Bidirectional magnetic saturated time difference fluxgate sensor

A fluxgate sensor and time difference technology, which is applied to the magnetic field measurement, the size/direction of the magnetic field and other directions using the principle of magnetic flux control, which can solve the problems of complex data processing of the fluxgate sensor, unfavorable real-time detection, and complex detection circuits. , to make up for the harsh process requirements, reduce power consumption, and achieve the effect of simple detection circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

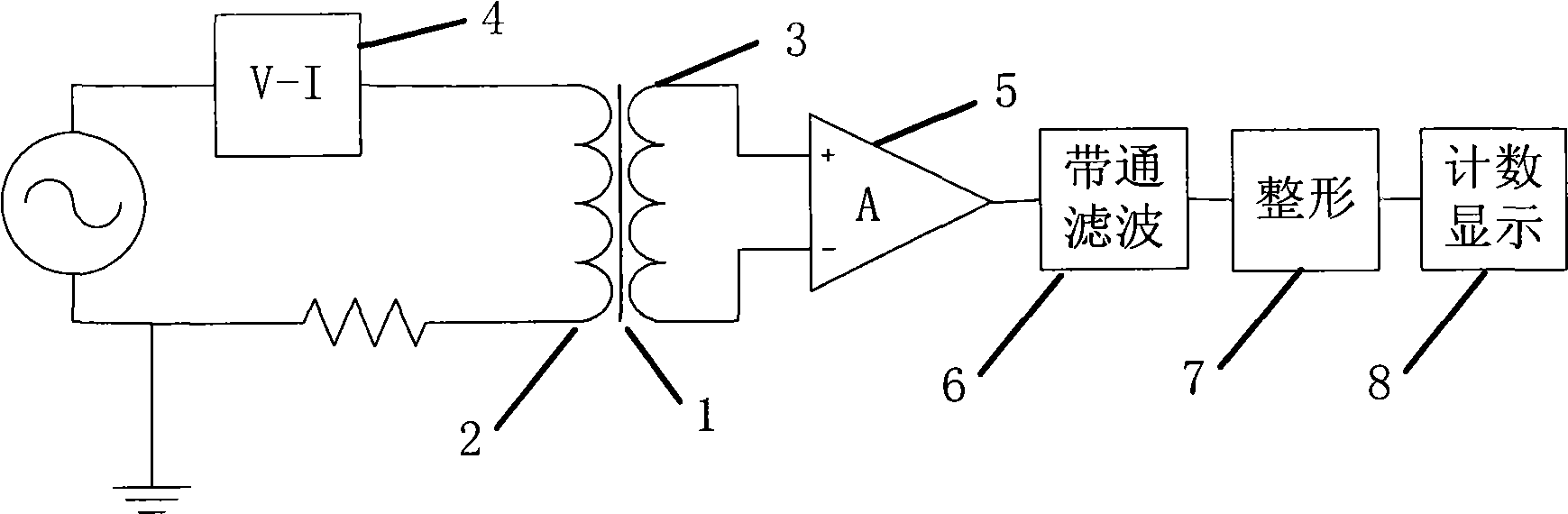

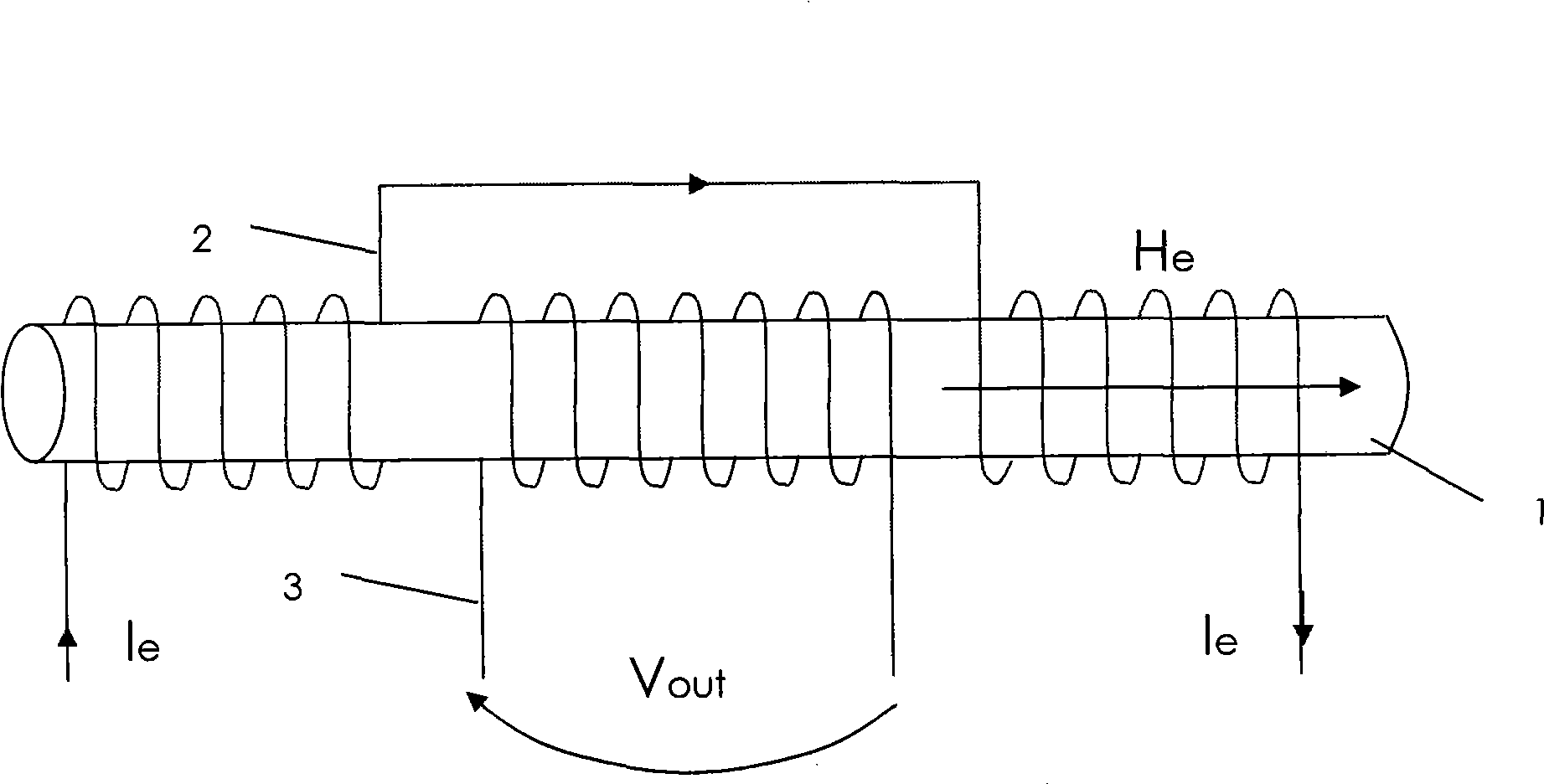

[0021] The sensor magnetic core 1 is made of nano-microcrystalline iron-based alloy to form a rod-shaped open magnetic circuit. The sensor magnetic core 1 is symmetrically pressed with a skeleton made of PCB base material, and the excitation circuit connected to the voltage-current conversion circuit 4 is alternately wound on it. The coil 2 and the induction coil 3 whose output pole is connected to the amplifier circuit 5, the output poles of the induction coil 3 are all connected to the amplifier circuit 5, and the amplifier circuit 5 is connected to the counting display circuit 8 through the band-pass filter circuit 6, the shaping circuit 7, and the period The voltage signal is converted into an excitation current by the voltage-to-current converter 4, and input to the excitation coil 2 on the sensor core 1 to generate a core excitation magnetic field, which periodically excites the sensor core 1, so that the sensor core 1 periodically reaches In the supersaturation state, wh...

Embodiment 2

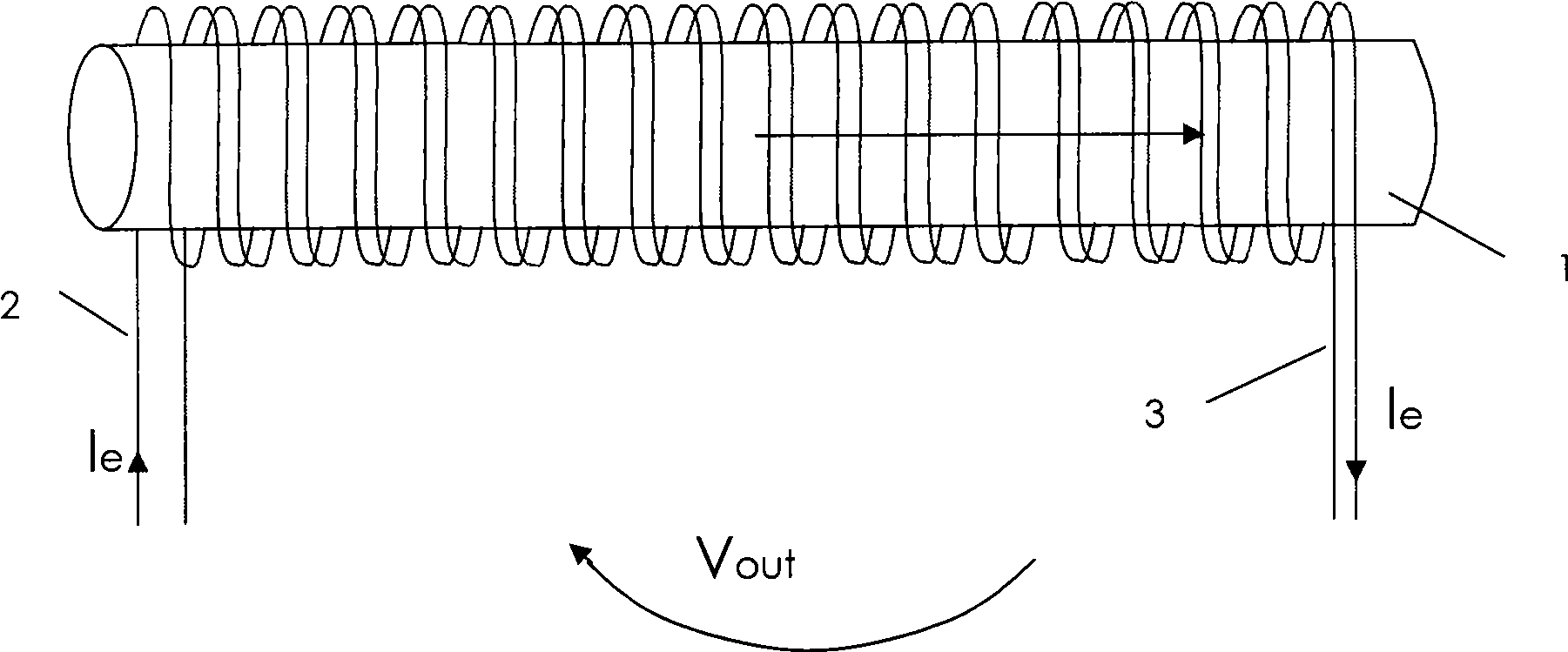

[0039] The sensor core 1 is made of iron-based amorphous alloy into a sheet structure, and the sensor core 1 is symmetrically pressed with a skeleton made of ABS plastic, and an excitation coil 2 connected to a voltage-current conversion circuit 4 is wound around the two ends of the sensor core 1. The middle section is wound with an induction coil 3, and the output poles of the induction coil 3 are connected to the amplifying circuit 5, and the amplifying circuit 5 is connected to the counting display circuit 8 through the band-pass filter circuit 6, the shaping circuit 7, and the periodic voltage signal is converted by the voltage-current converter 4 The excitation current is input to the excitation coil 2 on the sensor core 1 to generate the core excitation magnetic field, and the excitation magnetic field periodically excites the sensor core 1 to make the sensor core 1 periodically reach the supersaturation state. When the two-way magnetic saturation time difference When the...

Embodiment 3

[0042] The sensor magnetic core 1 is made of permalloy to make a closed magnetic circuit structure. The sensor magnetic core 1 is symmetrically pressed with a skeleton made of PVC material, and the two ends of the beam are wound with an excitation circuit connected to the voltage-current conversion circuit 4. The coil 2 is wound with an induction coil 3 in the middle, and the output poles of the induction coil 3 are connected to the amplifying circuit 5, and the amplifying circuit 5 is connected to the counting display circuit 8 through the band-pass filter circuit 6, the shaping circuit 7, and the periodic voltage signal is converted by voltage and current The device 4 converts the excitation current into the excitation coil 2 on the sensor core 1 to generate a magnetic core excitation magnetic field, and the excitation magnetic field periodically excites the sensor core 1 to make the sensor core 1 periodically reach an oversaturation state. When the two-way When there is a we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com