Workpiece conveying system applied to automobile welding line

A conveying system and welding line technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve the problem of low utilization rate of conveying line equipment, achieve high production efficiency, low comprehensive investment cost, and ensure start-up rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The specific implementation of the continuous and uninterrupted transportation scheme of two fixture trolleys for a single A model is as follows:

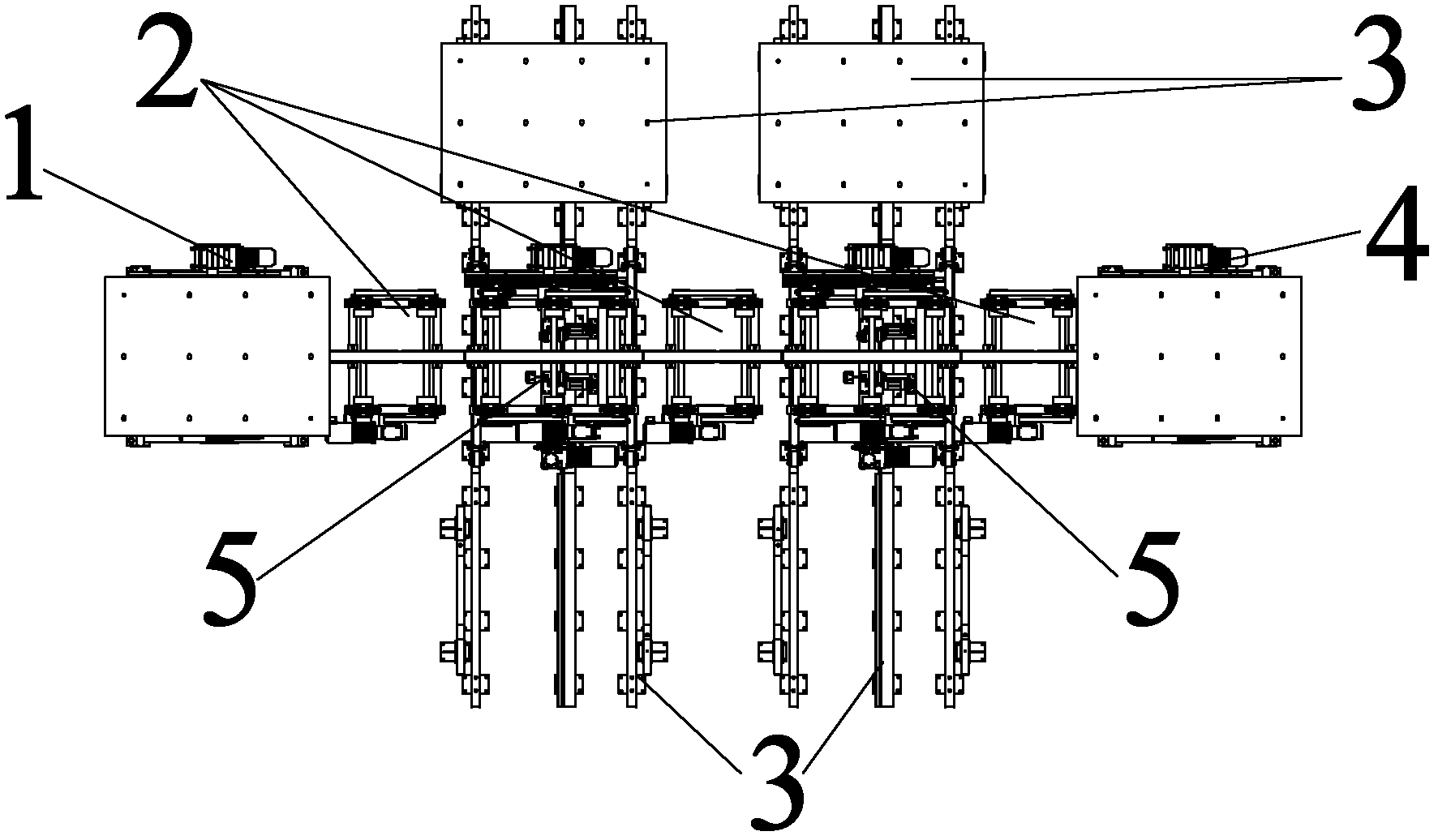

[0030] like Figure 4 As shown, there are two fixture trolleys A1 and fixture trolley A2, two fixture trolley switching devices 5, three corresponding transition devices 2, and four fixture trolley storage devices 3. When the fixture trolley A2 at the welding station performs welding operations, the fixture trolley A1 at the loading station can perform loading operations while the fixture trolley A2 is welding.

[0031]When the loading operation of the fixture trolley A1 is manually completed in the loading station, if the welding of the fixture table and fixture trolley A2 at the welding station has not been completed, then the lifting and rolling bed of the loading station will put the fixture trolley A1 Lifting, the jig trolley A1 breaks away from the jig fixing mechanism of the loading device 1, and then the jig trolley...

Embodiment 2

[0035] The switching of the respective fixture trolleys of the two different models A and B is implemented as follows:

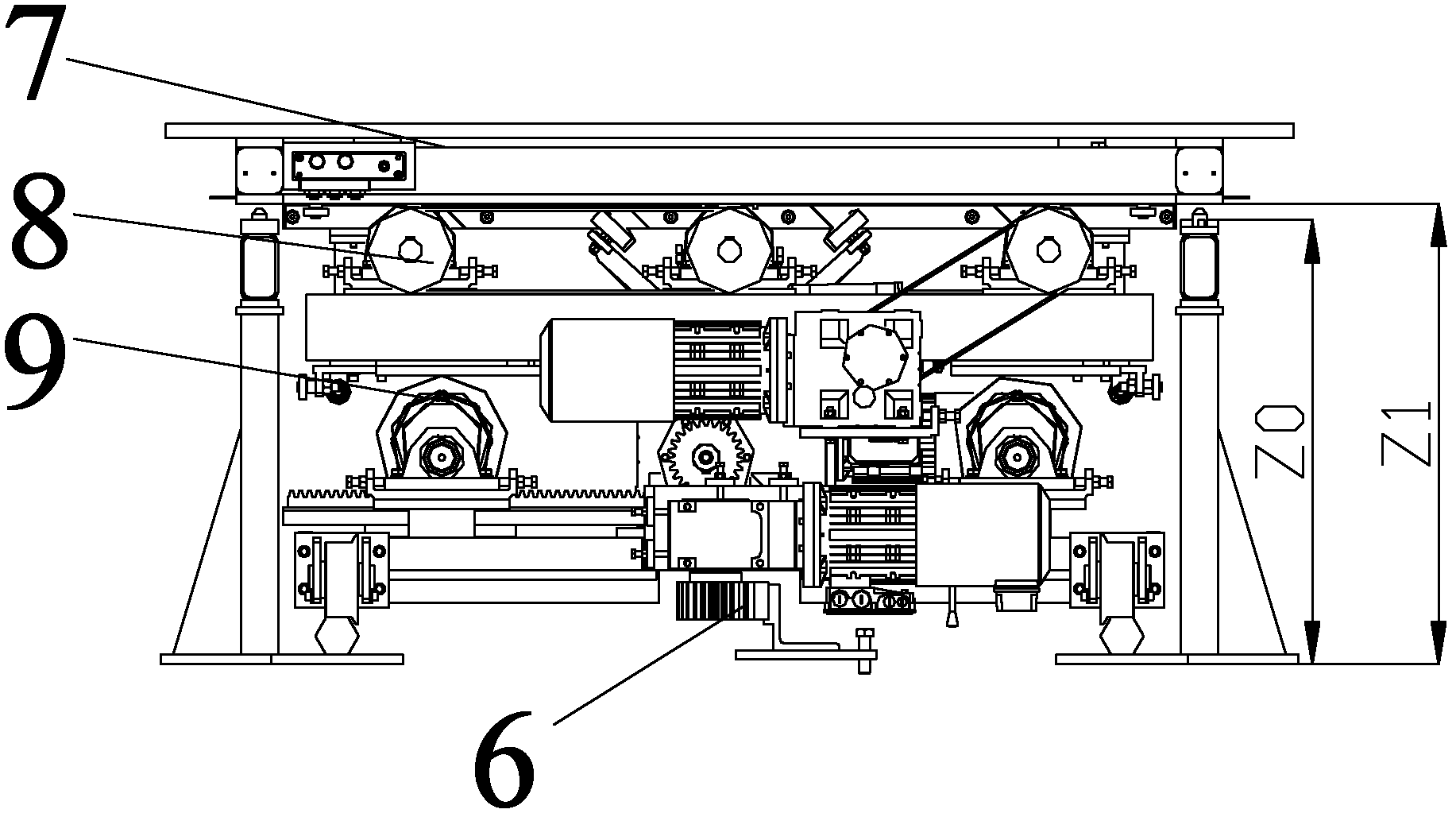

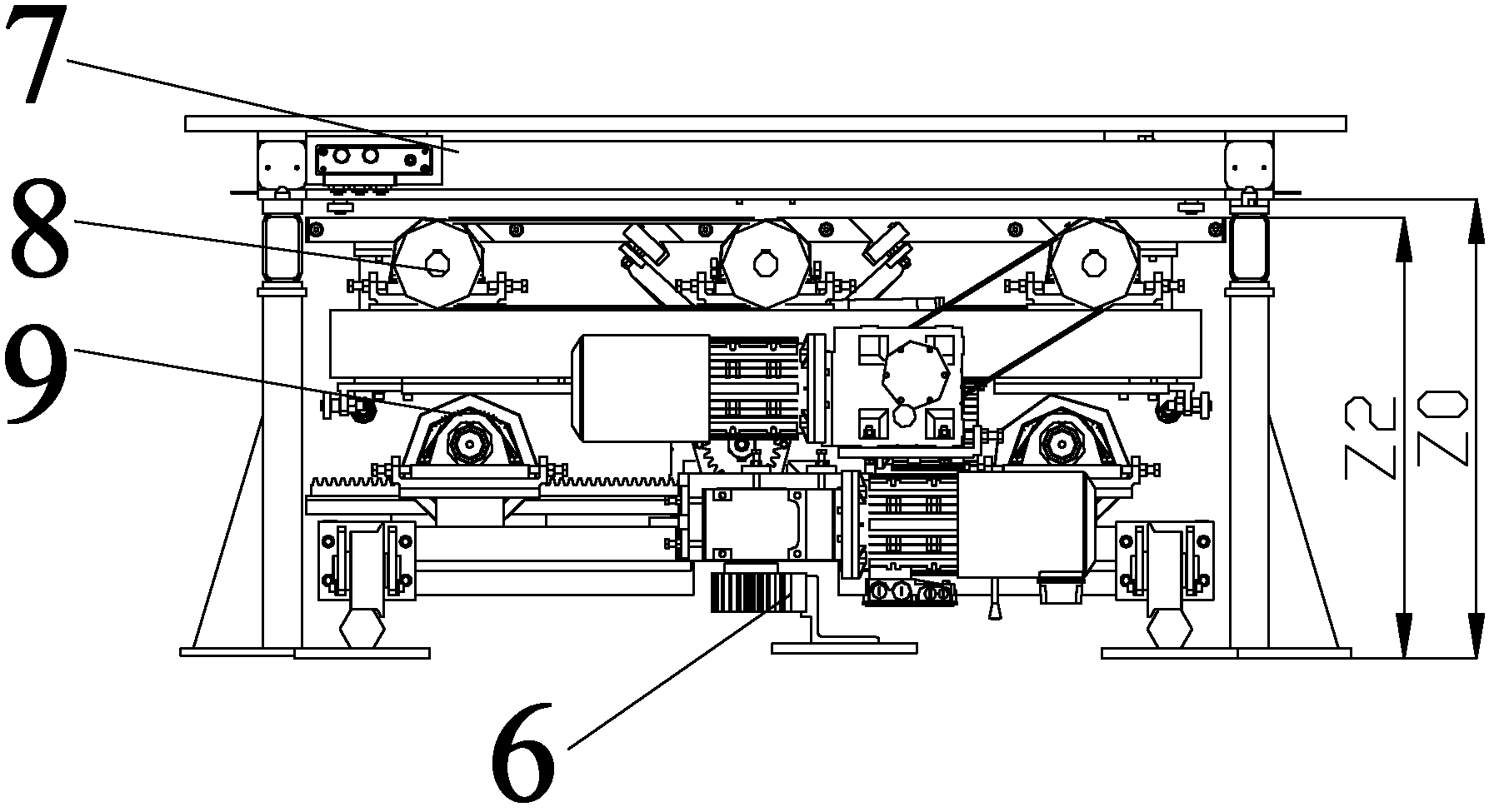

[0036] like Figure 5 to Figure 8 As shown, on this workpiece conveying system, there are fixture trolley A1 and fixture trolley A2 belonging to model A, and fixture trolley B1 and fixture trolley B2 belonging to model B. According to the production task preparation, the fixture trolley switching device 5 The jig trolley storage device 3 on both sides, the jig trolley storage device 3 on one side is used to store the jig trolley of the A model, and the jig trolley storage device 3 on the other side is used to store the jig trolley of the B model. After the welding and assembly production of model A is completed, it is necessary to switch to the secondary assembly production of model B. like Figure 6 , at this time, the fixture trolley A2 completes the welding transfer and returns to the fixture trolley storage device 3 of the model A, and the fixture trol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com