Seeder with middle ditching, unit profile modeling and seeding depth adjusting functions

A seeder and single-unit technology, which can be used in sowing seeders, interval-type quantitative seeding machines, and excavation/covering of trenches, etc., can solve the problems of complex production process, high price, and single function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

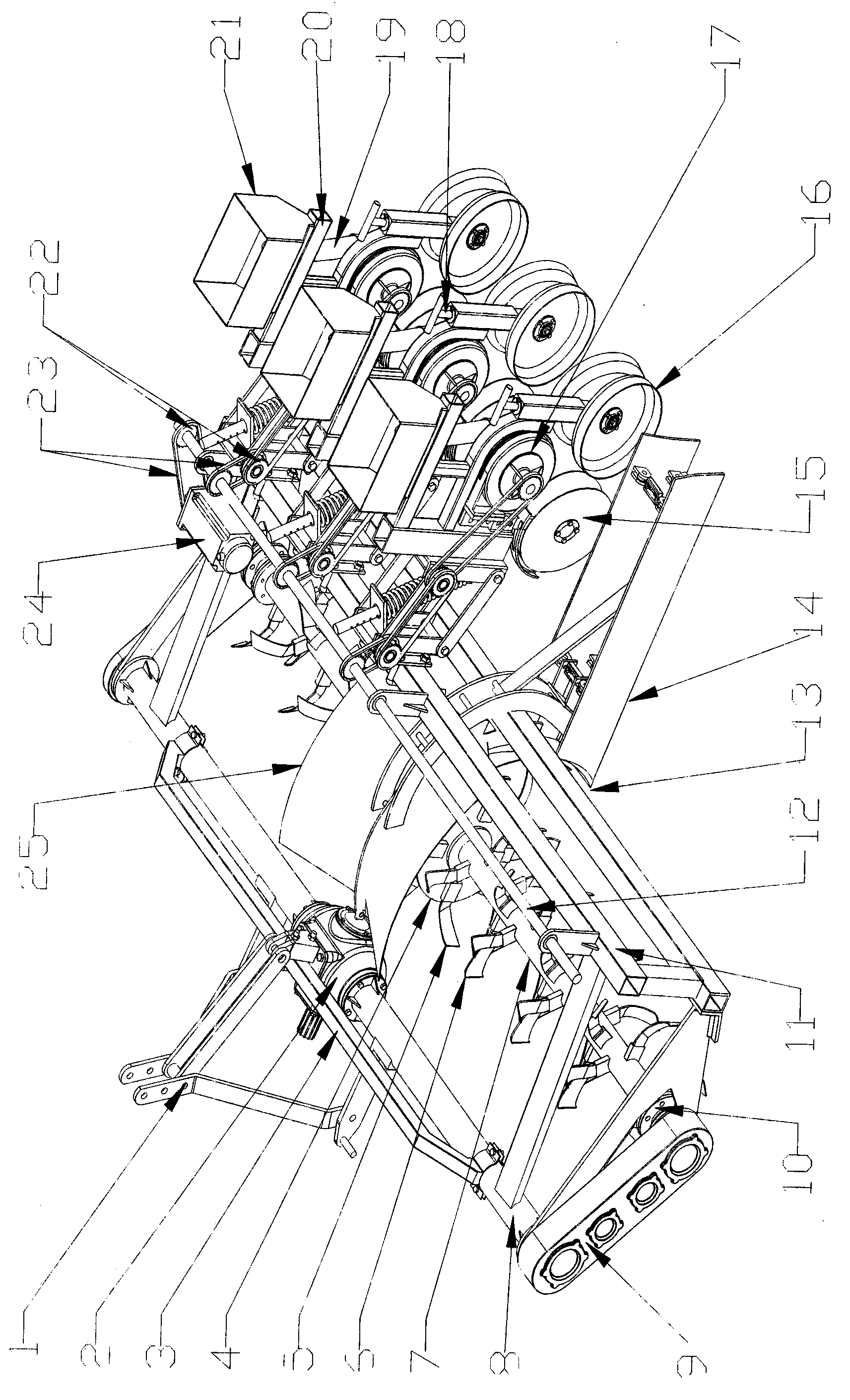

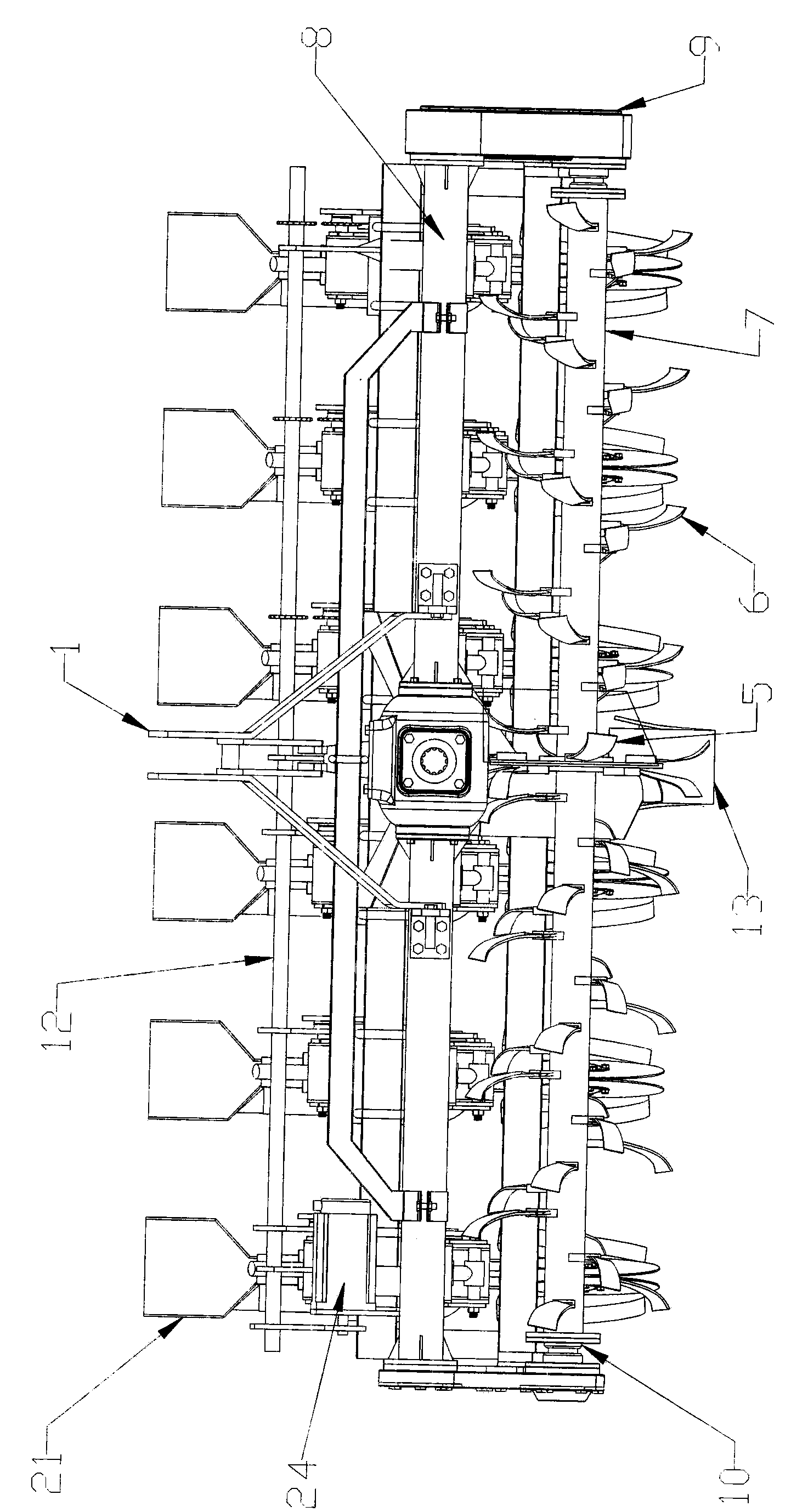

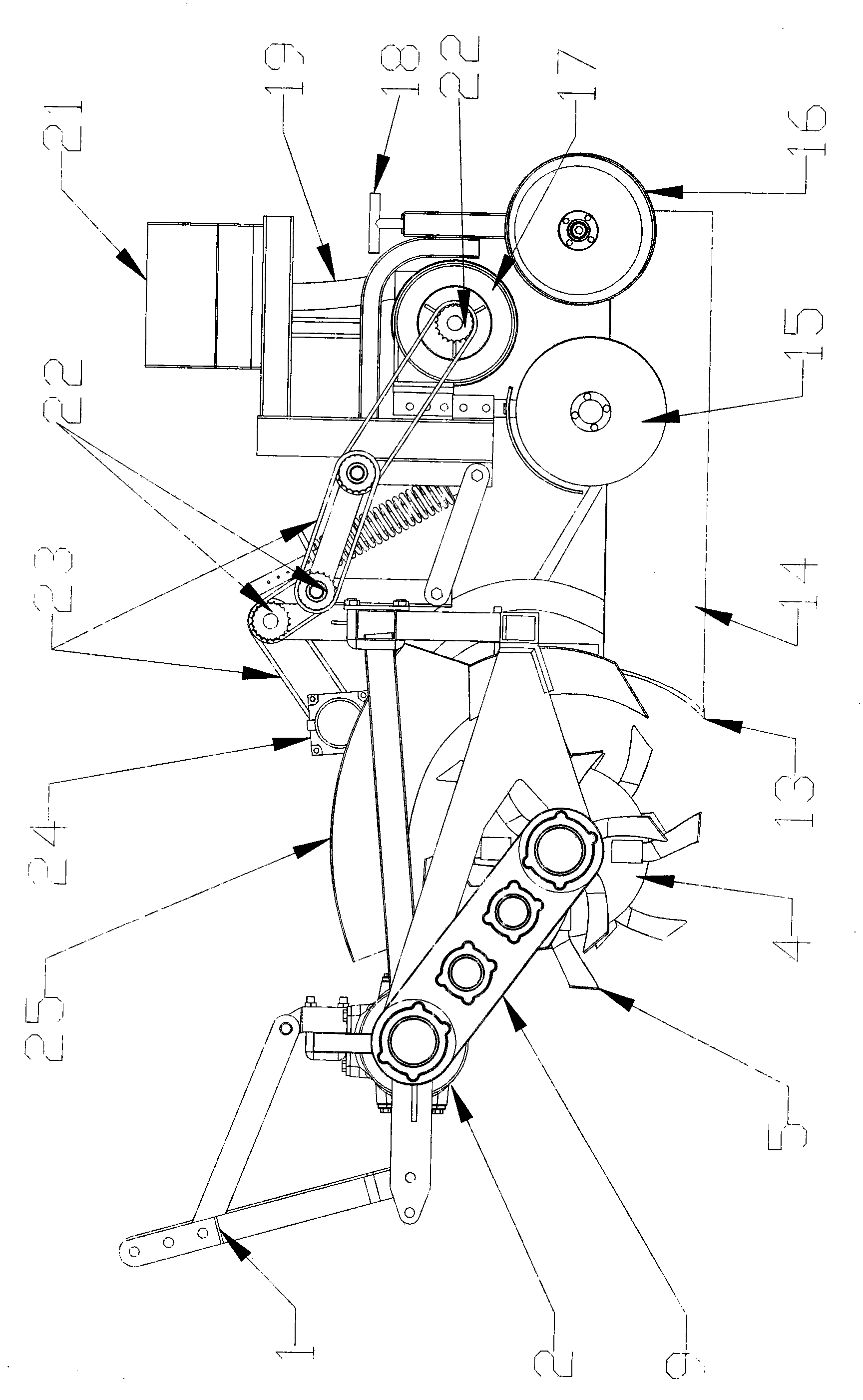

[0022] The machine works six rows at a time, and there are three rows on each side of the ditch in the middle, so that the view is clear and figure 1 The three sowing units on the left are omitted in the figure. When working, the tractor is connected with the implement through the suspension frame 1, the power output shaft of the tractor transmits the power to the gearbox 2 through the universal joint, the speed is changed through the gearbox 2, and then the power is transmitted to the side of the implement through the rotary tillage transmission shaft 8 The gear box 9, and then the power of the gear box is transmitted to the rotary tiller shaft 7 and the ditching cutter head 4 by the coupling 10, so that the rotary tiller machete 6 and the ditching machete 5 follow the rotary tiller shaft 7 and The ditching cutter head 4 rotates at high speed for rotary tillage and ditching operations, the soil retaining plate 25 can divide the soil thrown up by the ditching machete 5 to both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com