High impact polymer interlayers

a polymer interlayer and high impact resistance technology, applied in the direction of synthetic resin layered products, transportation and packaging, chemistry apparatus and processes, etc., can solve the problems of low penetration resistance, low impact resistance of interlayer, and inability to resist high wind load after impact, so as to achieve high impact protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

Impact Resistance:

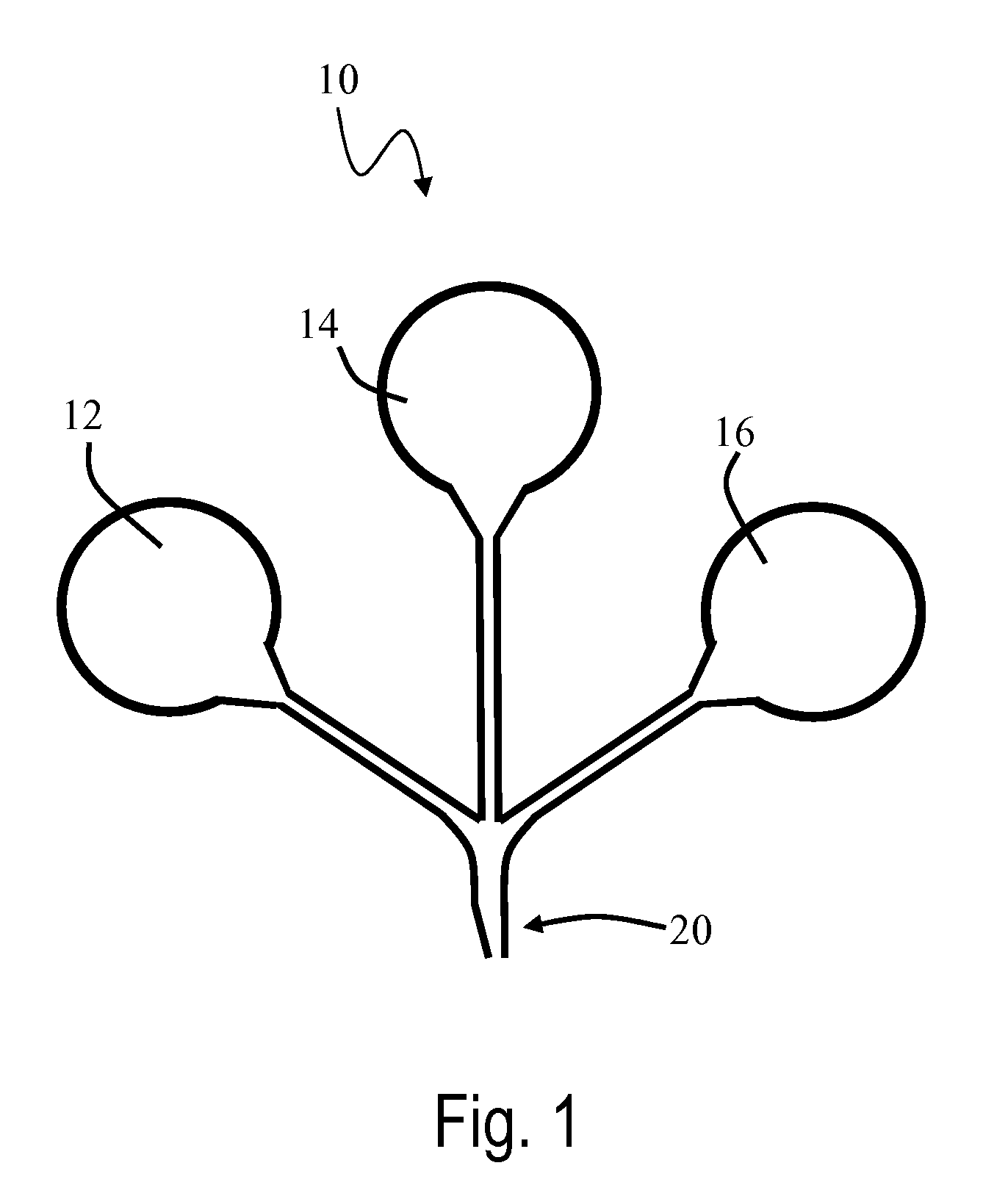

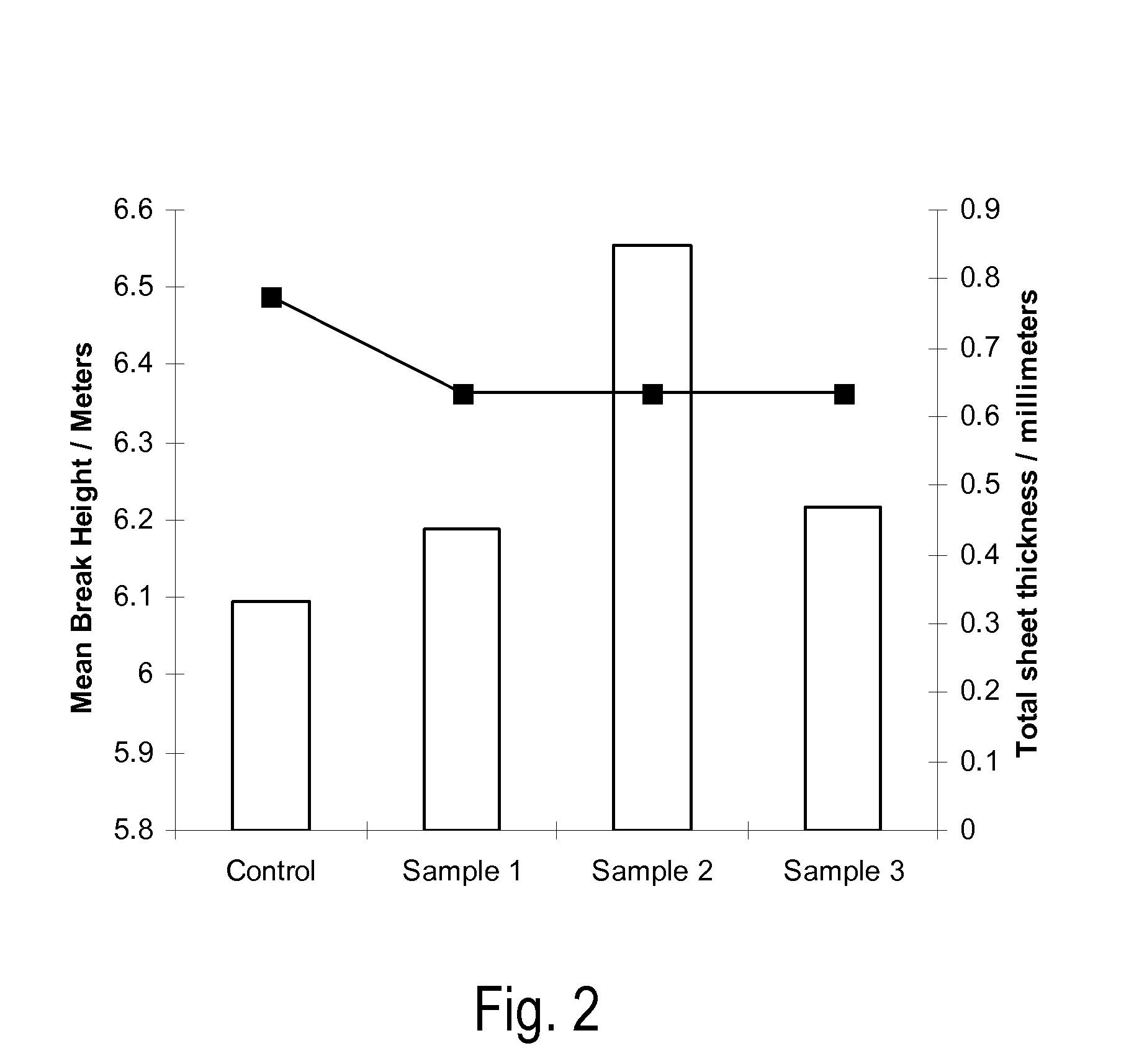

[0065]Examples of the poly(vinyl butyral) multiple layer interlayers having improved impact resistance are listed in Table 1. The impact resistance, shown as the Mean Break Height (MBH) in the unit of meters, is illustrated in FIG. 2.

[0066]For the three Samples given in Table 1, each sample interlayer has a total thickness of 0.64 millimeters (25 mil) comprising a first layer and a third layer each having 16% residual hydroxyl content and a thickness of 0.10 millimeters (4 mils) with a second layer having 18.5% residual hydroxyl content and a thickness of 0.43 millimeters (17 mils) between and in contact with the first layer and the third layer.

[0067]Table 1 provides the phr of the plasticizer triethylene glycol di-(2-ethylhexanoate) (3GEH) formulated with the resin.

TABLE 1phr of plasticizerSampleLayer 1Layer 2Layer 3132223222522253322732

[0068]As shown in FIG. 2, the tested multiple layer interlayer embodiments of the present invention demonstrate a higher impact p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com