Pyrolysis gasification and purification method of household garbage

A technology of pyrolysis gasification and domestic waste, applied in chemical instruments and methods, chemical industry, biofuels, etc., can solve problems that hinder the rational use of combustible gases, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

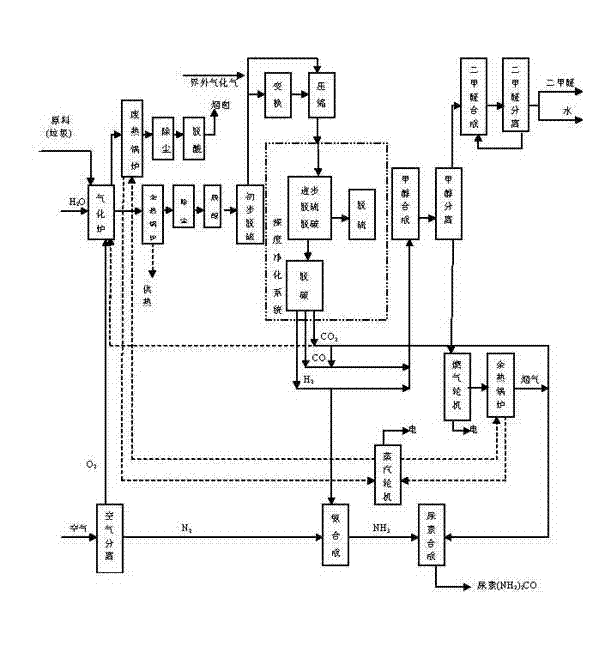

Image

Examples

Embodiment 1

[0045] A domestic waste pyrolysis gasification purification technology, comprising the following steps:

[0046] (1) Pyrolysis: Continuously put domestic waste containing about 10~30% water into the pyrolysis gasifier at a rate of 5 tons per hour (Chinese Patent No. ZL200610035185.5), under the condition of temperature 900°C and normal pressure , with 334Nm from the air separation unit 3 / h Oxygen undergoes combustion and cracking reactions, producing carbon monoxide (CO), carbon dioxide (CO 2 ), hydrogen (H 2 ), methane gas (CH 4 ), nitrogen (N 2 ) and inert gas argon (Ar) and a small amount of acidic impurities HCN, HCL, HF, H 2 S, COS and other combustible gases (that is, crude synthesis gas or biomass gas), and CO 2 , N 2 , Flue gas and slag of water vapor composition, the combustible gas and slag flow downward together, the flue gas flows upward, and the slag is discharged, the flue gas is cleaned and discharged into the chimney, and then the combustible gas is furt...

Embodiment 2

[0065] A domestic waste pyrolysis gasification purification technology, comprising the following steps:

[0066] (1) Pyrolysis: Continuously put domestic waste containing about 20-30% water into the pyrolysis gasifier at a rate of 25 tons per hour (Chinese Patent No. ZL200610035185.5), under the condition of temperature 1000°C and normal pressure , with 1670Nm from the air separation unit 3 / h Oxygen undergoes combustion and cracking reactions, producing carbon monoxide (CO), carbon dioxide (CO 2 ), hydrogen (H 2 ), methane gas (CH 4 ), nitrogen (N 2 ) and inert gas argon (Ar) and a small amount of acidic impurities HCN, HCL, HF, H 2 S, COS and other combustible gases (that is, crude synthesis gas or biomass gas), and CO 2 , N 2 , Flue gas and slag of water vapor composition, the combustible gas and slag flow downward together, the flue gas flows upward, and the slag is discharged, the flue gas is cleaned and discharged into the chimney, and then the combustible gas is f...

Embodiment 3

[0085] A domestic waste pyrolysis gasification purification technology, comprising the following steps:

[0086] (1) Pyrolysis: Continuously put domestic waste containing about 20-50% water into the pyrolysis gasifier at a rate of 50 tons per hour (Chinese Patent No. ZL200610035185.5), under the condition of temperature 1000°C and normal pressure , with 3340Nm from the air separation unit 3 / h Oxygen undergoes combustion and cracking reactions, producing carbon monoxide (CO), carbon dioxide (CO 2 ), hydrogen (H 2 ), methane (CH 4 ), nitrogen (N 2 ) and inert gas argon (Ar) and a small amount of acidic impurities HCN, HCL, HF, H 2 S, COS and other combustible gases (that is, crude synthesis gas or biomass gas), and CO 2 , N 2 , Flue gas and slag of water vapor composition, the combustible gas and slag flow downward together, the flue gas flows upward, and the slag is discharged, the flue gas is cleaned and discharged into the chimney, and then the combustible gas is furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com