Technical bogie

A technology of process bogies and frames, applied in the field of process bogies, can solve problems such as lack of guiding function of guide rails, inconvenient operation, deflection of support columns, etc., and achieve convenient adjustment of size readings, strong practicability, and avoidance of deflection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

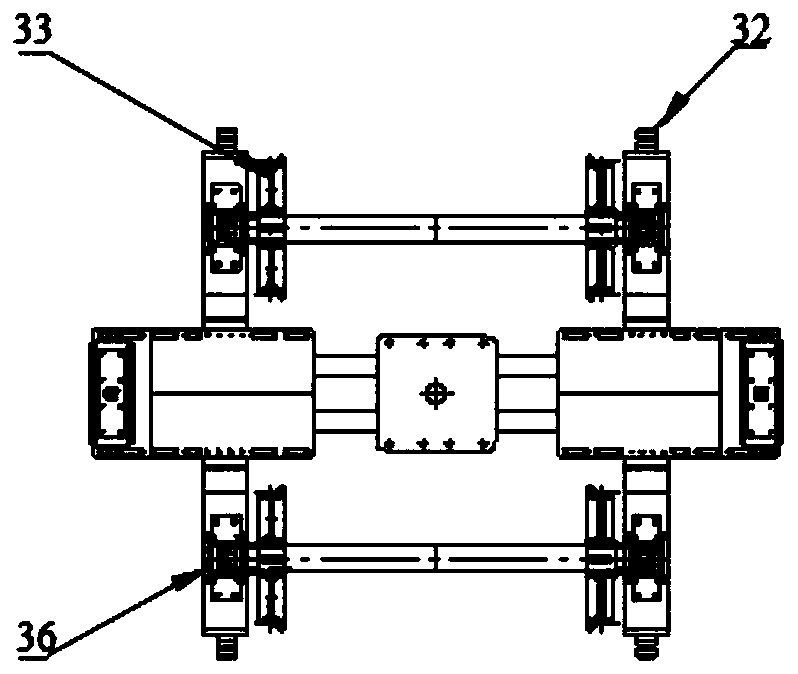

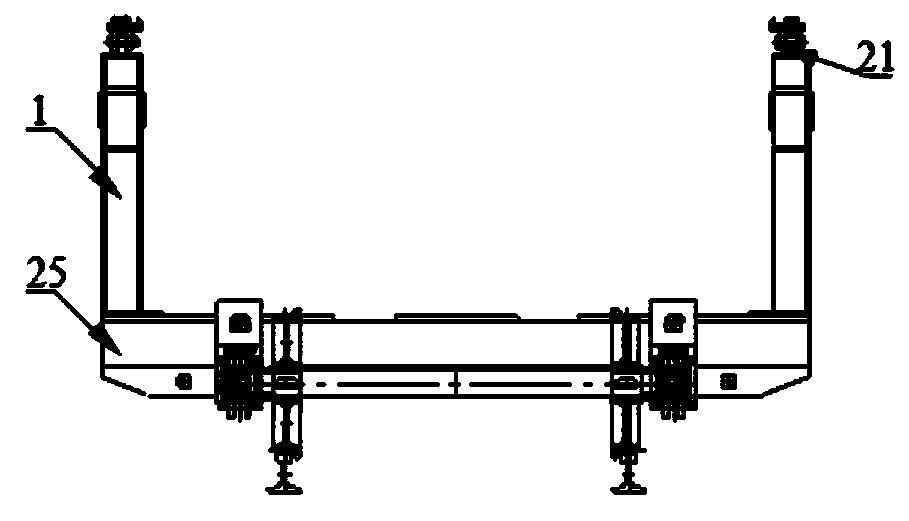

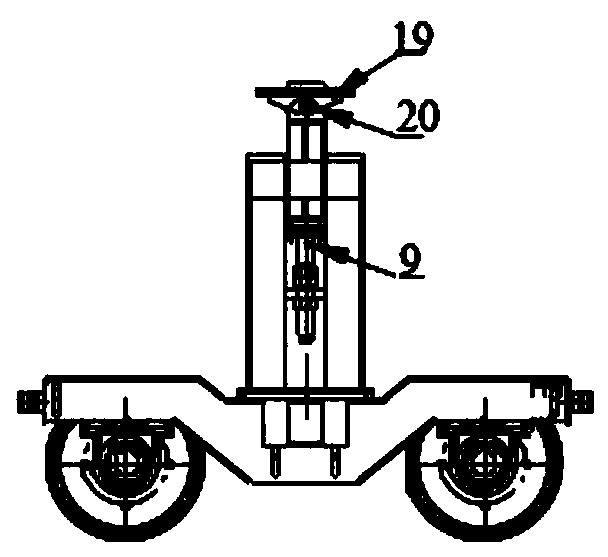

[0041] like Figure 1-16 As shown, the present embodiment provides a process bogie including an I-shaped frame 25, a support column 1, a height adjustment mechanism 9, an angle adjustment head 19 and a wheel set 33, and at least two groups are installed in parallel at the bottom of the I-shaped frame 25. The wheel set 33, the support column 1 is slidably installed on the upper surface of the I-shaped frame 25, and the sliding direction of the support column 1 is perpendicular to the installation direction of the wheel set 33, the height adjustment mechanism 9 is installed on the support column 1, and the angle adjustment head 19 It is rotatably mounted on the top of the height adjustment mechanism 9 .

[0042] In this embodiment, as Figures 4 to 6As shown, the support column 1 is connected by a group of square columns 2 through a group of connecting plates 3 groups of welding, the middle of the square column 2 is welded by a group of column support plates 4, the middle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com