Large-power wind driven generator step-up gearbox with electric barring device

A wind turbine and electric turning technology, which is applied to wind turbine components, wind turbines, electromechanical devices, etc., can solve the problems that the fan cannot manually turn the blades and the weight of the whole machine is large, so as to avoid adverse effects and have a compact structure. , the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

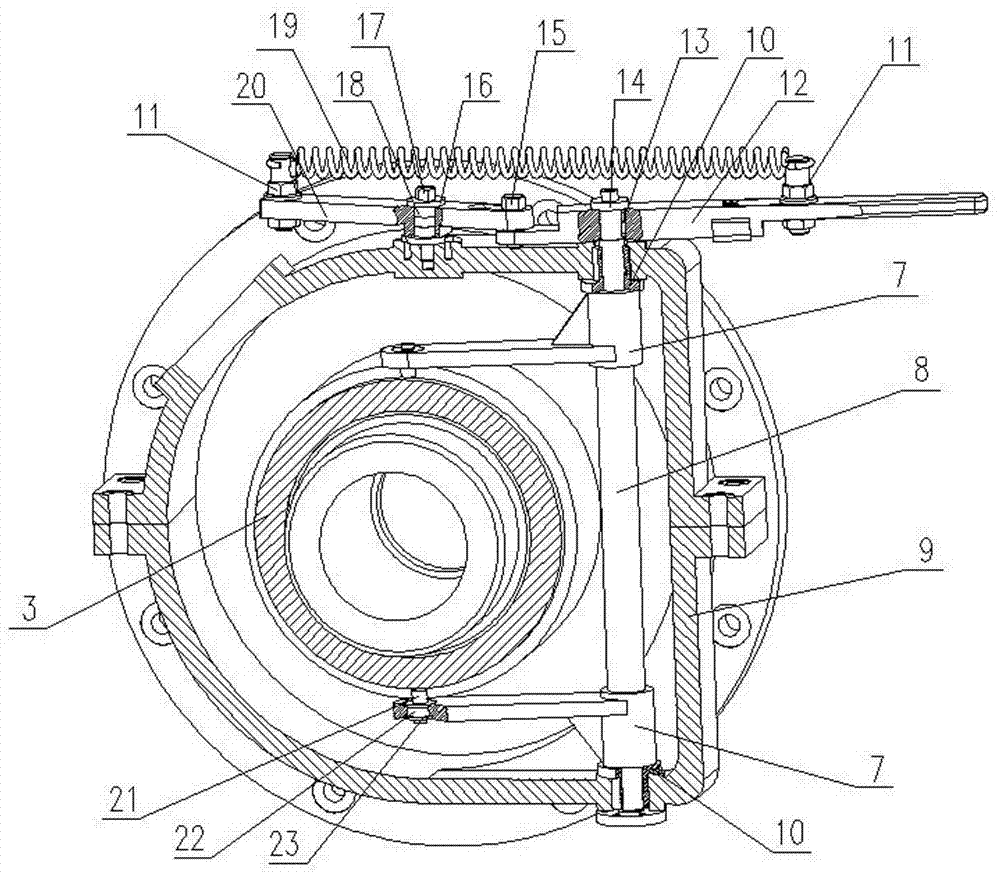

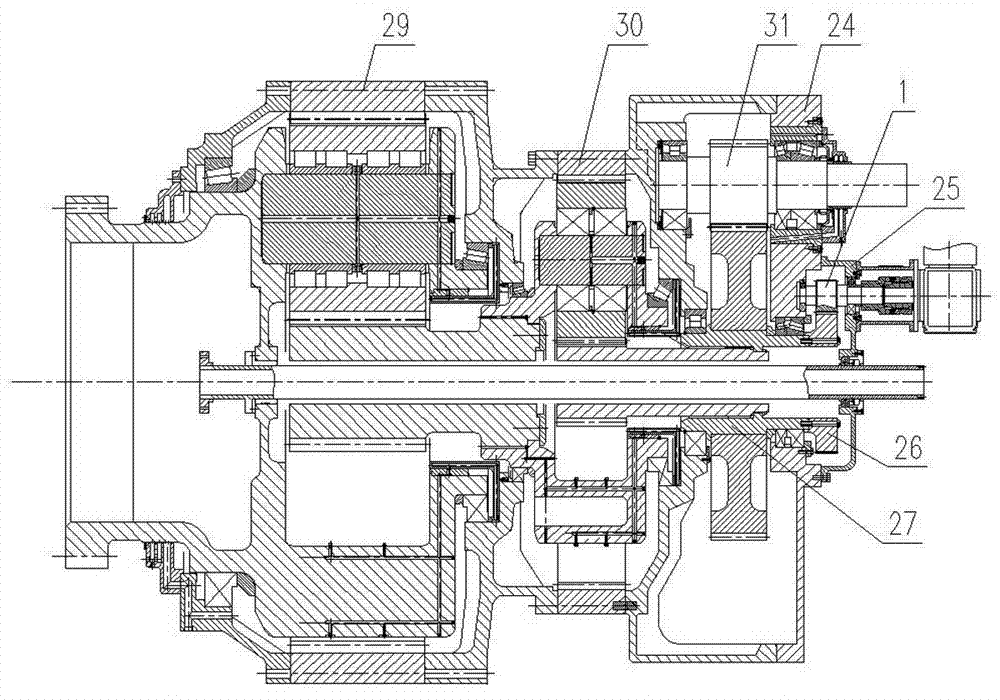

[0020] The accompanying drawings disclose the specific structures of the embodiments of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

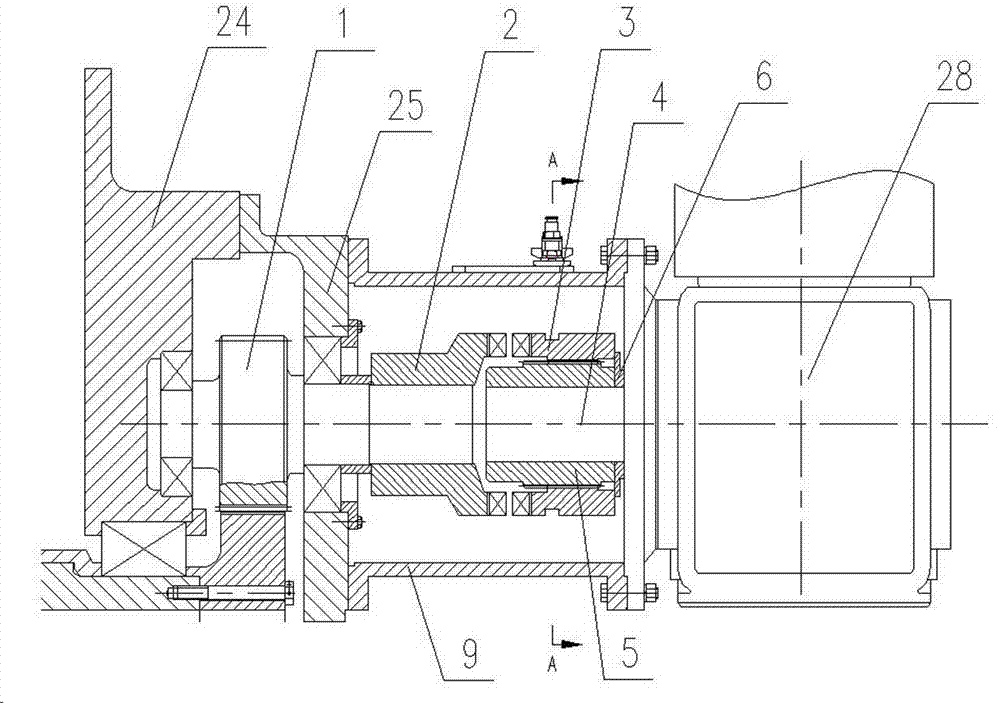

[0021] Depend on figure 1 , figure 2 Visible, the present invention is that a kind of power is greater than 5MW and is provided with the speed-increasing gear box of wind-driven generator of electric turning gear, and it is that existing high-power wind-driven generator speed-up gear box has done following improvement:

[0022] The high-speed end bearing seat 24 of the speed-increasing gearbox is provided with a transparent cover 25, and the transparent cover 25 is provided with the casing 9 of the clutch device, and the driving motor 28 is fixedly installed on the casing 9 of the clutch device.

[0023] The barring large gear 26 is located between the high-speed end bearing seat 24 and the transparent cover 25, the barring large gear 26 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com