Processing method of tapered tooth spherical-involute tooth-form slant straight bevel gear

A spherical involute and straight-toothed bevel gear technology, which is applied in the direction of manufacturing tools, metal processing equipment, gear tooth manufacturing devices, etc., can solve the problems of less application, more complex machine tools than straight gears, and lower production efficiency, and achieve machine tool Simple movement, simple structure, and simplified sharpening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

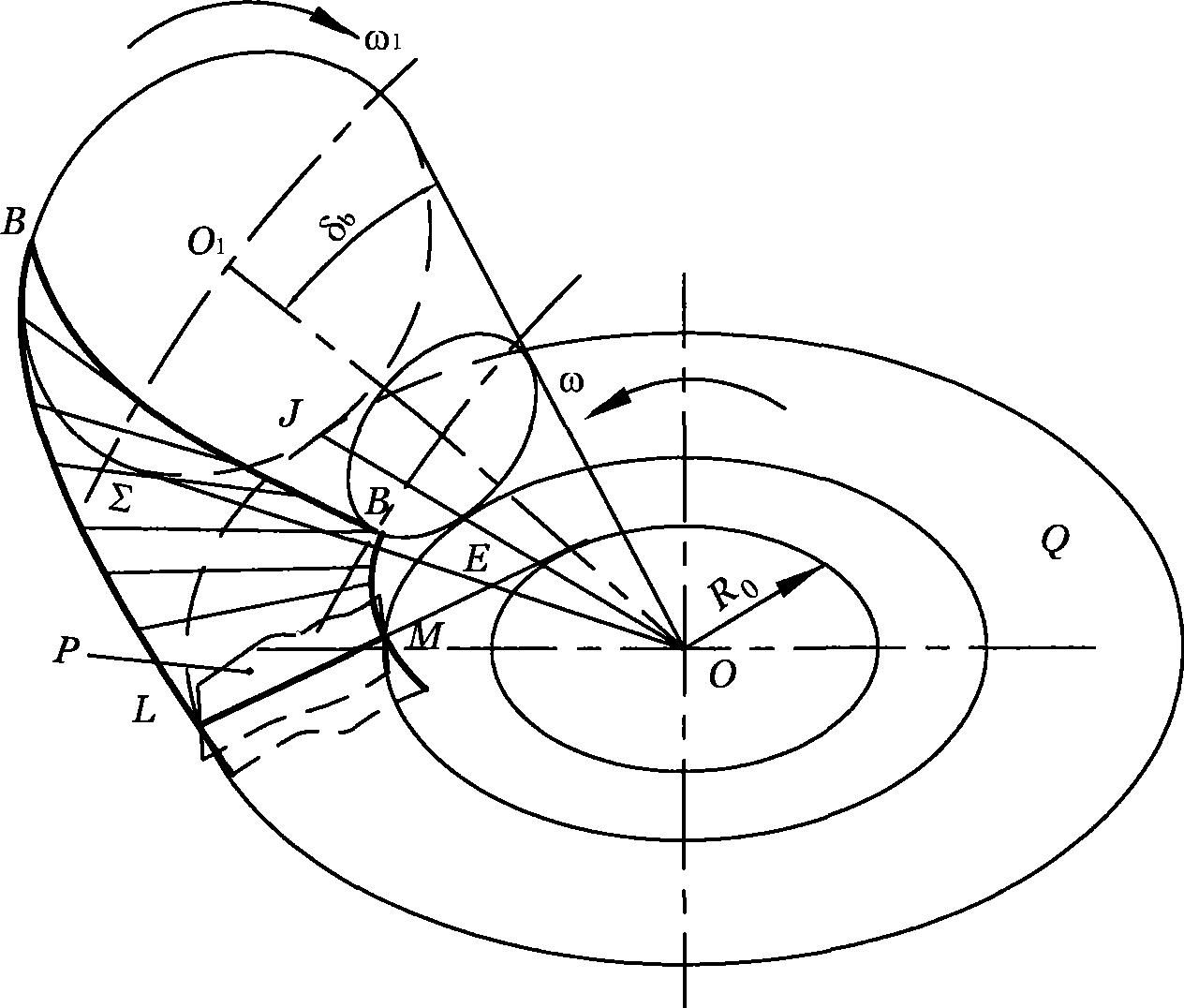

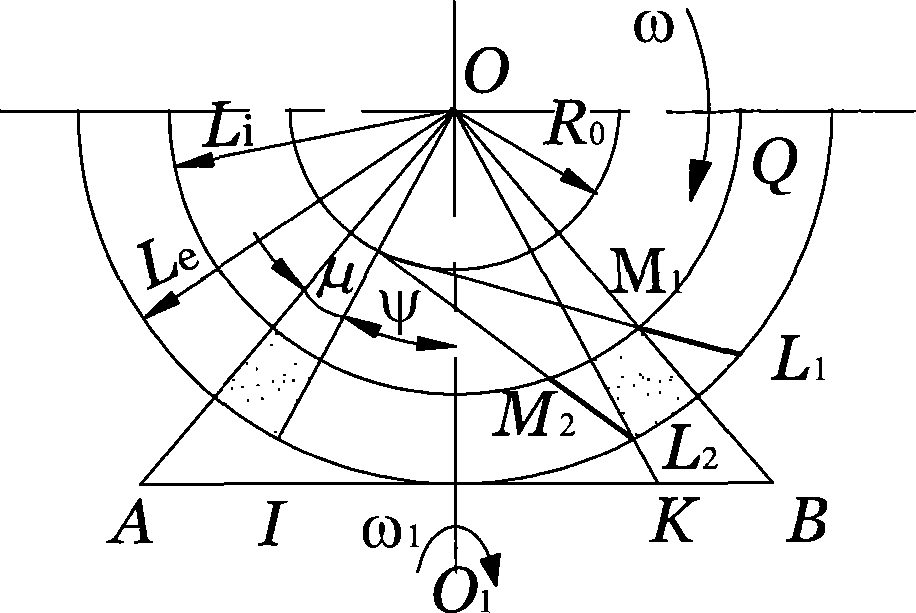

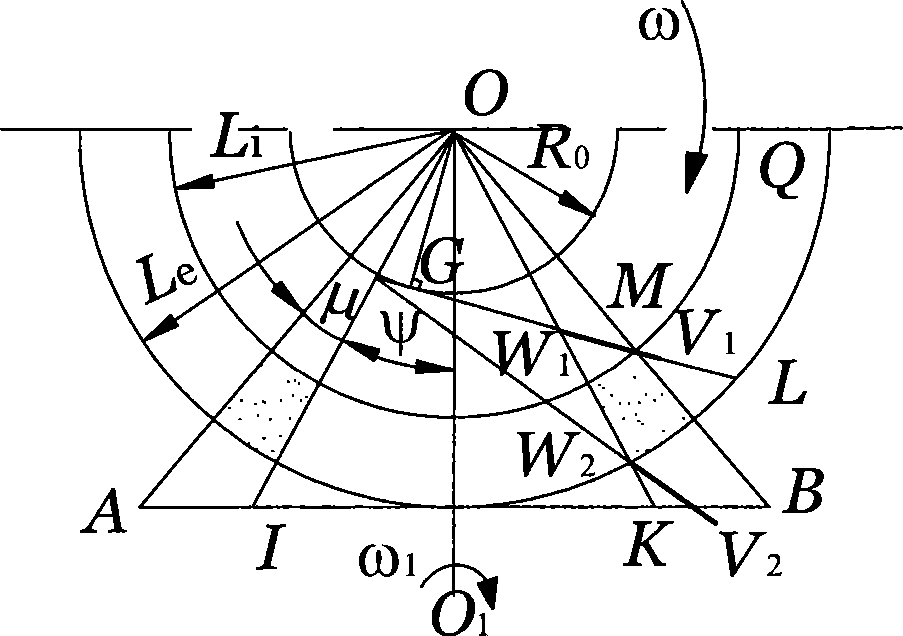

[0078] To implement the above-mentioned shrink-tooth-making spherical involute tooth profile helical straight bevel gear processing method, one is to design a new machine tool, and the other is to implement shrink-tooth-making spherical involute tooth profile oblique on the existing multi-axis CNC machining center machine tool. Straight bevel gears. No matter which implementation method is adopted, the base cone angle must be δ b The tooth blank base cone is tangent to the spherical great circle plane Q and completes the relative pure rolling. All must satisfy the spherical great circle plane Q rotation angular velocity ω, tooth blank rotation angular velocity ω 1 It is a constant-ratio constant-speed rotation movement, avoiding over-cutting movement v W = R 0 ω cos 2 ωt ...

Embodiment 2

[0084] Double-station, double-cutterhead continuous gear division precision cutting helical straight bevel gear machine tool

[0085] For large batches and high-efficiency gear cutting, reducing the number of installations, continuous tooth division, and simultaneous cutting of both sides of the tooth surface are effective means to improve the efficiency of gear cutting.

[0086] Refer to Picture 10 , Shown in the figure is the top view of a double-station, double-cutterhead continuous fine-cutting helical bevel gear machine with a horizontally placed workpiece axis and a horizontal layout. The machine tool has the first and the second two stations, I and II two cutter heads. The two bevel gears to be processed are installed on the two ends of the same workpiece shaft in the workpiece holder 13, so the rotation direction and angular velocity are the same when the gear is cut. The transformation is rotated by the workpiece holder 13 along with the turntable 3 O * The rotation is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com