Degradable bio-compatible water treatment filler and preparation method thereof

An affinity, water treatment technology, applied in water treatment and other sewage treatment fields, can solve the problem of increased treatment cost, shorten the film hanging time, enhance the removal efficiency, and improve the effect of water treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

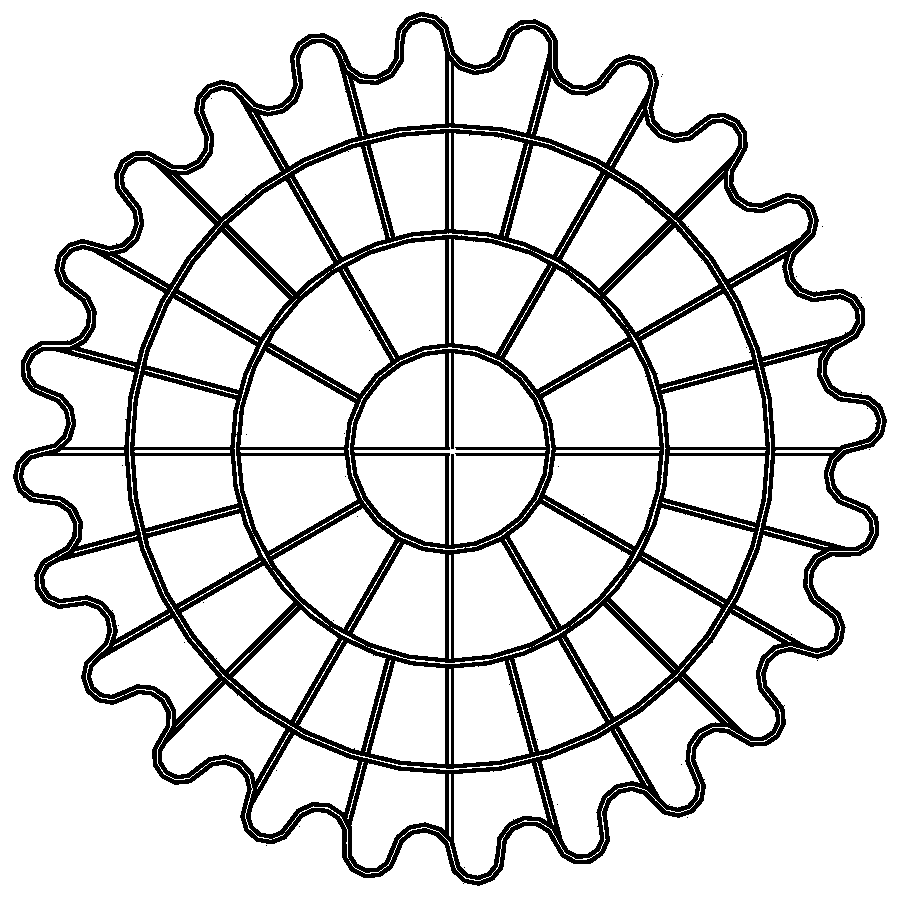

[0033] Take 70kg of polybutylene succinate with a fineness above 200 mesh, 14.5kg of light calcium carbonate, 22.5kg of starch, 2.5kg of activated carbon, 0.88kg of nutrient salt (0.81kg of ferrous chloride, 0.06kg of magnesium chloride), 0.55kg of silane coupling agent, 1.75kg of polyvinyl alcohol, 1.75kg of stearic acid, and 1kg of white oil are placed in a mixer and mixed evenly, and sent to a granulator for high-temperature processing into granules. Then take 90kg of the prepared masterbatch and 30kg of foaming agent and mix them into the extruder barrel. What is extruded from the die mouth of the machine head is a gray-black cylinder with a cross support frame and a tooth-shaped cross-section inside. After sizing, cooling and molding, cutting and shaping, the product 1 of the moving bed A-type filter material can be obtained, such as figure 1 As shown, its density is 0.98kg / L.

Embodiment 2

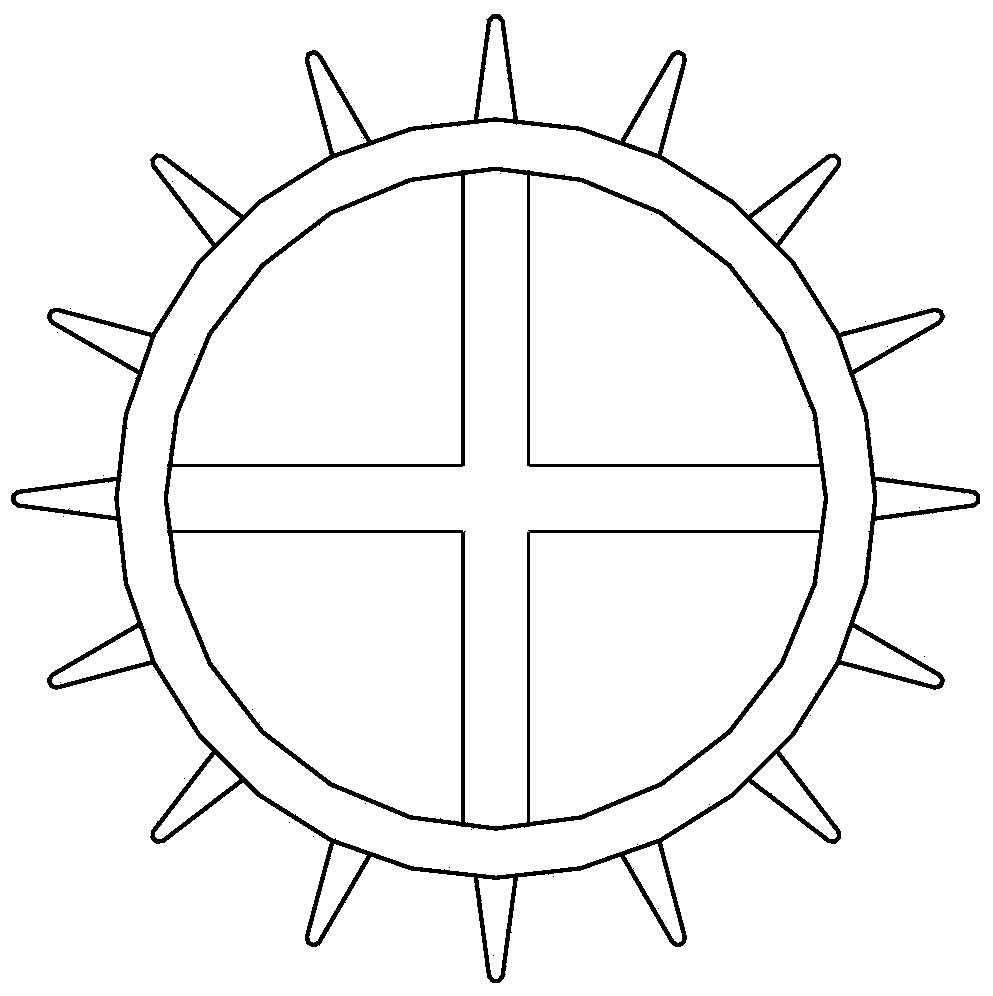

[0035] Take 55kg of polyε-caprolactone with a fineness above 200 mesh, 16.8kg of light calcium carbonate, 0.75kg of cellulose, 16.8kg of starch, 2.25kg of zeolite powder, 0.75kg of nutrient salt (0.65kg of ferrous sulfate, 0.65kg of magnesium sulfate 0.11kg), 0.75kg of silane coupling agent, 1.5kg of polyvinyl alcohol, 1.5kg of stearic acid, 3.75kg of calcium chloride, and 0.8kg of white oil are mixed in a mixer and sent to a granulator for high temperature processing into granules . Then take 70kg of the prepared masterbatch and 10kg of foaming agent and mix them into the extruder barrel. What is extruded from the die mouth of the machine head is a gray-black rosette cylinder, which is sized, cooled and shaped, cut and shaped. The product 2 of moving bed filter material B type can be obtained, such as figure 2 As shown, its density is 0.97kg / L.

Embodiment 3

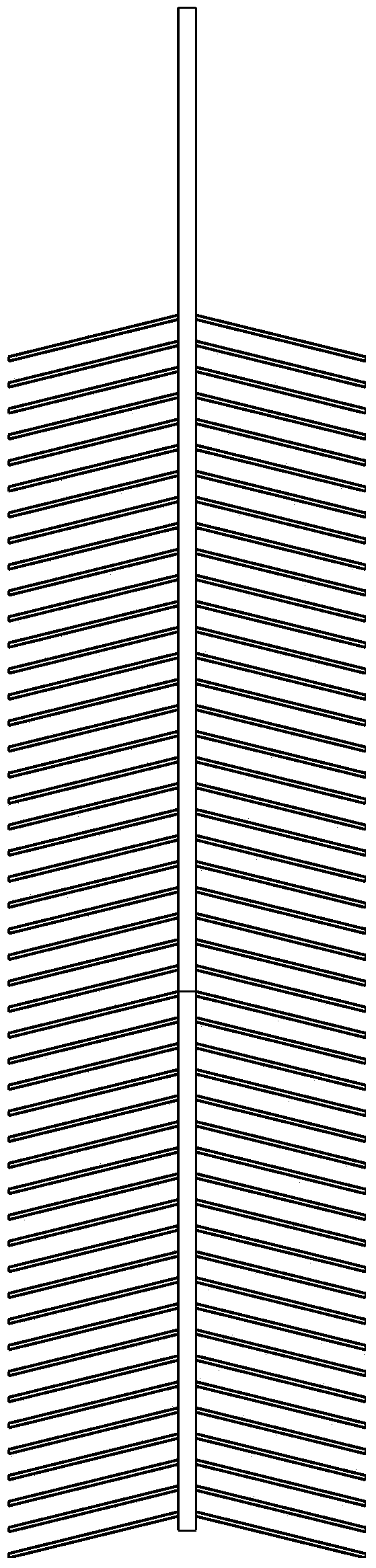

[0037] Take 60kg of polybutylene succinate with a fineness above 200 mesh, 12.5kg of hydroxyapatite, 0.5kg of molasses, 20.5kg of starch, 5.5kg of activated carbon, 0.65kg of nutrient salt (0.611kg of ferrous chloride, sulfuric acid Magnesium 0.039kg), silane coupling agent 0.65kg, polyvinyl alcohol 1.2kg, stearic acid 1.2kg, calcium chloride 1.5kg, white oil 1.0kg are mixed in a mixer, sent to a granulator for high temperature processing particulates. Then take 100kg of the prepared masterbatch, wire drawing, cold molding, cutting and setting, and then processing and drawing into a brush, you can get such image 3 The brush-shaped elastic filler shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com