Machining method for profile countersink drill

A processing method and a countersinking technology, which are applied in the processing field of countersinking, can solve the problems of not being able to well guarantee the surface accuracy requirements of the countersinking, difficult to measure and detect, etc., and achieve high precision, ensure the surface accuracy requirements, and ensure processing. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

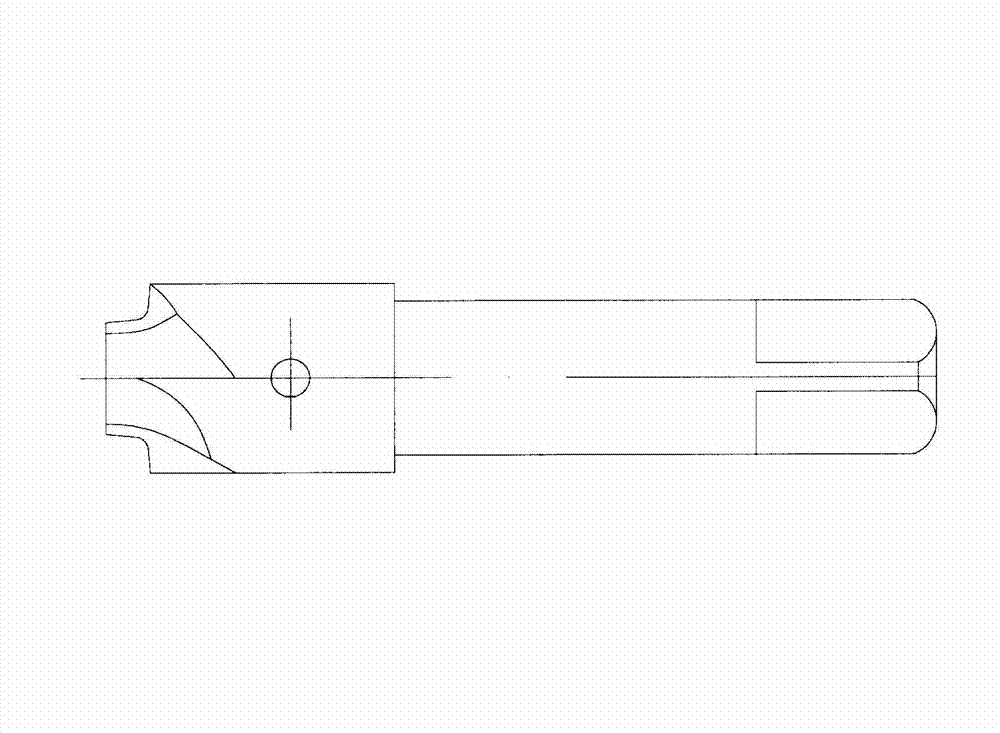

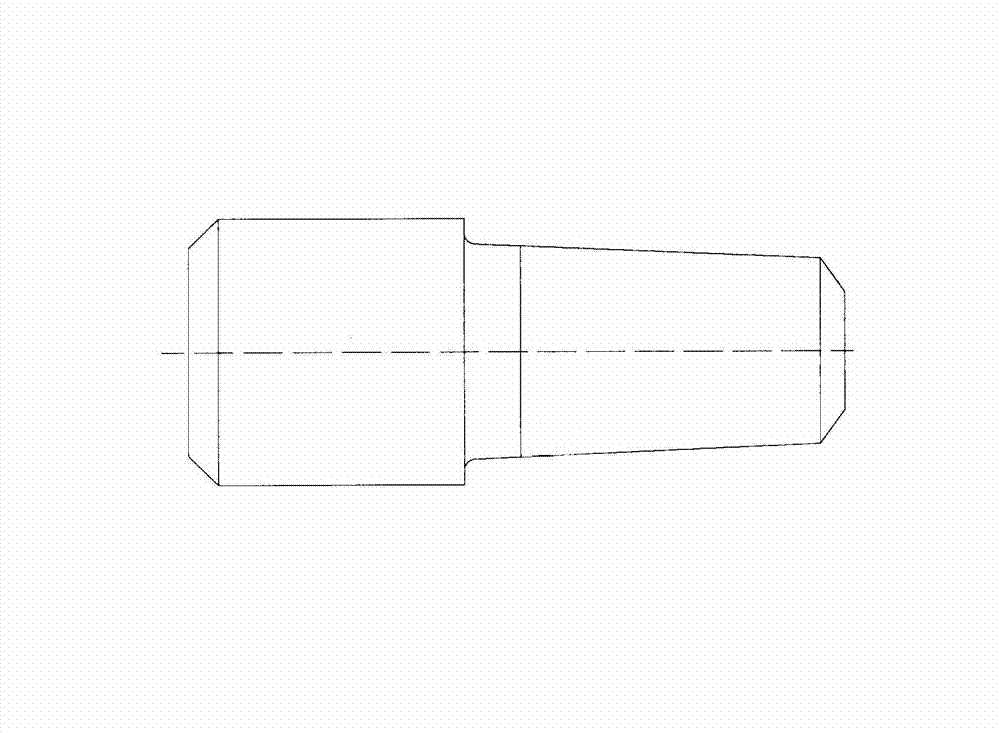

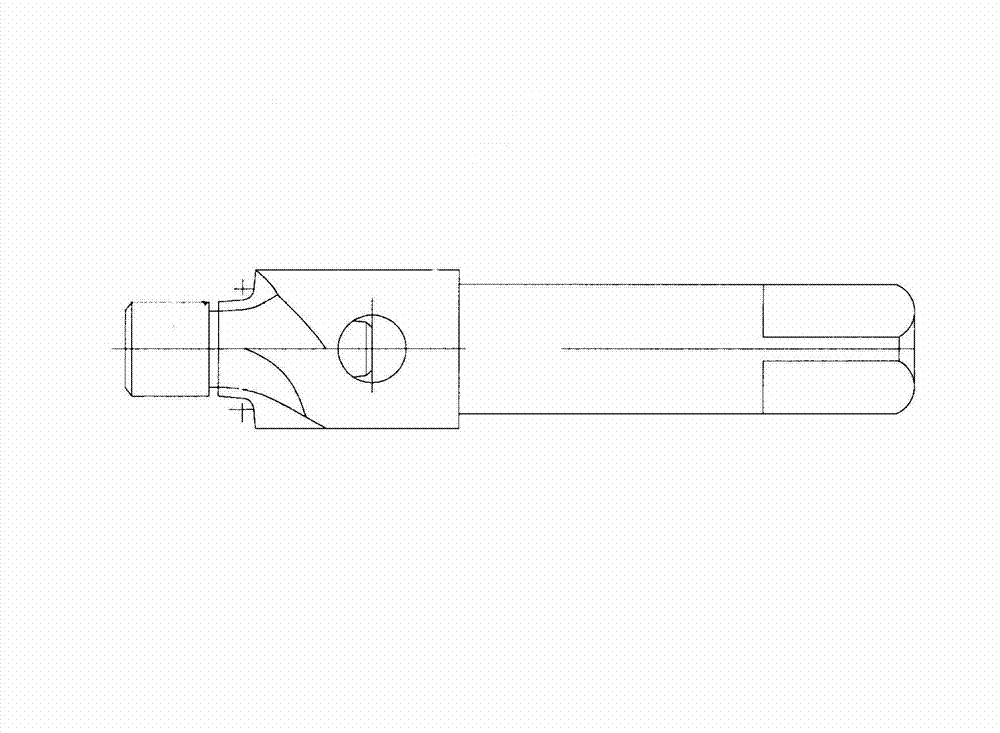

[0025] like Figure 5 As shown, now take d=Φ6.2R0.7 profile countersink as an example to illustrate the processing method of profile countersink, which includes the following steps:

[0026] 1) Align the blank of the cutter body including the blade and the tail handle, drill and ream the 1:50 taper hole to the size, and use the 1:50 taper hole as the reference for the center hole of the tail;

[0027] 2) Car shape: the top car is formed, the outer circle of the blade is ground 0.4mm, the outer circle of the tail shank is ground 0.4mm, and the profile adopts a sample with a uniform reserve of 0.2mm, which can ensure the uniform reserve of the profile, that is, proofread with the sample For the countersinking surface, leave 0.2mm evenly between the template and the countersinking surface;

[0028] 3) Milling tooth shape: Mill the tooth shape of the angled surface according to the requirements of the drawing, leaving the amount of relief grinding K=2.1;

[0029] 4) Coarse shove...

Embodiment 2

[0037] like Figure 5 As shown, now take d=Φ6.2R0.7 profile countersink as an example to illustrate the processing method of profile countersink, which includes the following steps:

[0038] 1) Align the blank of the cutter body including the blade and the tail handle, drill and ream the 1:50 taper hole to the size, and use the 1:50 taper hole as the reference for the center hole of the tail;

[0039] 2) Car shape: the top car is formed, the outer circle of the blade is ground 0.5mm, the outer circle of the tail shank is ground 0.5mm, and the profile adopts a sample with a uniform reserve of 0.3mm, which can ensure the uniform reserve of the profile, that is, proofread with the sample For the countersinking surface, leave 0.3mm evenly between the sample plate and the countersinking surface;

[0040] 3) Milling tooth shape: Mill the tooth shape of the angled surface according to the requirements of the drawing, leaving the amount of relief grinding K=2.1;

[0041] 4) Coarse s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com