LNG (Liquefied Natural Gas) energy recovery process

A technology of energy recovery and process, applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of increasing BOG processing costs, high-grade energy loss, and large BOG volume, so as to save power consumption, effectively recover, and BOG The effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] LNG hydraulic turbine device (or other forms of expansion machinery) Take LNG hydraulic turbine device as an example:

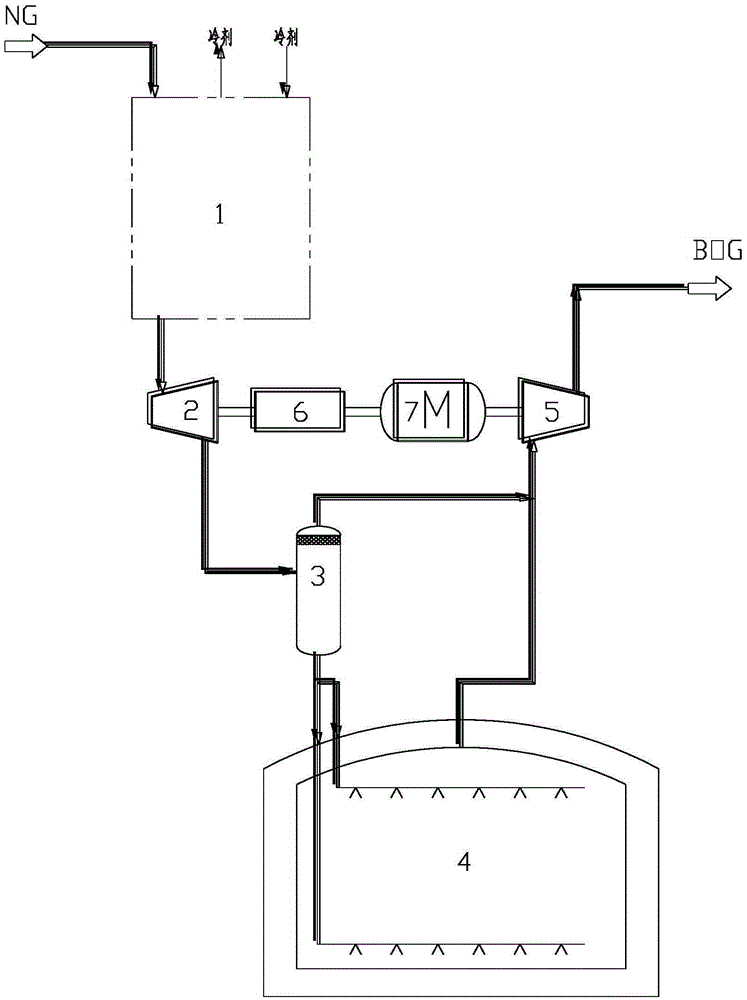

[0028] Such as figure 1 Shown is a schematic flow chart of an LNG energy recovery process, including:

[0029] The natural gas purified by the pretreatment device enters the cold box 1, exchanges heat with the refrigerant in the heat exchanger in the cold box, and is liquefied through pre-cooling and cryogenic processes to form high-pressure and low-temperature LNG. The LNG passes through the LNG hydraulic turbine device. The expansion end 2 decompresses, converts its own pressure energy into mechanical energy, and outputs low-temperature, low-pressure LNG; after the low-temperature, low-pressure LNG is separated from gas and liquid by the gas-liquid separation tank 3, the liquid-phase LNG is sent to the LNG storage tank 4 for storage, and the gas-phase LNG is sent to the LNG storage tank 4 for storage. The BOG merges with the BOG from the LNG storage...

Embodiment 2

[0035] The expansion end 2 of the LNG hydraulic turbine device is of axial flow type.

[0036] A driving mode switching device 6 is provided between the expansion end 2 of the LNG hydraulic turbine device and the motor 7, and the driving mode switching device 6 adopts a hydraulic coupling.

[0037] Other parts are set the same as in embodiment 1.

[0038] After a large number of tests, the process of the present invention can increase the LNG output by about 1% to 3% compared with the original LNG output (using the Joule-Thomson (J-T) valve).

Embodiment 3

[0040] The expansion end 2 of the LNG hydraulic turbine device is screw type.

[0041] A driving mode switching device 6 is provided between the expansion end 2 and the motor 7 of the LNG hydraulic turbine device, and the driving mode switching device 6 adopts an overrunning clutch.

[0042] Other parts are set the same as in embodiment 1.

[0043] After a large number of tests, the process of the present invention can increase the LNG output by about 1% to 3% compared with the original LNG output (using the Joule-Thomson (J-T) valve).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com