Gear pump with asymmetric combined curved surface tooth form

An asymmetric, gear pump technology, applied in the direction of pumps, rotary piston pumps, rotary piston machines, etc., can solve the problems of local stress concentration, damage, pump cavity cleaning, etc., to eliminate stress concentration and improve pumping efficiency , The effect of smooth transmission

Inactive Publication Date: 2011-06-15

浙江凯斯特液压有限公司 +1

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This kind of hydraulic gear pump adopts the general undercutting technology on the non-working surface of the gear, which causes local stress concentration and is often damaged due to tooth collapse; , the high-pressure liquid on the outlet side of the gear pump pushes the gear to shift toward the low-pressure inlet side, causing the phenomenon of pump chamber sweeping

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

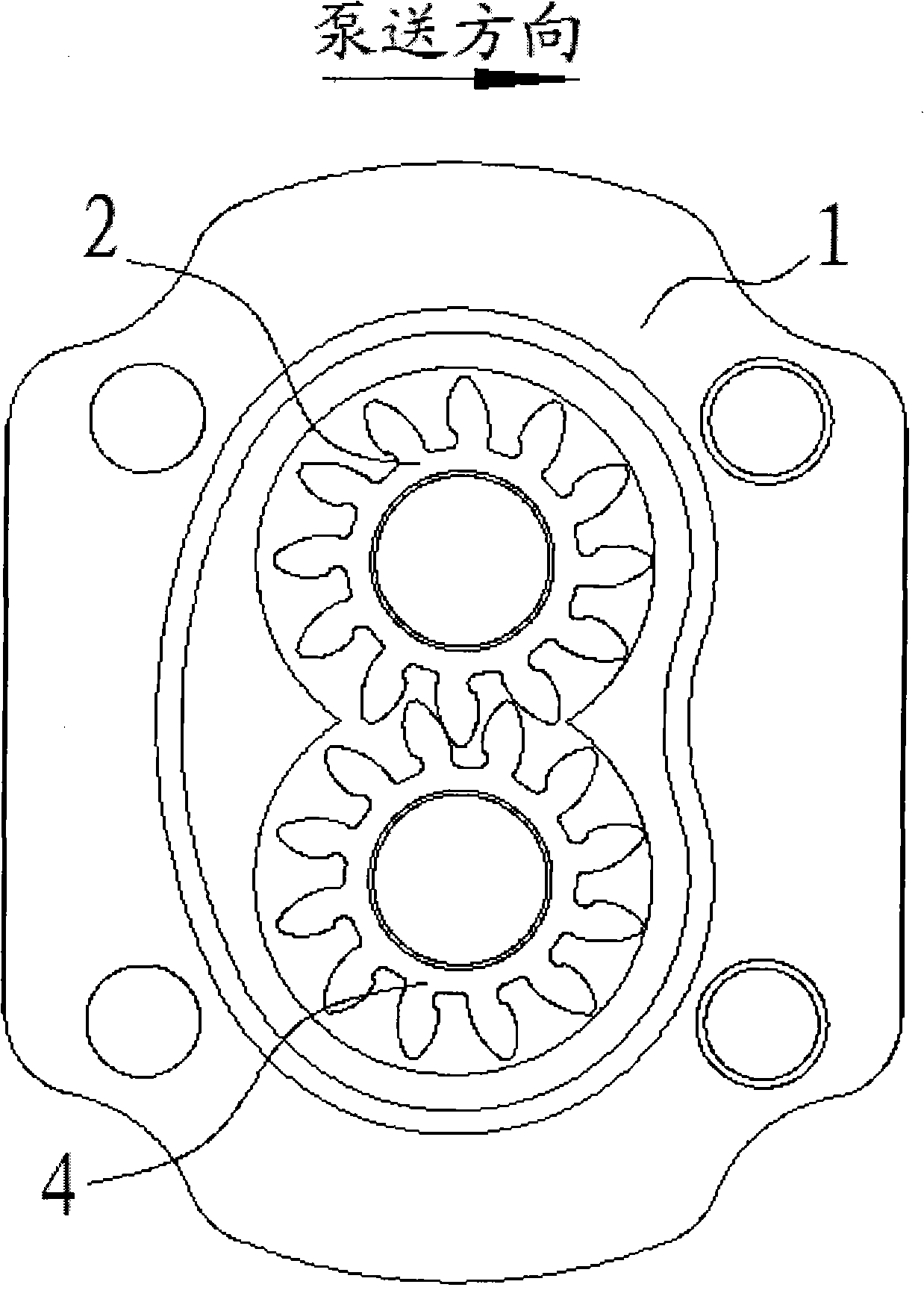

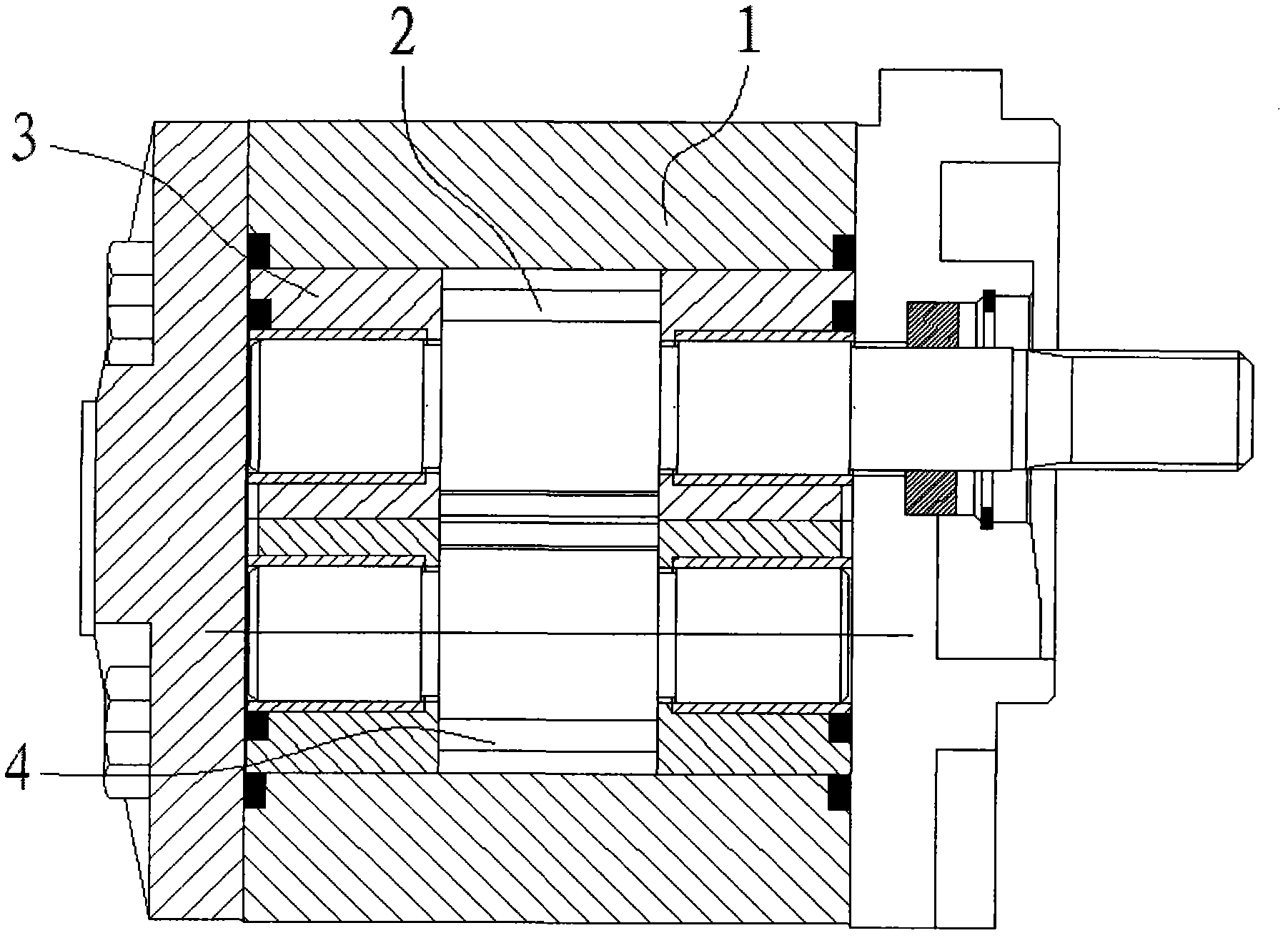

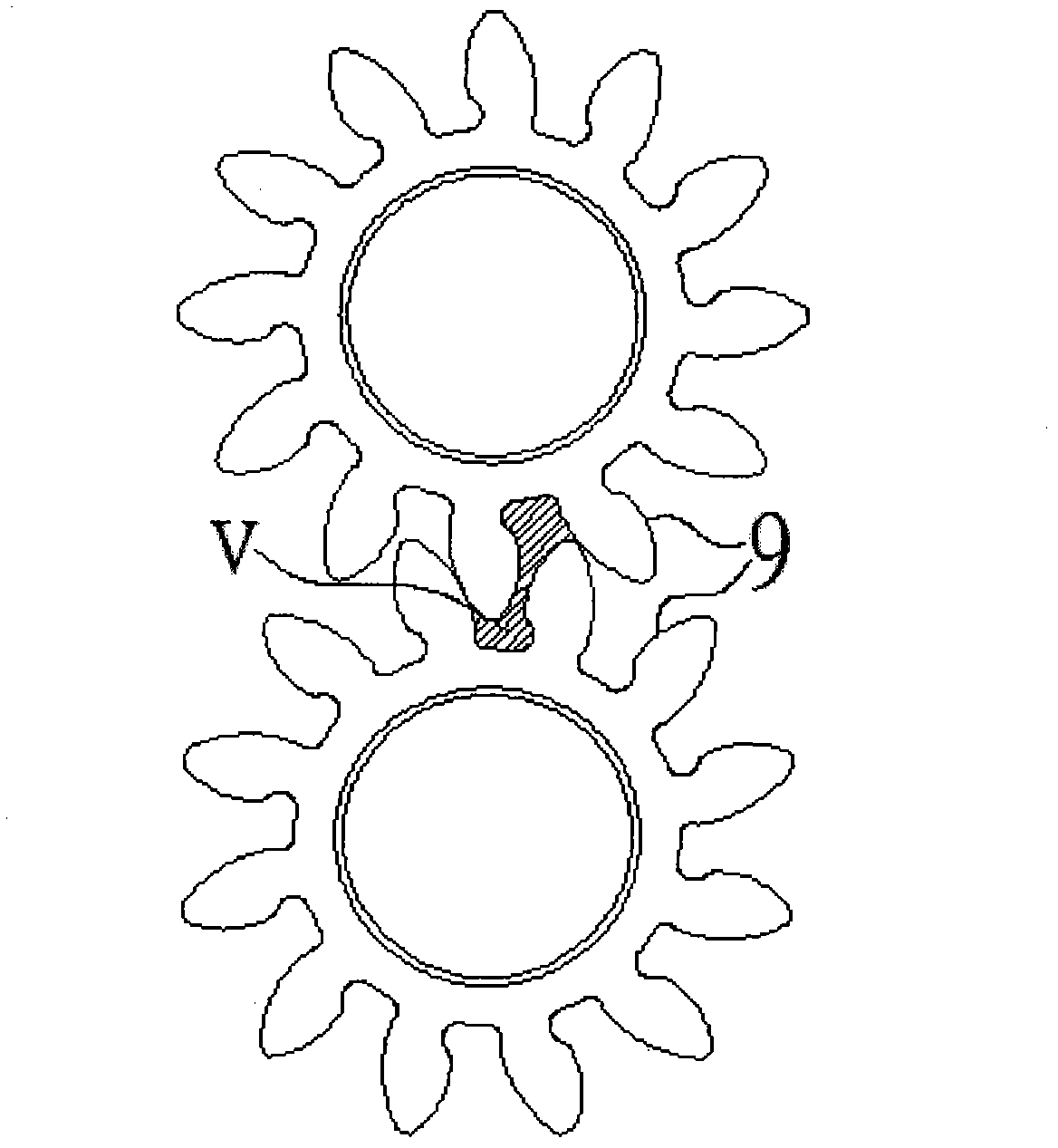

The invention discloses a gear pump with an asymmetric combined curved surface tooth form. The gear pump comprises a hollow pump body; a driving gear and a driven gear which are meshed mutually are arranged in the pump body; a tooth surface on one side where the driving gear and the driven gear are contacted and stressed is a working surface, and the tooth surface on the other side is a non-working surface; a pressure angle of the working surface is 20.5 to 22.8 degrees; the gear pump is characterized in that: a pressure angle of the non-working surface is 14 to 19 degrees; and the non-working surface is formed through smooth transition of an evolvent curved surface and a circular arc camber. The gear pump has large single pump output, a large overlap coefficient, small noise, low gear collapsing probability, and transmits stably, and the chamber sweeping phenomenon is avoided.

Description

Gear pumps with asymmetric compound surface tooth profiles technical field The invention relates to a pumping device, more specifically, the invention relates to a high-pressure gear pump with an asymmetrical tooth profile formed by an involute curved surface and an arc curved surface. Background technique The overlap coefficient of the gear refers to the logarithm of the gears that are meshed at the same time during the gear transmission process, that is to say, several teeth mesh together at the same time. A large overlap coefficient indicates that the transmission is more stable and the load on each tooth is smaller; the gear The pressure angle α refers to the acute angle between the common normal line of the two tooth profile curves and the common tangent line of the two pitch circles at the tangent point of the pitch circles of the two gears, also known as the meshing angle. The capacity is small; and the large pressure angle gear, the tooth strength of the gear is gr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04C2/18

Inventor 吴伟民

Owner 浙江凯斯特液压有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com