Method for preparing molecular sieve catalyst used in carbon 4 liquid gas aromatization reaction

A liquefied gas, aromatization technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of carbon deposition, catalyst stability limitation, etc., and achieve the effect of high aromatization reaction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

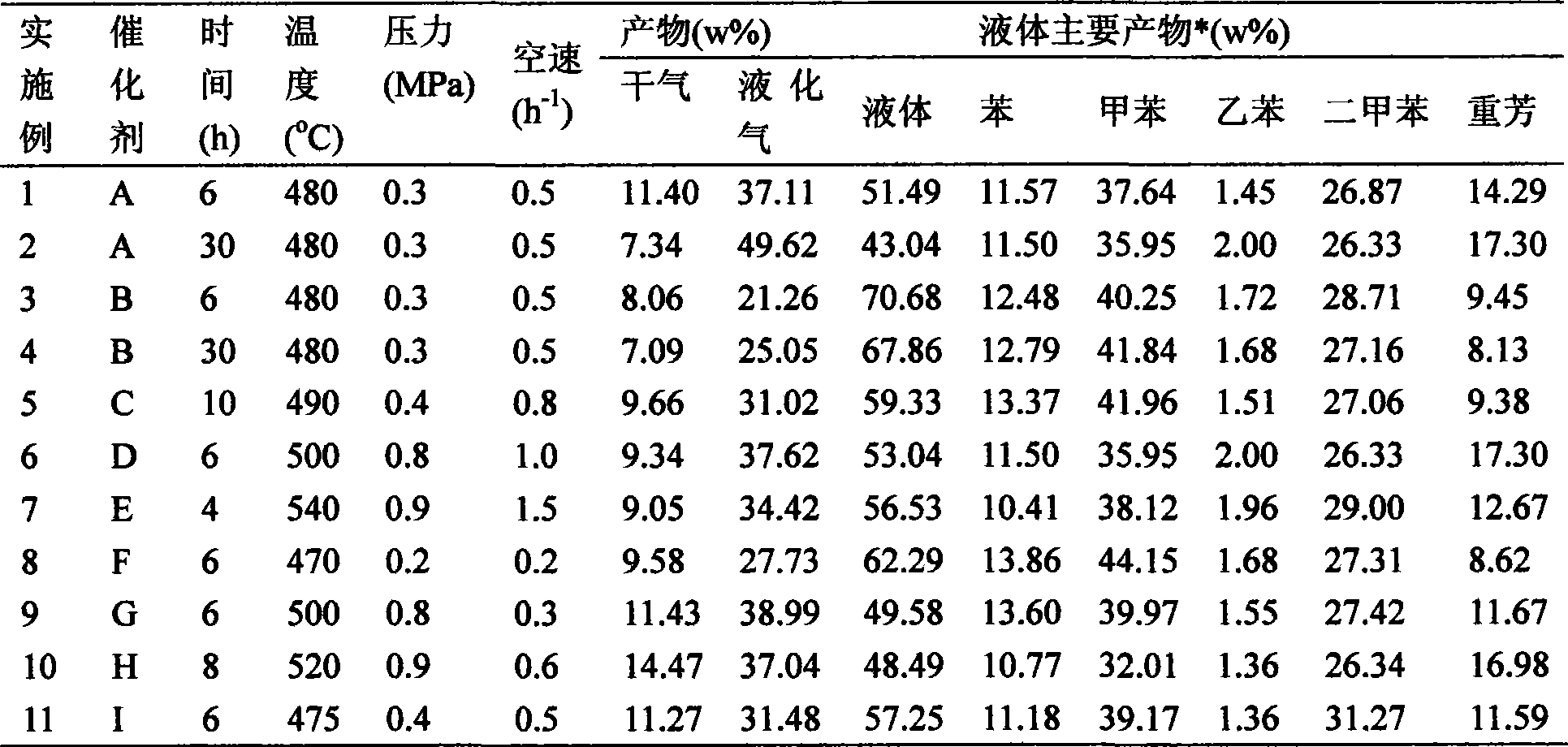

Examples

Embodiment 1

[0031] A certain amount of rare earth-70 wt% ZSM5 / 30 wt% ZSM11 co-crystallized molecular sieve (rare earth content accounts for 1.2 wt% of rare earth-70 wt% ZSM5 / 30 wt% ZSM11 co-crystallized molecular sieve), alumina and deionized water are mixed evenly Finally, extrusion molding, drying, 550 ° C roasting for 4 hours. 20g of the obtained roasted product was placed in 200ml, 0.2M NaOH solution, stirred in a constant temperature water bath at 75°C with air bubbling for 2h, cooled to room temperature, filtered, washed until neutral, and then washed with 0.8mol / L nitric acid at 80°C The ammonium solution was exchanged 3 times, washed 2 times, dried at 120°C, calcined at 540°C for 3 hours to obtain H-type molecular sieve, and then treated with water vapor at 550°C for 3 hours, and zinc metal was loaded by impregnation method, using ZnCl 2 The solution was soaked at room temperature for 12 hours, dried at 120°C, and calcined at 580°C for 3 hours. The resulting catalyst had a Zn load...

Embodiment 2

[0033] A certain amount of rare earth-50 wt% ZSM5 / 50 wt% ZSM11 co-crystallized molecular sieve (rare earth content accounts for 5.2 wt% of rare earth-50 wt% ZSM5 / 50 wt% ZSM11 co-crystallized molecular sieve), aluminum oxide and deionized water are mixed evenly Finally, extrude into strips, dry, and bake at 530°C for 8 hours. 20 g of the obtained roasted product was placed in 200 ml of 0.8 M KOH solution, and after alkali treatment temperature was 55 ° C, air bubbled and stirred for 9 h, then cooled to room temperature, filtered, washed until neutral, and used at 80 ° C with 0.8 mol / L The ammonium nitrate solution was exchanged 3 times, washed 2 times, dried at 120°C, calcined at 540°C for 3 hours to obtain H-type catalyst, and then treated with water vapor at 450°C for 8 hours, zinc metal was loaded by impregnation method, and Zn(NO 3 ) 2 The solution was soaked at room temperature for 12 hours, dried at 120°C, and calcined at 600°C for 2 hours. The resulting catalyst had a Z...

Embodiment 3

[0035] A certain amount of rare earth-10 wt% ZSM5 / 90 wt% ZSM11 co-crystallized molecular sieve (rare earth content accounts for 4.2 wt% of rare earth-10 wt% ZSM5 / 90 wt% ZSM11 co-crystallized molecular sieve), alumina and deionized water are mixed evenly Afterwards, extrusion molding, drying and calcination at 550°C for 4 hours. 20 g of the obtained calcined product was placed in 200 ml of 0.5 M NaOH solution, and after alkali treatment temperature was 65 ° C, air bubbled and stirred for 2 h, then cooled to room temperature, filtered, washed until neutral, and used at 80 ° C with 0.8 mol / L The ammonium nitrate solution was exchanged 3 times, washed 2 times with water, dried at 120°C, and calcined at 540°C for 3 hours to obtain an H-type catalyst, and then impregnated to support zinc metal, using Zn(NO 3 ) 2 solution, dried at 120°C, calcined at 580°C for 3 hours, and treated with water vapor at 600°C for 3 hours, the resulting catalyst had a Zn loading of 2 wt%, which was desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com