powder lowering pipe 11 of the powder lowering device 1 is perpendicular to the wear-resistant substrate plate 5 , and the lower end of the powder lower pipe 11 has a scraper 12 , and one side of the scraper 12 is in parallel contact with the upper surface of the wear-resistant substrate 5 . The spray cooling device 3 behind the self-shielding flux-cored wire 2 sprays cooling water 31 to the surface of the wear-resistant matrix plate 5 during operation.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com