Color sand and production thereof

A technology of colored sand and wrapping, applied in the direction of coating, etc., can solve the problems of high requirements and high production costs, and achieve the effect of solving poor aging resistance, avoiding cumbersomeness, and expanding the range of choices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

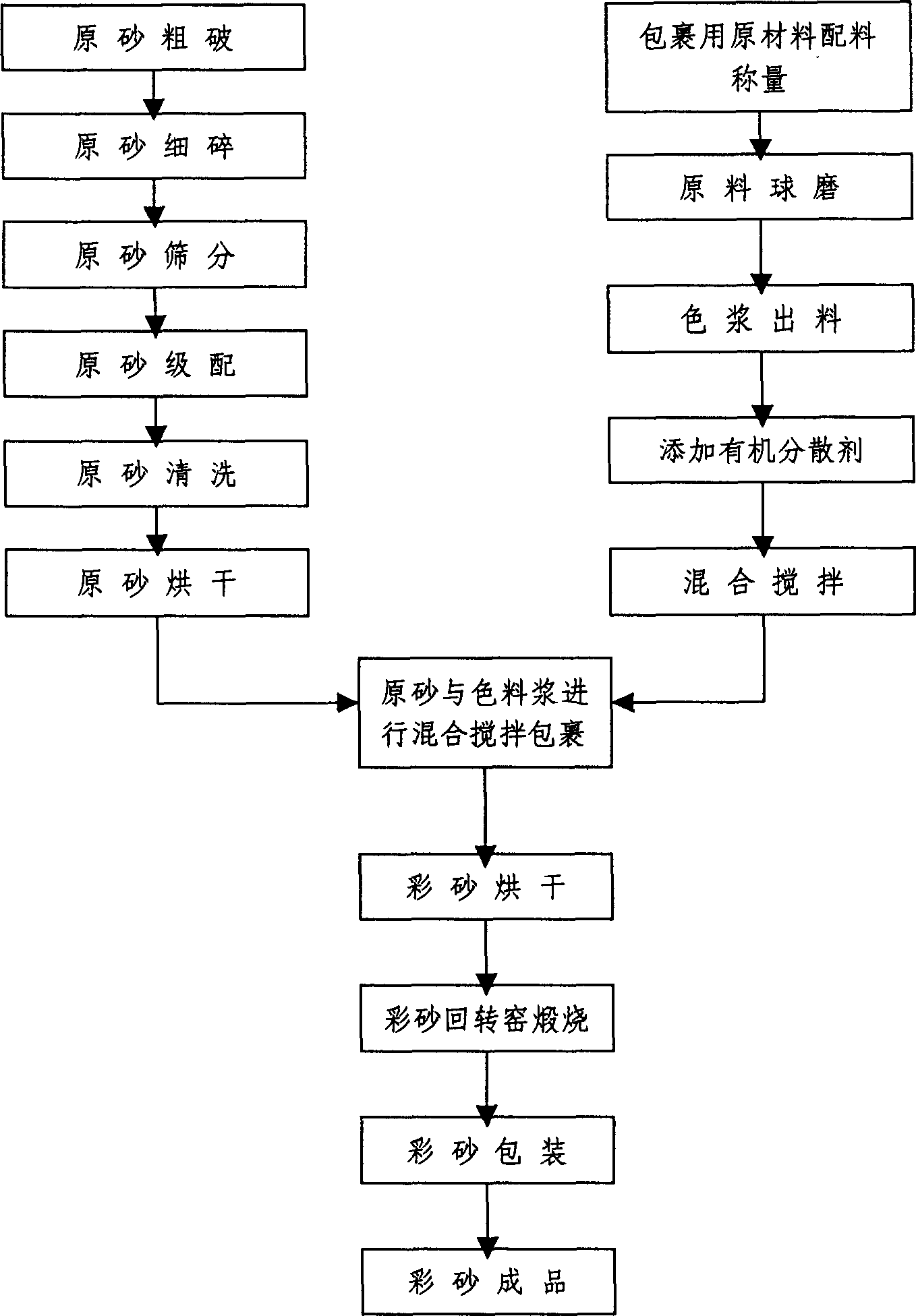

Method used

Image

Examples

example 1

[0047] 1.1 Preparation of colored sand base material

[0048] The selected basalt minerals are crushed by a jaw crusher, then crushed by a cone crusher, and then screened, washed and dried to prepare particles with a certain size distribution. The Chinese sieve is the standard sieve for testing. .

[0049] 8-12 mesh 2%

[0050] 12-16 mesh 25%

[0051] 16-20 mesh 18%

[0052] 20-30 mesh 40%

[0053] 30-40 mesh 10%

[0054] 5% below 40 mesh.

[0055] 1.2 Preparation of opacified frit

[0056] Carry out batching according to following formula composition, by weight percentage:

[0057] Soda Ash 20%,

[0058] Feldspar 12%,

[0059] Limestone 5%,

[0061] Washed Kaolin 2.5%,

[0062] Quartz 20%,

[0063] Boric acid 24.4%,

[0064] Zirconia 8.1%,

[0065] Fluorspar 1.5%.

[0066] Then it is melted at 1200°C, quenched into...

example 2

[0082] 2.1 Preparation of colored sand base material

[0083] The iron ore waste residue is selected to be crushed by a jaw crusher, then crushed by a cone crusher, and then sieved, washed and dried to prepare particles with a certain particle size distribution. The Chinese mesh is the standard sieve for testing. head. The particle size distribution is the same as Example 1.

[0084] 2.2 Preparation of opacified frit

[0085] Carry out batching according to following formula composition, by weight percentage:

[0086] Soda Ash 17%,

[0087] Feldspar 13%,

[0088] Limestone 7%,

[0090] Washed Kaolin 1.5%,

[0091] Quartz 21.5%,

[0092] Boric acid 26%,

[0093] Zirconia 5%,

[0094] Fluorite 1%.

[0095] Then it is melted at 1250°C, quenched into granules, and ball milled to 325 mesh for later use.

[0096] 2.3 Preparation of color pas...

example 3

[0111] 3.1 Preparation of colored sand base material

[0112] The quartz rock is selected to be crushed by a jaw crusher, then crushed by a cone crusher, and then screened, washed and dried to prepare particles with a certain particle size distribution. The Chinese mesh is the standard mesh for testing. . The particle size distribution is the same as Example 1.

[0113] 3.2 Preparation of opacified frit

[0114] Carry out batching according to following formula composition, by weight percentage:

[0115] Soda Ash 25%,

[0116] Feldspar 10%,

[0117] Limestone 7%,

[0119] Washed Kaolin 6%,

[0120] Quartz 18%,

[0121] Boric acid 22%,

[0122]Zirconia 2%,

[0123] Fluorite 2%.

[0124] Then it is melted at 1200°C, quenched into granules, and ball milled to 325 mesh for later use.

[0125] 3.3 Preparation of color paste for surface wrapping of colo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com