Cleaning antirust agent, preparation method and method for removing scale and preventing rust by using cleaning antirust agent

A technology of antirust agent and corrosion inhibitor, which is applied in the fields of cleaning antirust agent, cleaning antirust agent descaling and antirust, cleaning antirust agent, and can solve problems such as poor cleaning effect and metal rust of the water tank body , to achieve the effect of improving anti-corrosion ability, improving anti-rust ability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of cleaning antirust agent of the present invention, this method comprises the following steps:

[0036] Add metered deionized water into the reaction kettle; first add citric acid, ammonium nitrate, ethylenediamine tetraacetate under stirring, then add solubilizer, scale inhibitor dispersant, corrosion inhibitor and penetrating agent to make it fully Dissolve; adjust the pH value with citric acid or ammonia water, filter, take samples for inspection, and repackage after passing the test.

[0037] The present invention uses the method for descaling and antirust of described cleaning antirust agent, and this method comprises the following steps:

[0038] Add the cleaning antirust agent into the antifreeze coolant of the water tank of the motor vehicle. After the vehicle is idling for a predetermined time, open the drain valve of the water tank to discharge the cleaning antirust agent, and add new antifreeze coolant into the water tank.

Embodiment 1

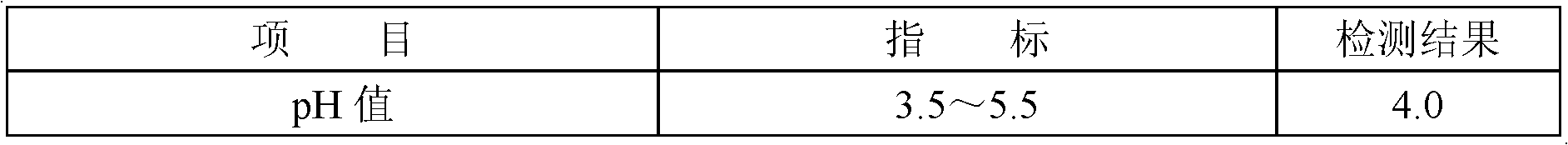

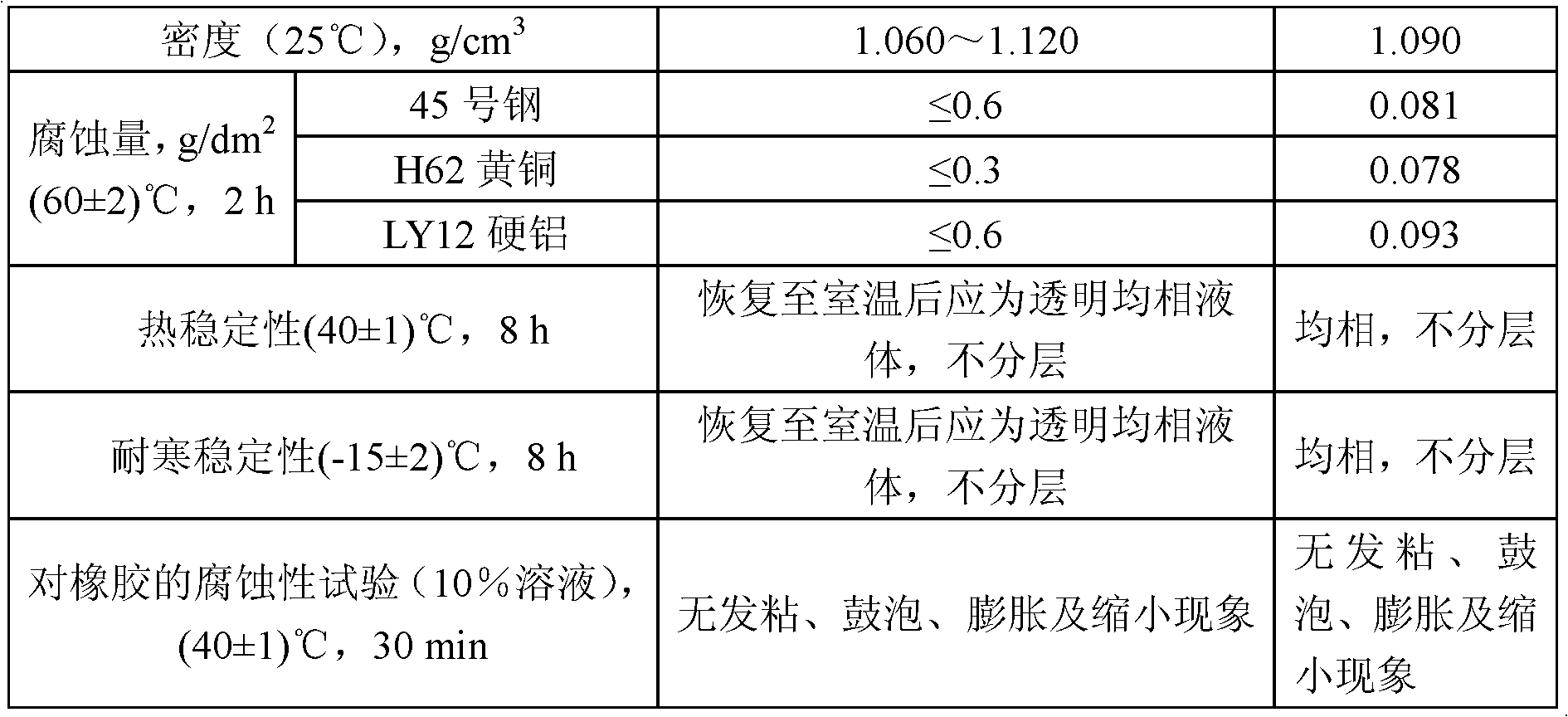

[0040] Add metered 69g deionized water in the batching reactor, under stirring action, add 10% citric acid (10g), 5% ammonium nitrate (5g), 3% edetate disodium (3g), 5% % ethylene glycol monobutyl ether (5g), 2% acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer (AA / AMPS) (2g) and 1% benzotriazole (1g), 2% % hexamethylenetetramine (2g), then add 1% polyaniline nano-dispersion (1g), 2% sodium diisooctyl succinate sulfonate (2g), high-speed stirring made it fully dissolve in 20~30 minutes, finally Adjust the pH value to 3.5-4.5 with citric acid or ammonia water, filter, take samples for inspection, and pack.

Embodiment 2

[0042] Add metered deionized water into the batching reaction kettle, and add 10% citric acid, 4% ammonium nitrate, 4% disodium edetate, 5% ethylene glycol monoethyl ether, 3% hydrolyzed horse To acid anhydride (HPMA), then add 1% lan826 corrosion inhibitor, 0.5% polyaniline nano-dispersion, 3% polyether modified polydimethylsiloxane, stir at high speed for 20-30 minutes to fully dissolve, and finally use Adjust the pH value to 3.5-4.5 with citric acid or ammonia water, filter, take samples for inspection, and repackage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com