Safety belt device and safety belt winder

A technology for a seat belt retractor and an installation column, which is applied to belt tensioners and other directions, can solve problems such as the complex structure of the seat belt retractor, and achieve the effects of simple structure, small occupied space, and small number of parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

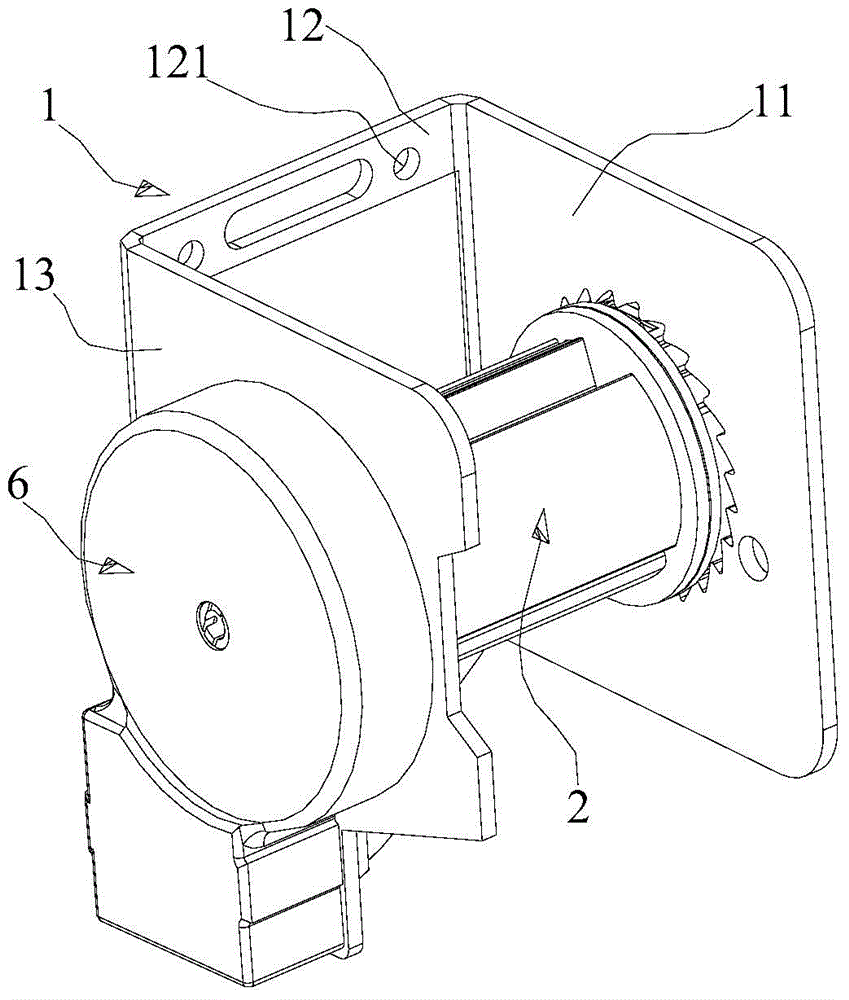

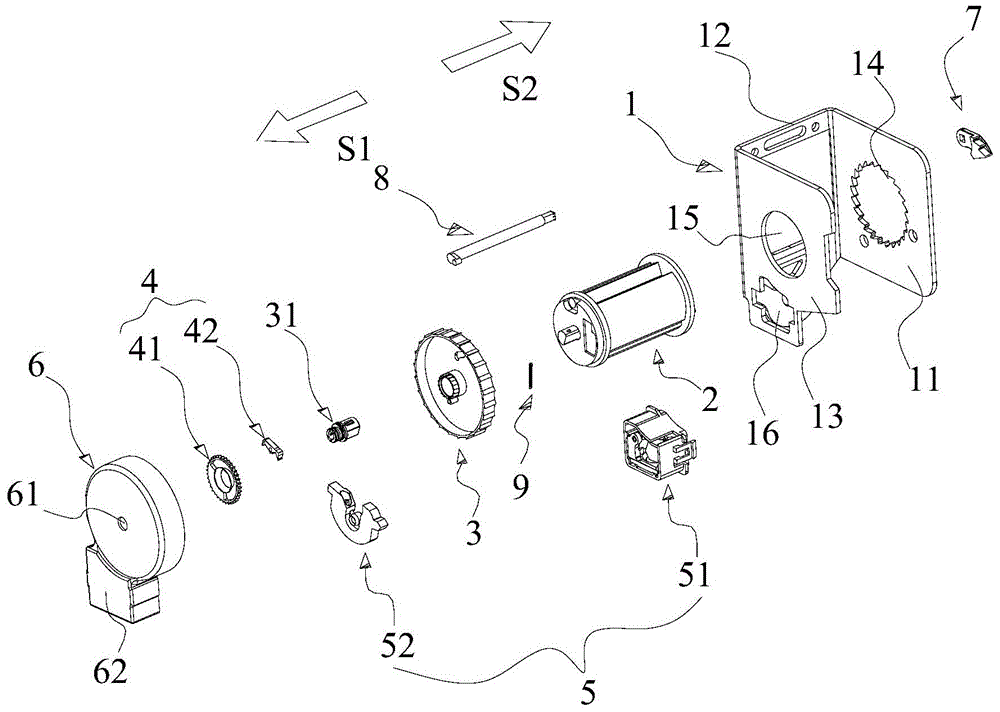

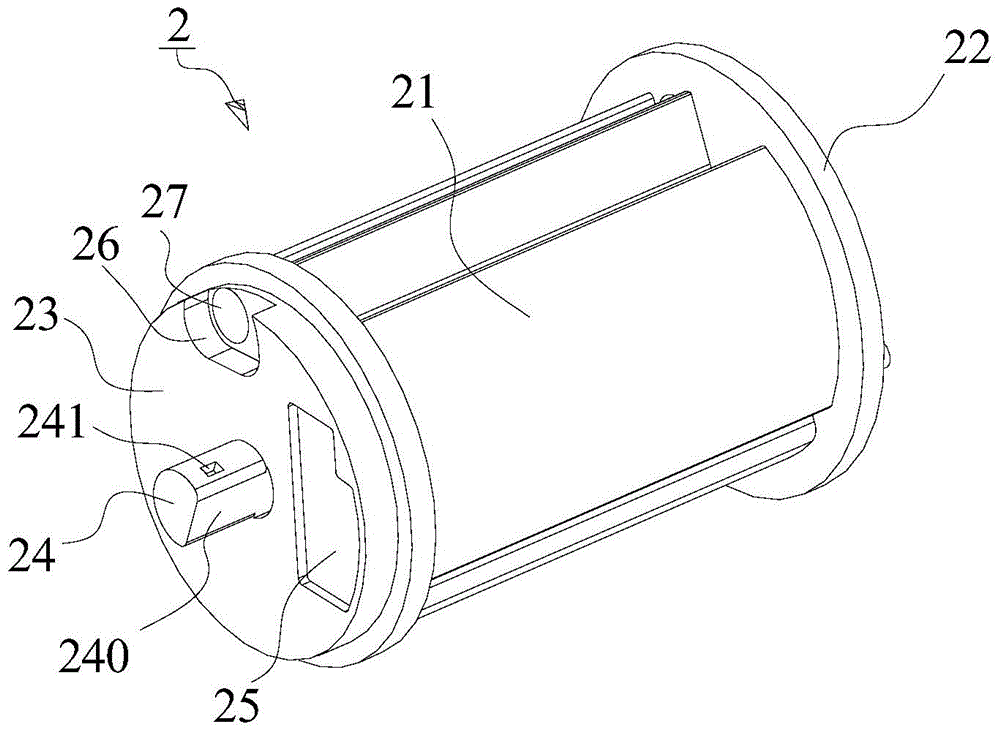

[0059] In this example, the seat belt retractor will be described in detail. To make the subsequent description more concise and clear, pulling the webbing inward to tighten the webbing is referred to as winding the webbing or pulling back the webbing, and pulling the webbing out to release the webbing is referred to as Release the webbing or pull out the webbing, such as figure 1 The overall three-dimensional schematic diagram of the seat belt retractor given, and figure 2 The disassembled schematic diagram of the safety belt retractor is given, which includes the reel 2, the frame 1, the ratchet 3, the locking device, and the switching device 4; for the convenience of description, the S2 direction in the figure is defined as the right side, and the S1 direction is defined as the left side .

[0060] During the research and development process, the inventor found that the existing safety belt retractor adopts a complex structure scheme to realize its ALR and ELR functions, ...

Embodiment 2

[0096] This example provides a seat belt device, including the seat belt retractor mentioned in the foregoing embodiment 1, a webbing wound on the reel 2 of the seat belt retractor, and slidably arranged on the webbing The tongue on the top, and the buckle that is arranged on the vehicle body or the vehicle seat and fastened with the tongue.

[0097] Because the seat belt retractor has been specifically introduced in Embodiment 1, and the webbing, tongue, buckle, etc. are well known to those skilled in the art, therefore, no more details are given.

[0098] Likewise, with the seat belt device provided in this example, since it includes the innovative seat belt retractor in Embodiment 1, the seat belt device can effectively switch between the ALR mode and the ELR mode. The structure is simpler, the number of parts is small, the cost is low, and the occupied space is small. Material costs and assembly costs are lower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com