Checking tool capable of measuring 0.7-dimension end surface teeth

A technology for measuring end and size, which is applied in the field of inspection tools that can measure the 0.7 size of the end face tooth, can solve the problem of inaccurate measurement of the end face tooth 0.7, and achieve the effects of reliable measurement results, accurate measurement results and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings.

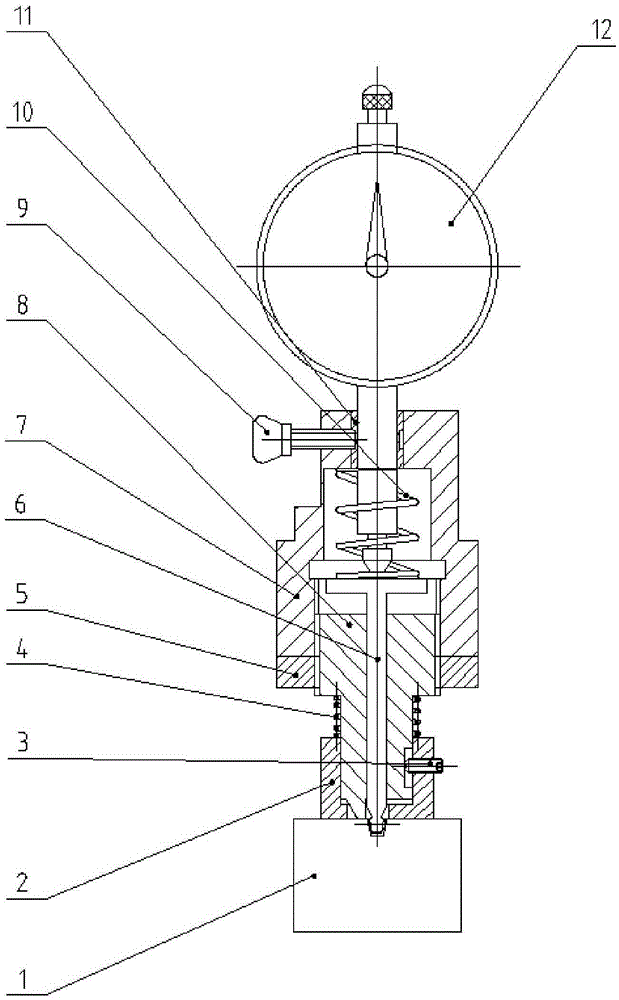

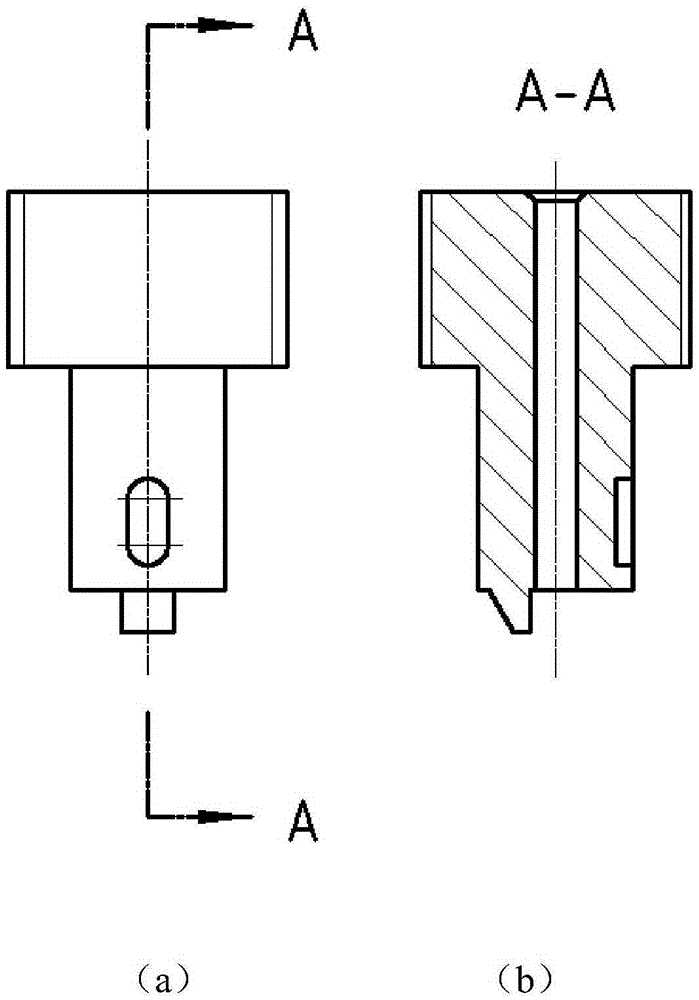

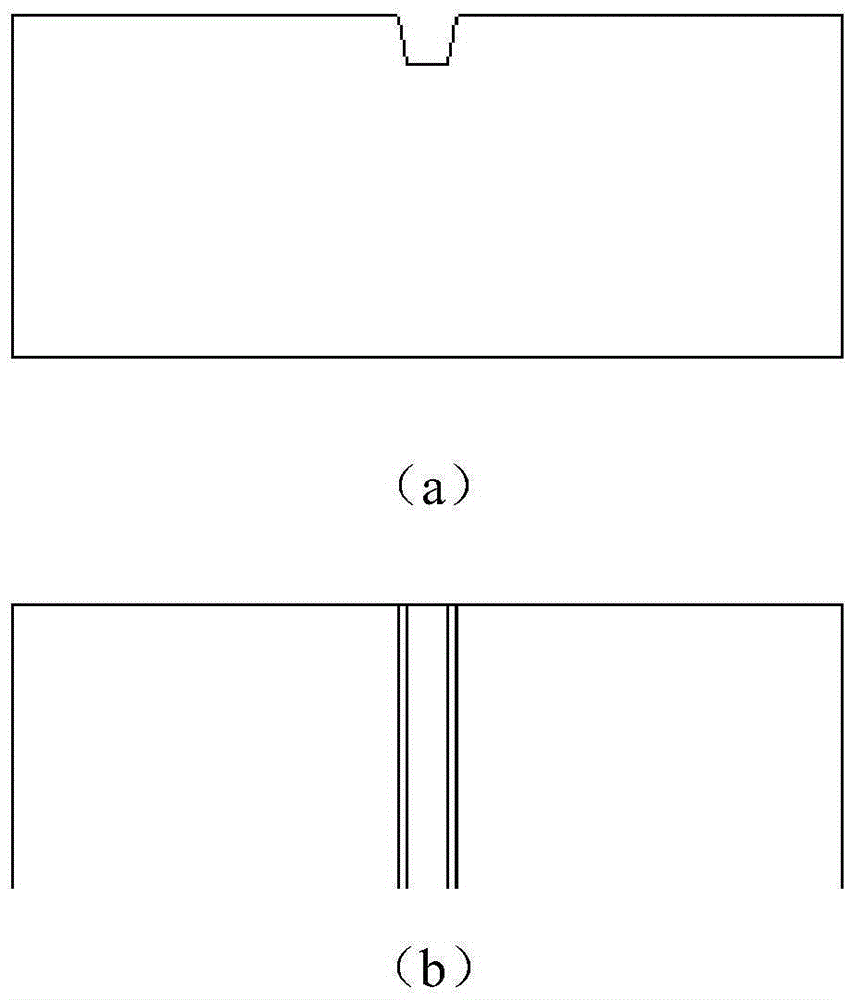

[0039] Such as Figures 1 to 6 As shown, the present invention is a kind of inspection tool that can measure the size of 0.7 end face teeth, including guide sleeve 2, measuring head 6, shaft sleeve 7, guide sleeve 8 and dial indicator 12; In the cavity, one end of the shaft sleeve 7 is fixedly set on the sleeve of the dial indicator 12, and the other end is fixedly set on one end of the guide sleeve 8, and the center of the guide sleeve 8 is provided with a guide hole with two openings along its axial direction. The probe 6 is arranged in the hollow cavity of the shaft sleeve 7 and the guide hole of the guide sleeve 8, the probe 6 can slide along the guide hole of the guide sleeve 8, and one end of the probe 6 is in contact with the measuring head of the dial gauge 12, The other end protrudes out of the guide hole of the guide sleeve 8 , the guide sleeve 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com