Planetary multi-speed transmission method and device

A variable speed transmission, planetary technology, applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problems of high cost, large overall structure size, low transmission efficiency, etc., and achieve small size and weight, simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

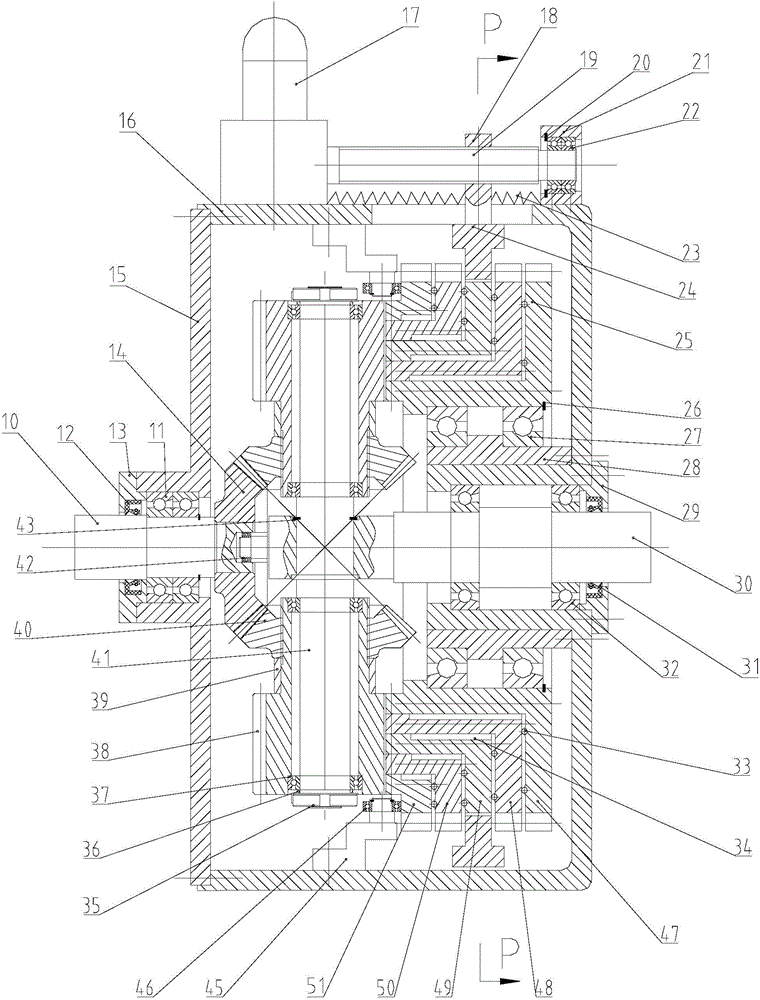

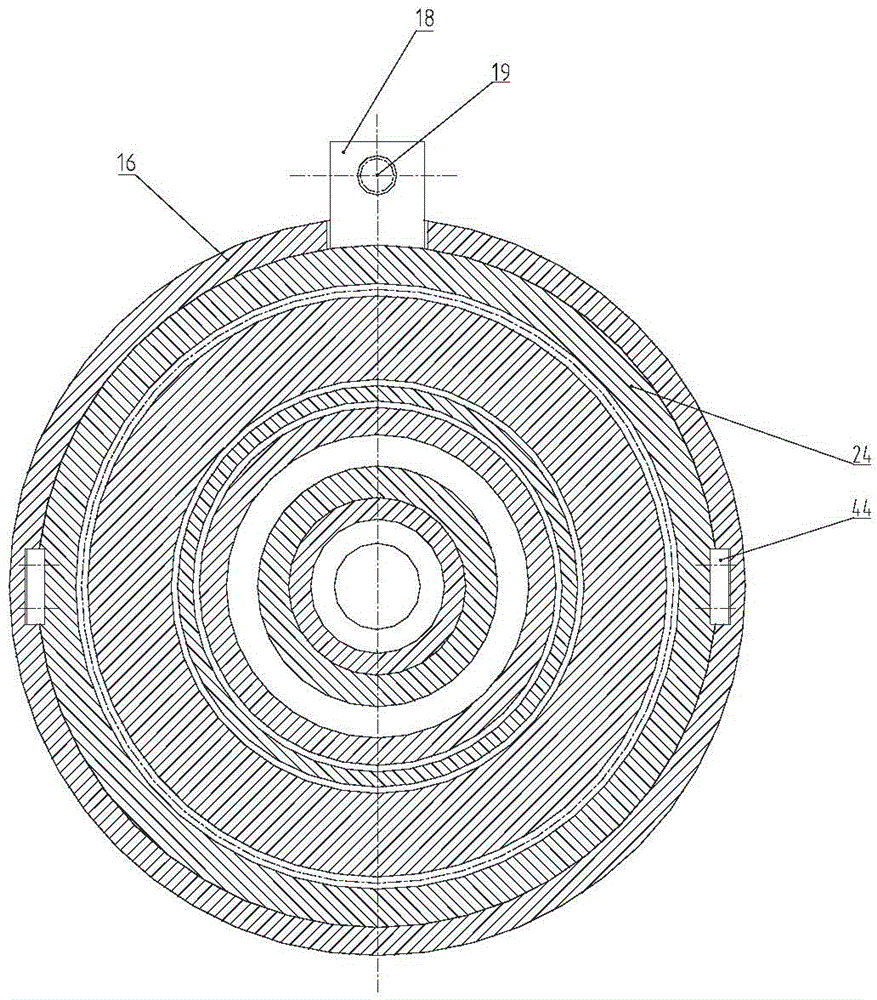

[0035] Such as figure 2 , 3As shown, the planetary multi-stage transmission device includes an input shaft 10, a first bearing 11, a first oil seal 12, an input shaft cover 13, a driving bevel gear 14, a box cover 15, a box 16, and a variable speed drive motor 17. Drive nut 18, drive screw 19, circlip for hole 20, screw support 21, second bearing 22, retractable dust cover 23, inner ring gear 24, face gear 25, circlip for second hole 26. The third bearing 27, the support sleeve 28, the output shaft cover 29, the output shaft 30, the second oil seal 31, the fourth bearing 32, the steel ball 33, the needle bearing 34, the round nut 35, the washer 36, the fifth bearing 37. Cylindrical gear 38, separation sleeve 39, driven bevel gear 40, rotating arm 41, sixth bearing 42, shaft circlip 43, guide flat key 44, support block 45, seventh bearing 46, first-stage sleeve Ring face gear 47, second stage ring face gear 48, third stage ring face gear 49, fourth stage ring face gear 50 an...

Embodiment 2

[0045] Figure 5 It is a structural schematic diagram of the planetary multi-stage variable speed transmission device of Embodiment 2. Such as Figure 5 Shown, with respect to embodiment 1 ( figure 2 ), this embodiment is to remove figure 2 Middle second stage ferrule face gear 48 and fourth stage ferrule face gear 50, support block 45, the seventh bearing 46, steel ball 33, needle roller bearing 34 are changed into centripetal thrust ball bearing 64 and form. This structure has three output speeds, which reduces the installation difficulty of the support block 45 and the seventh bearing 46, and there is a neutral gear when the inner ring gear 24 moves from one ring face gear to the other ring face gear during the shifting process Bit, can improve the smoothness of gear shifting.

[0046] The present invention can realize different transmission ratio requirements by changing the number of teeth of each gear, and also can make the ferrule end face gears sequentially fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com