Technique for producing and processing chamfering tool for cylindrical gear double-side tooth profile

A technology of chamfering tools and cylindrical gears, which is applied to gear tooth manufacturing tools, gear tooth manufacturing devices, components with teeth, etc., can solve the problems of increasing errors, increasing costs, increasing workload, etc. Less, the method is simple, the precision is reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

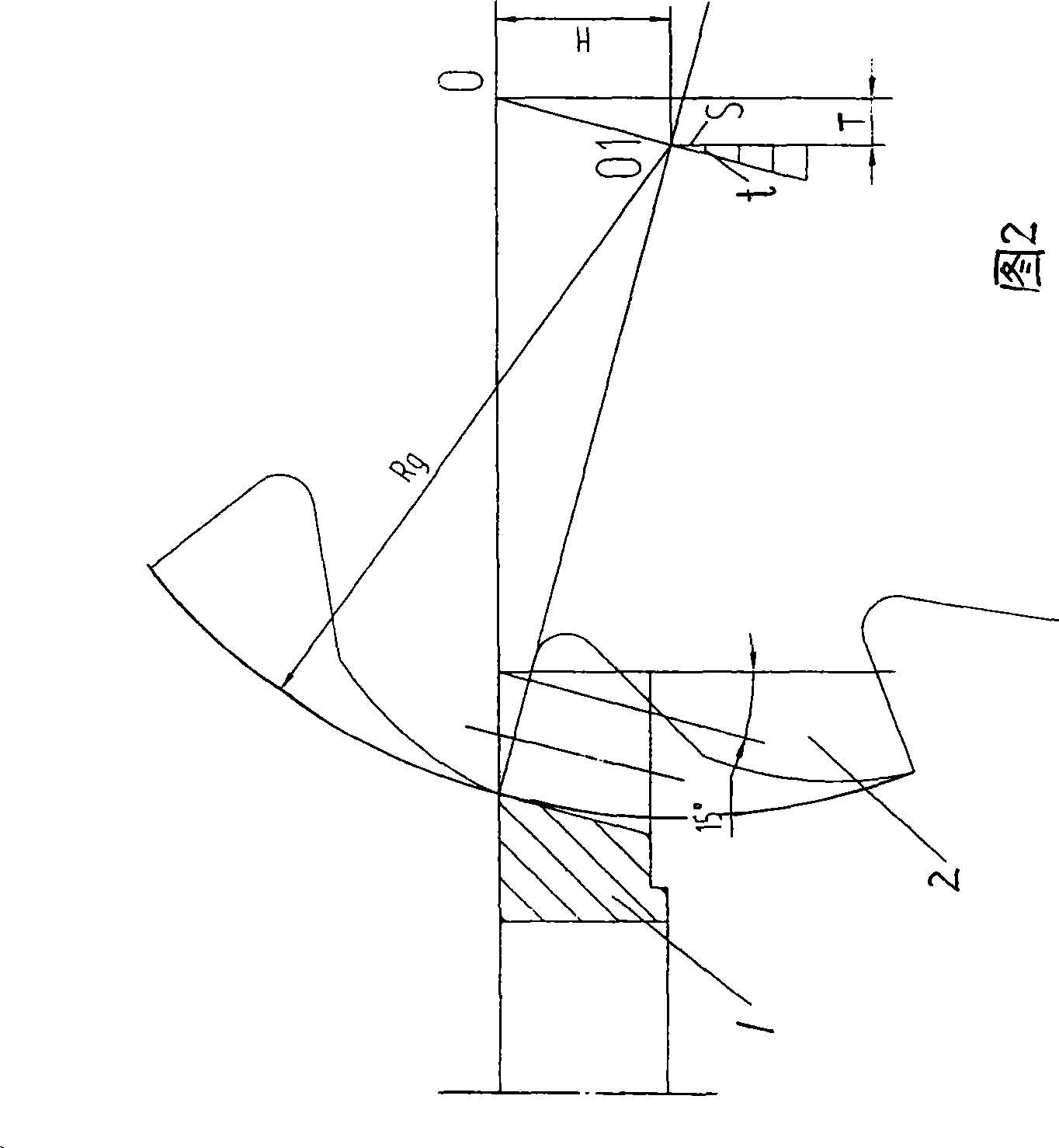

[0021] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0022] The processed chamfering tool is shown in Figure 1: its working parameters are as follows:

[0023] Modulus m n = 3,

[0024] Number of teeth Z=36,

[0025] pressure angle α n = 20°,

[0026] Circle-splitting helix angle β=17°right-handed.

[0027] The parameters of the processed chamfering tool are as follows:

[0028] modulus m=3,

[0029] Number of teeth Z q = 46,

[0030] pressure angle α n = 20°,

[0031] Left helix angle β L = 37° left-handed,

[0032] Right helix angle β R = 3° dextrorotation,

[0033] Addendum circle diameter D e =155.105±0.02,

[0034] Root circle diameter D i =141.605±0.1,

[0035] Base circle diameter D b =134.867,

[0036] Thickness S of big end split circle normal chord n =8.069±0.02.

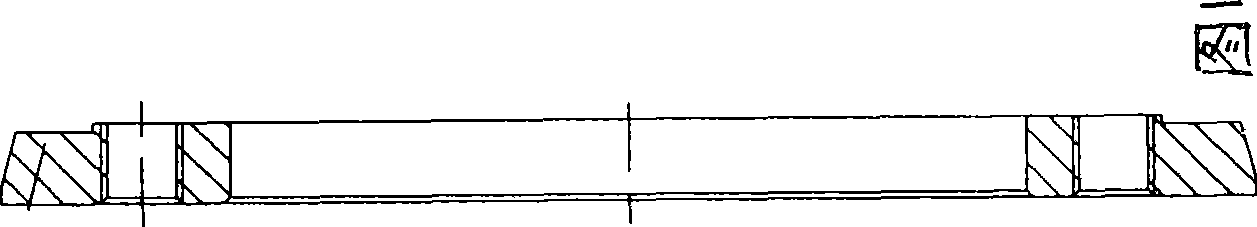

[0037] The processing steps include: forging, turning, drilling, tapping, gear hobbing, heat treatment, f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com