Baby suite prepared from ecological organic colored cotton

An organic and colored cotton technology, applied in the field of textile processing, can solve the problems of unstable color, poor fiber fastness, high moisture regain, etc., and achieve the effect of improving color fastness, enhancing color fastness, and reducing discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

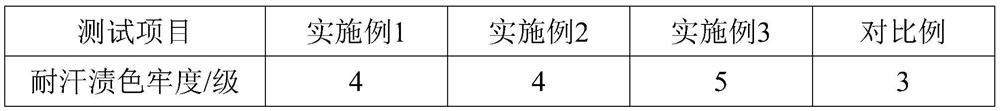

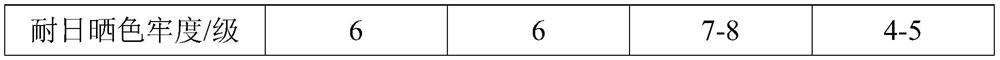

Embodiment 1

[0027] (1) Preparation of aqueous color fastness enhancer solution: add deionized water to polyvinyl alcohol 17-88, heat to reflux state, stir and dissolve, and prepare a color fastness enhancer aqueous solution with a mass concentration of 12%.

[0028] (2) Processing of color-fast organic colored cotton yarn: the organic colored cotton yarn is obtained by immersing the organic colored cotton yarn in an aqueous solution of a color fastness enhancer at 55°C for 2 hours, then rolling off excess solution and drying at 75°C.

[0029] (3) Processing of organic colored cotton fabric: the fabric is woven with color-fast organic colored cotton yarn, with a warp density of 520 threads / 10cm and a weft density of 450 threads / 10cm.

Embodiment 2

[0031] (1) Preparation of color fastness enhancer aqueous solution: add deionized water to polyvinyl alcohol 50-88, heat to reflux state, stir and dissolve, and prepare a color fastness enhancer aqueous solution with a mass concentration of 12%.

[0032] (2) Processing of color-fast organic colored cotton yarn: the organic colored cotton yarn is obtained by immersing the organic colored cotton yarn in an aqueous solution of a color fastness enhancer at 55°C for 1 hour, then rolling off excess solution and drying at 75°C.

[0033] (3) Processing of organic colored cotton fabric: the fabric is woven with color-fast organic colored cotton yarn, with a warp density of 520 threads / 10cm and a weft density of 450 threads / 10cm.

Embodiment 3

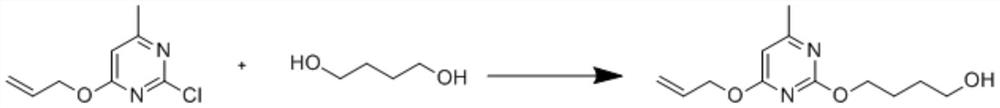

[0035] Preparation of 4-((4-(allyloxy)-6-methylpyrimidin-2-yl)oxy)-1-butanol: Add 0.1mol 4-(allyloxy)-2- Chloro-6-methylpyrimidine and 0.1mol 1,4-butanediol, and 0.1mol triethylamine was added dropwise, heated to 60°C and then kept for 3h reaction, after the reaction was completed, deionized water was added dropwise under stirring, until there was no new Stop adding water after the precipitate is formed, let it stand for 10 minutes, filter, wash with water, and dry the precipitate at 80°C. 1 H NMR (DMSO-d6, 400MHz), δ: 6.05(m, 1H), 5.94(s, 1H), 5.43(d, 1H), 5.29(d, 1H), 4.92(d, 2H), 4.56(s ,1H), 4.03(t,2H), 3.63(t,2H), 2.42(s,3H), 1.89(m,2H), 1.60(m,2H).ESI-MS: m / z=239.13[M +1] + .

[0036] The polyvinyl alcohol 17-88 in Example 1 is replaced by the 4-((4-(allyloxy)-6-methylpyrimidin-2-yl)oxy)- 1-butanol and azobisisobutylimidazoline hydrochloride, other conditions unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com