Slurrying method of organic dangerous solid waste

A hazardous solid and waste technology, which is applied in the pulping field of organic hazardous solid waste, can solve problems such as missing, and achieve the effect of resourceful and harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

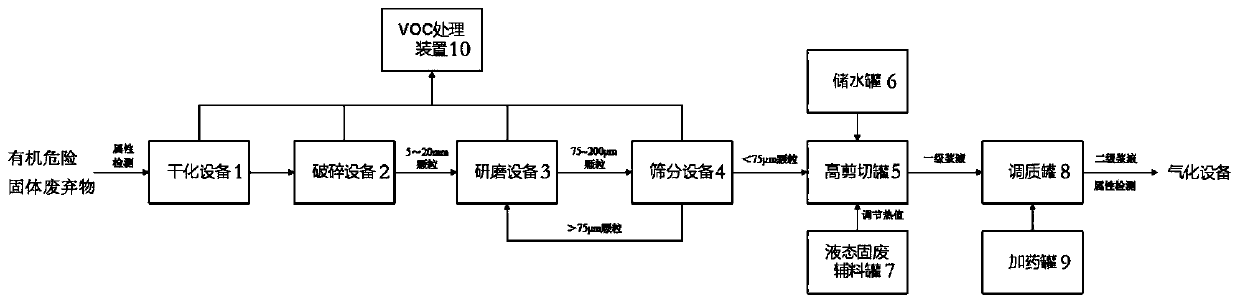

[0032] Such as figure 1 Shown, the object of the present invention is achieved by the following technical measures: a pulping method of organic hazardous solid waste, comprising the following steps,

[0033] 1) Detect and classify organic hazardous solid materials;

[0034] 2) Transport the classified organic hazardous solid materials to the drying equipment 1 for drying; the drying temperature will be adjusted according to the different temperatures of the organic hazardous solid materials.

[0035] 3) The organic hazardous solid material after the drying treatment can be transported to the crushing equipment 2 through the conveyor belt for crushing treatment;

[0036] 4) The organic hazardous solid material is processed by the crushing equipment 2, and the particle size is reduced, and then sent to the grinding equipment 3;

[0037] 5) Use the grinding equipment 3 to grind the organic hazardous solid material, and transport it to the screening equipment 4;

[0038] 6) Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com