Non-flash die for extruding aluminum alloy shell parts

A flash-free, aluminum alloy technology, applied in the direction of metal extrusion dies, etc., can solve the problems of reducing the service life of the die, wasting materials and energy consumption, and increasing the processing cost of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

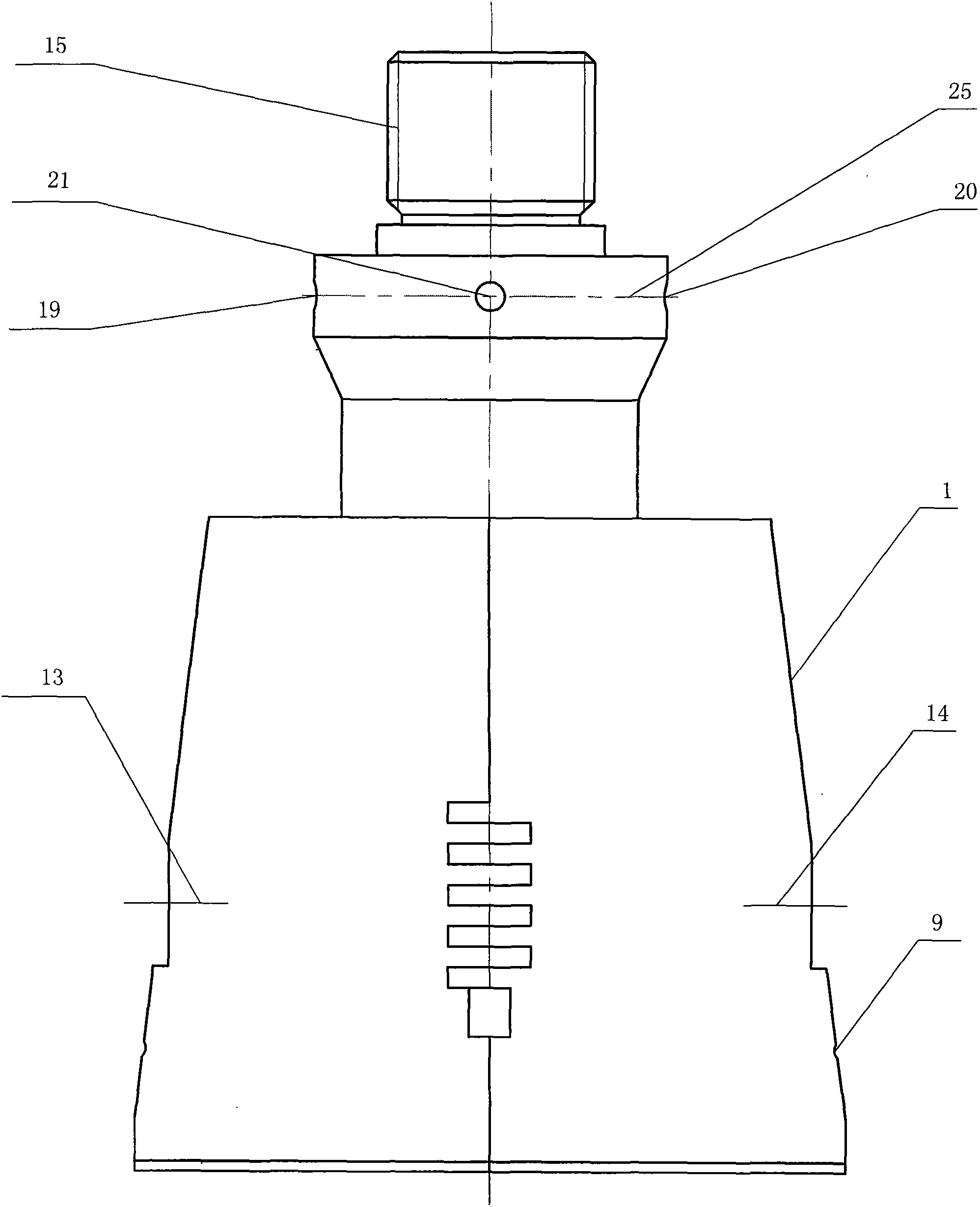

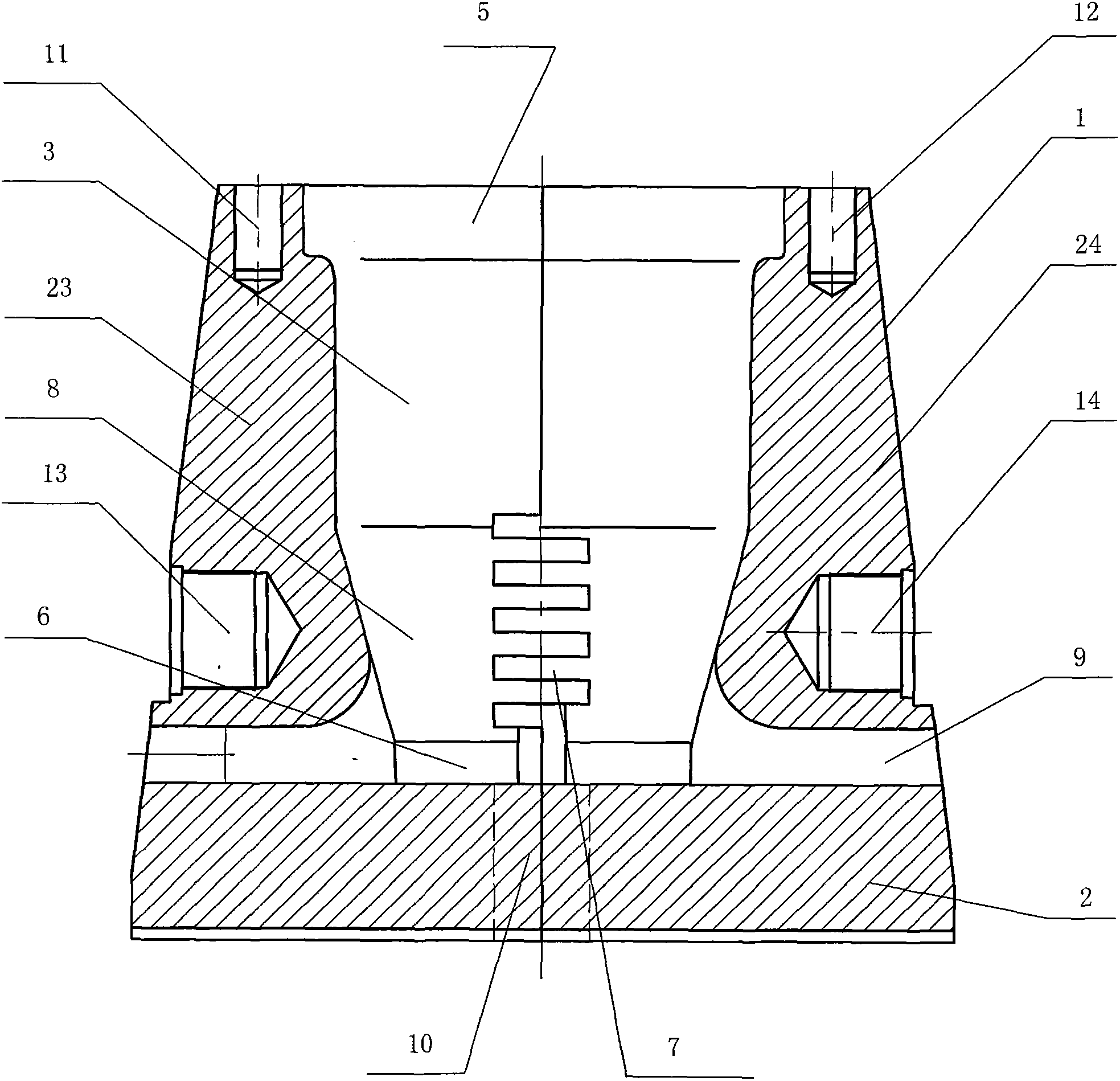

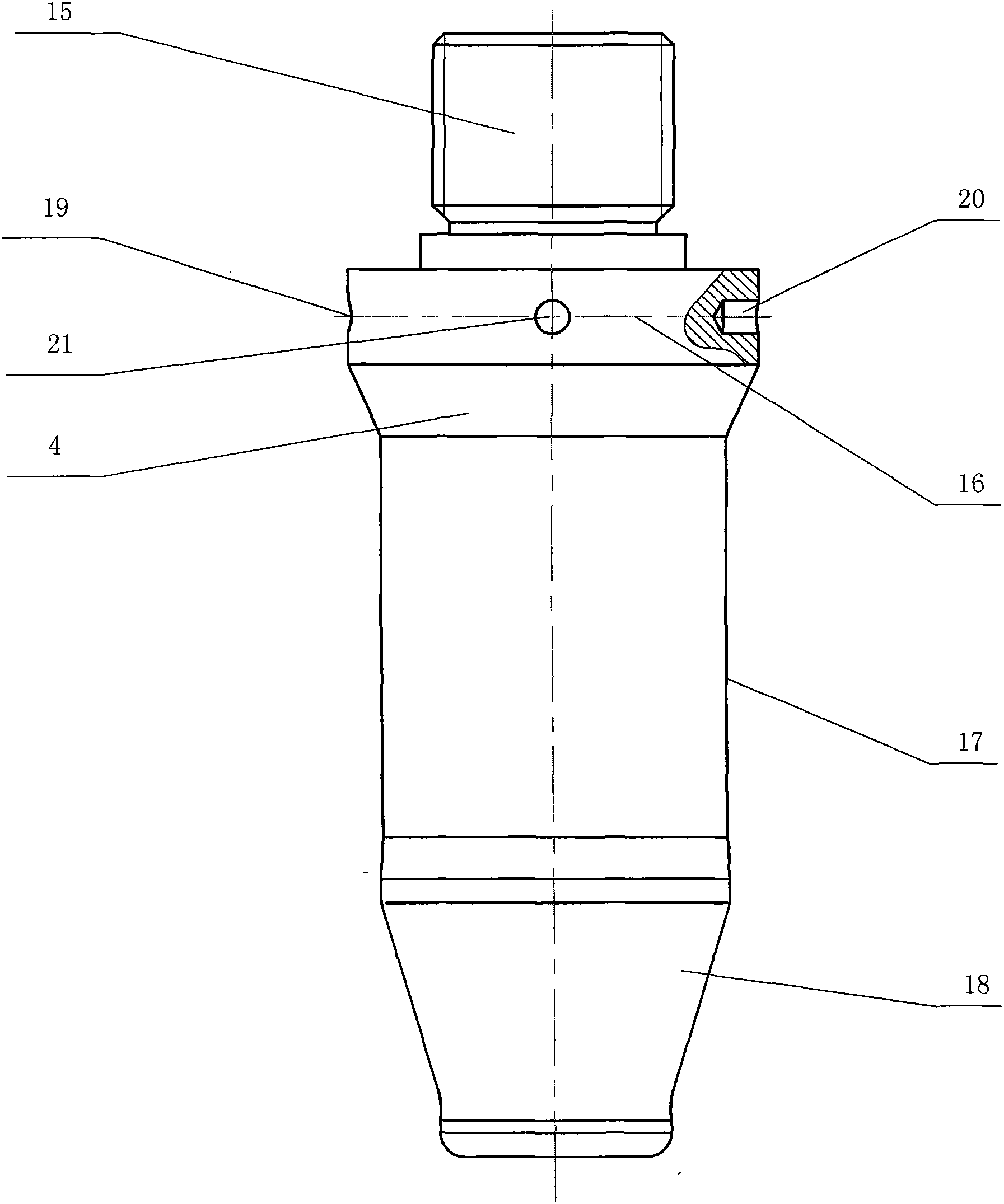

[0028] figure 1 , 2 , 3. shows the overall structure of the non-flash mold and the structure diagram of the die and punch. The position and connection relationship of each part must be correct.

[0029] Die 1 is in the shape of a forward cone, and the middle interior is a cavity, which is composed of cavity upper neck 5, cavity forming part 3, cavity tapered part 8, and cavity lower neck 6. There are curved teeth 7 on the part 8, the first and second installation and positioning holes 13, 14 are provided on the left and right sides of the die, the first and second lifting screw holes 11 and 12 are provided on the upper part, and the fork forming is provided on the lower part of the die. Part 9, bottom surface tooth 10; punch 25 is a reverse cone shape, from top to bottom is punch neck 16, punch tapered part 4, punch forming part 17, punch extension part 18, in the punch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com