Tooth form geometrical parameter measurement method for online machining of large-diameter multi-thread ring gauge

A multi-thread, geometric parameter technology, used in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of high cost of testing equipment, inability to meet the needs of single-piece production, etc. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below with reference to the drawings and specific embodiments.

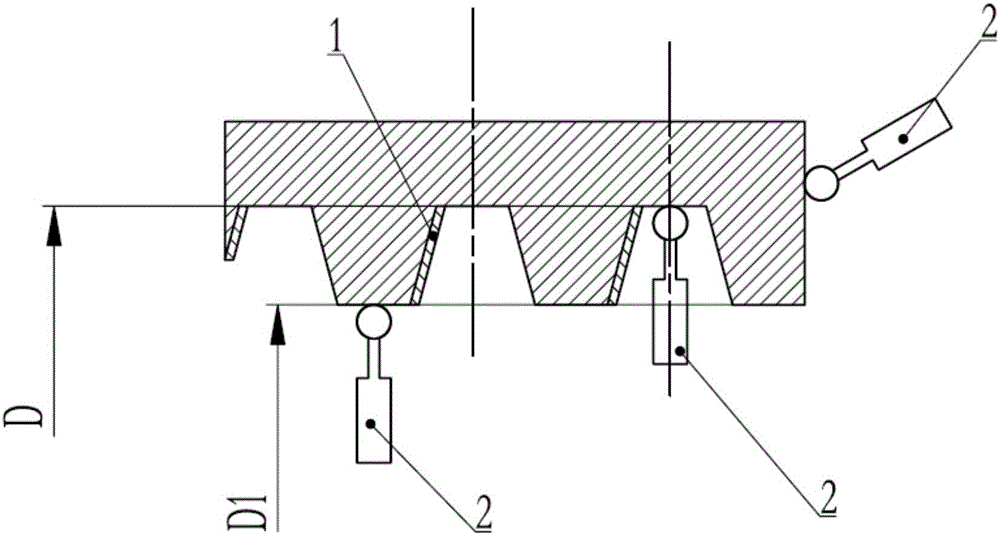

[0058] The present invention is a method for measuring the geometric parameters of the online processing tooth profile of a large-diameter multi-threaded ring gauge. The laser measuring equipment used is a three-coordinate laser measuring machine. This type of equipment requires both dot measurement and laser scanning measurement functions and is portable and can It is convenient to bring to the site, the specific operation steps are as follows:

[0059] Step one, lock the processing equipment so that the threaded ring gauge does not move or rotate in any direction;

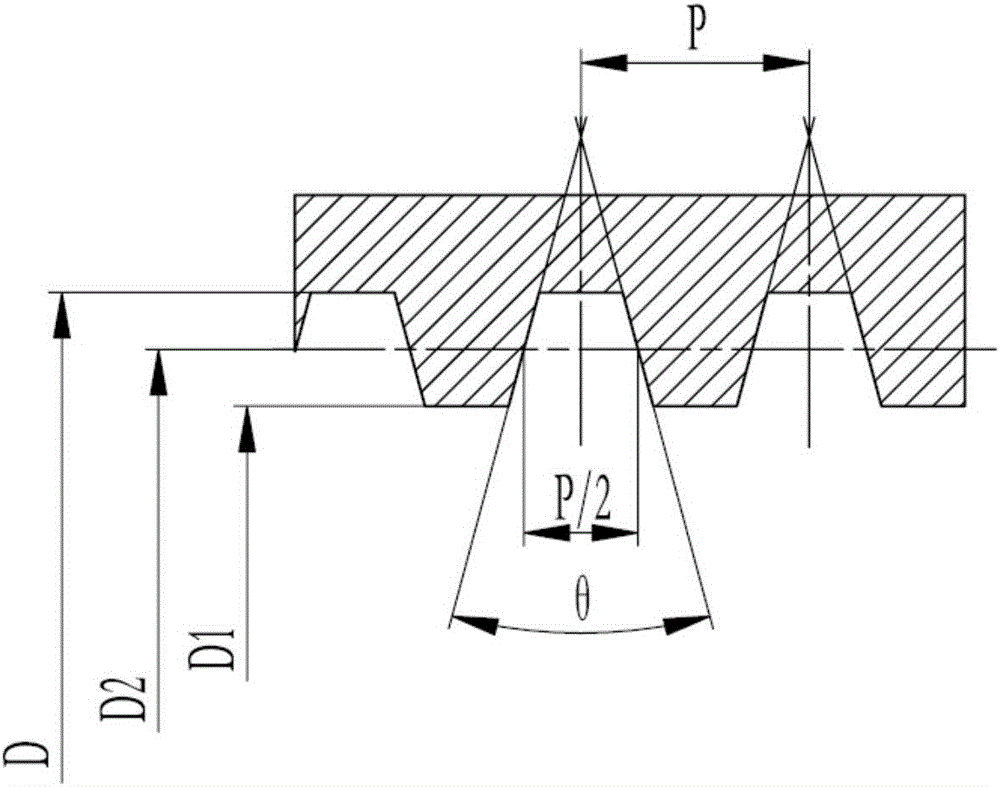

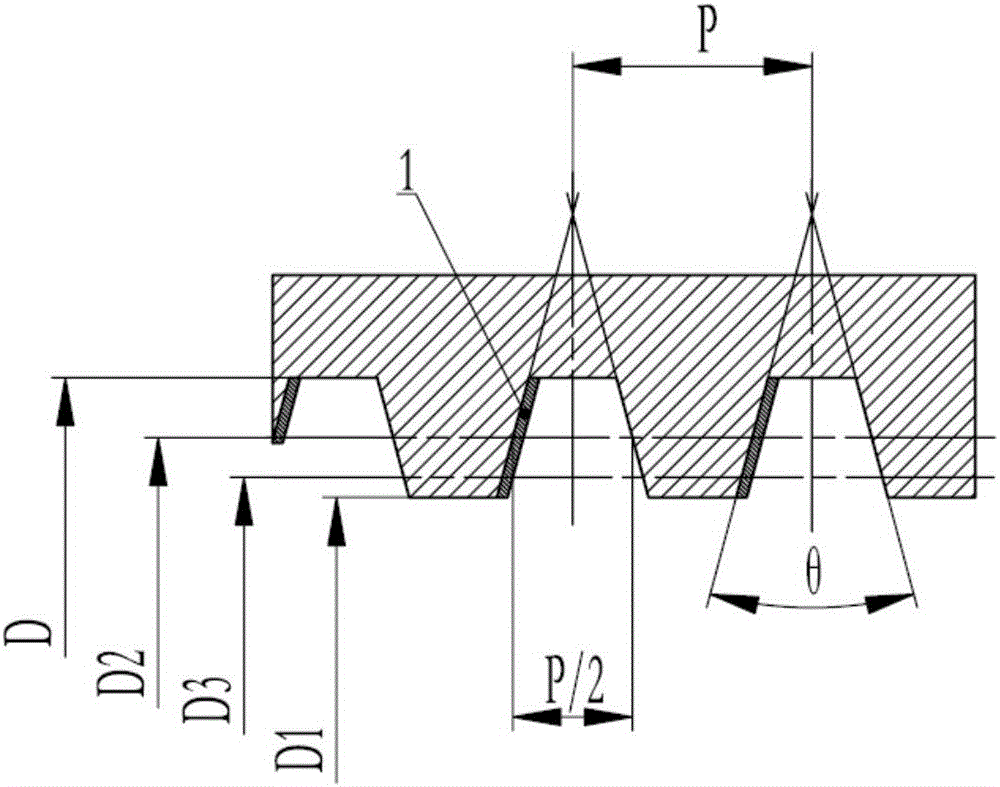

[0060] Step two, select the side head with appropriate diameter, measure the geometric parameters of the minor diameter D1 of the thread of the ring gauge and the major diameter D of the thread, and adjust the measurement standard of the part;

[0061] (1) Choose a side head with a suitable diameter s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com