Solar cell module back veneer material

A solar cell and backplane technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of high cost and low reflectivity, and achieve the effects of increased power, good light reflectivity, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

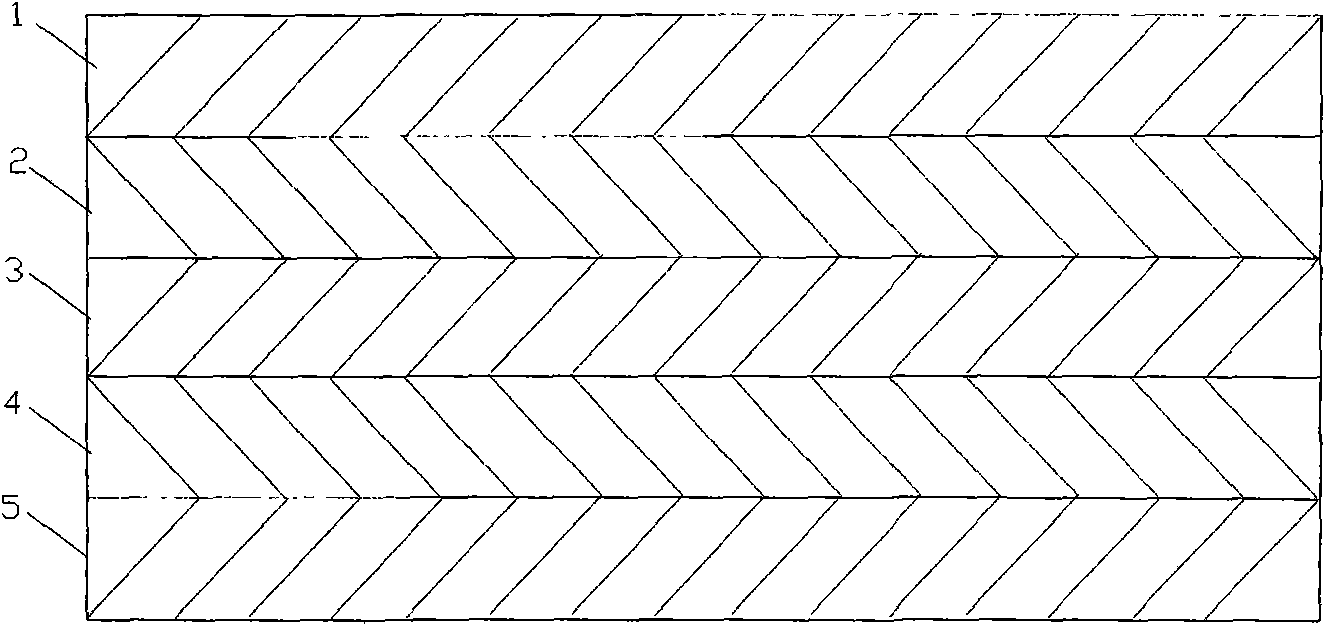

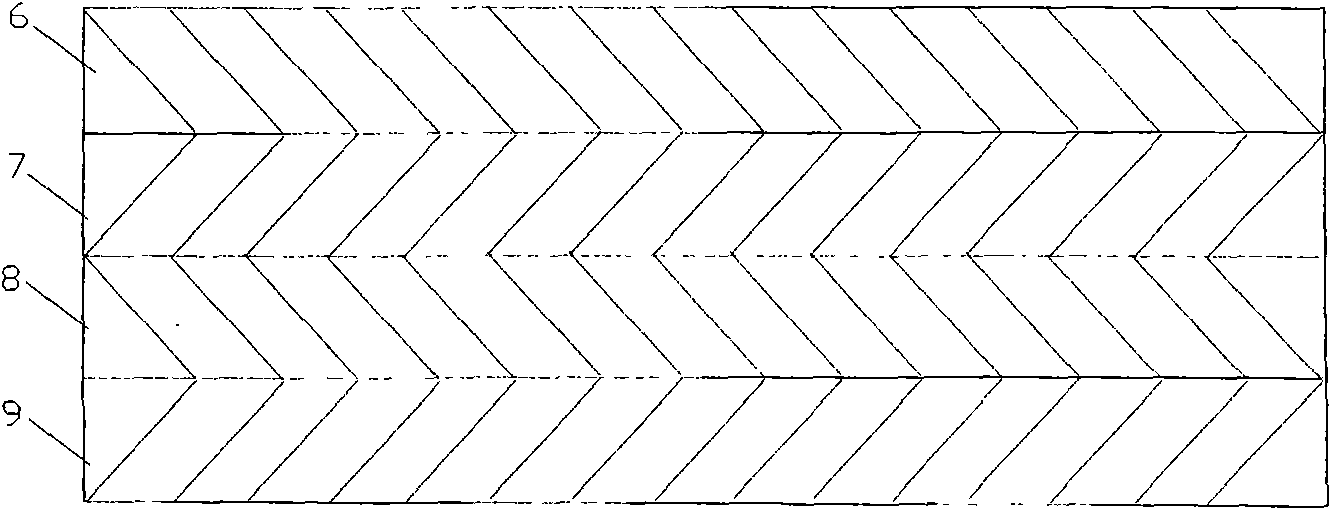

Image

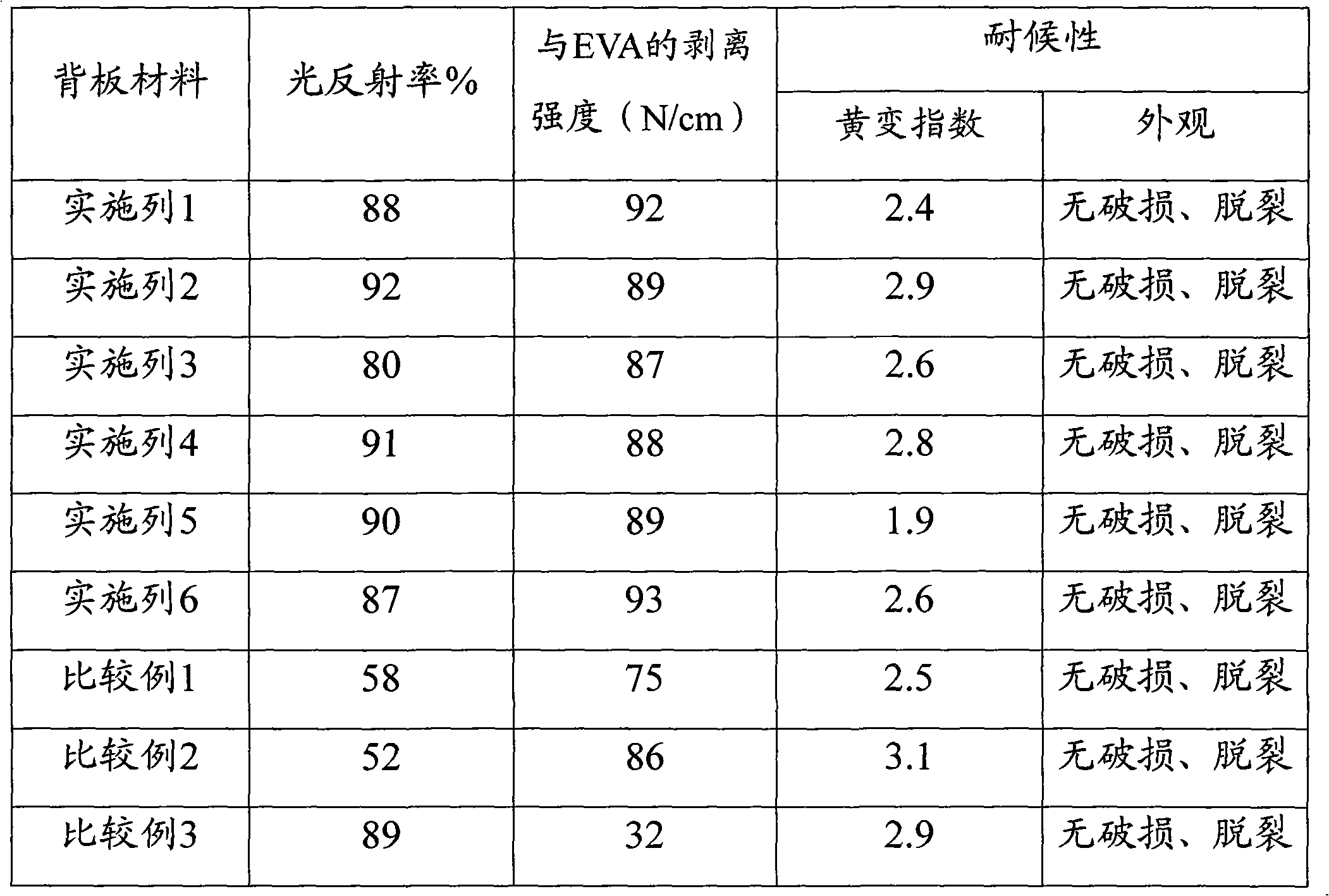

Examples

Embodiment 2

[0068] The method of making the backsheet and the materials used are the same as in Example 1, except that the fluorine-containing resin coating liquid A is replaced by the fluorine-containing resin coating liquid B, and the coating method, drying and film formation, surface treatment, slitting, and coiling processes are carried out in the same manner. example 1.

Embodiment 3

[0070] The method of making the backsheet and the materials used are the same as in Example 1, except that the fluorine-containing resin coating liquid A is replaced by the fluorine-containing resin coating liquid C, and the coating method, drying and film formation, surface treatment, slitting, and coiling processes are carried out in the same manner. example 1.

Embodiment 4

[0072] The manufacturing method and materials used for the backsheet are the same as in Example 1, except that the primer A is replaced by the primer B, and the coating method, drying and film formation, surface treatment, slitting, and winding processes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com