Method for recovering cobalt, nickel and manganese from waste lithium cells

A technology for waste lithium batteries and lithium-ion batteries, which is applied in the field of nickel and manganese and cobalt recovery, can solve problems such as inability to guarantee product quality, incomplete dealumination and complex processes, etc., and achieve significant environmental benefits, low consumption of auxiliary materials, and high-quality products. The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

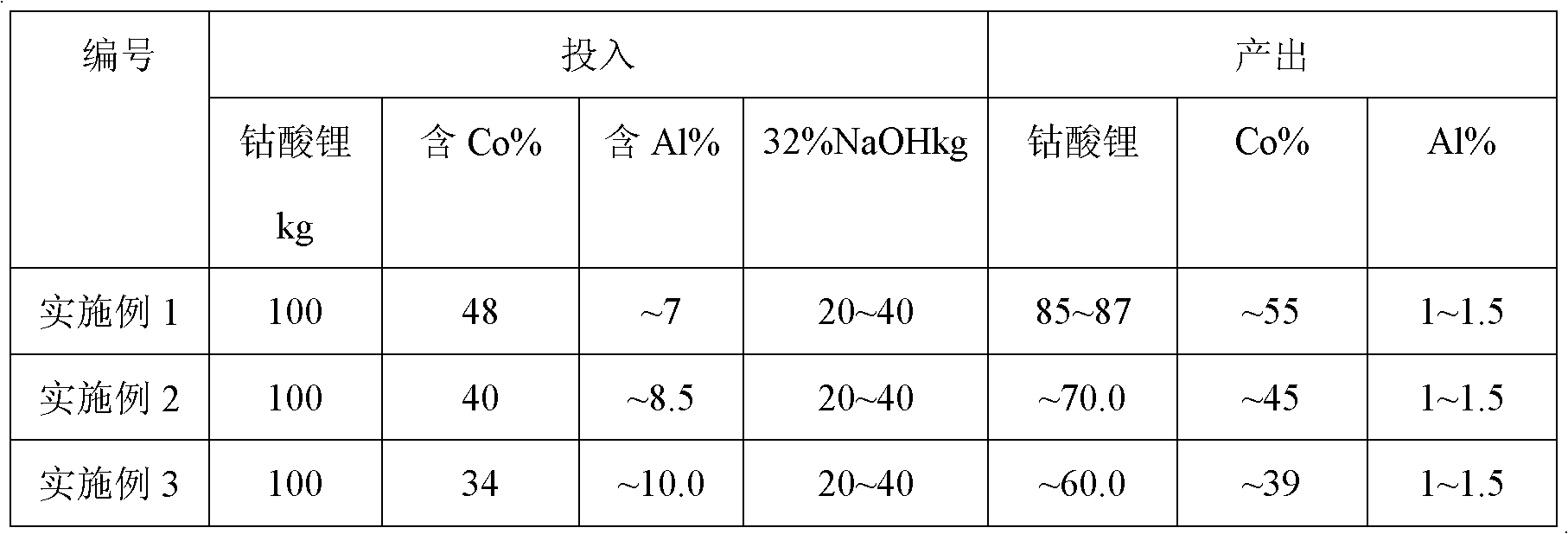

Embodiment 1-3

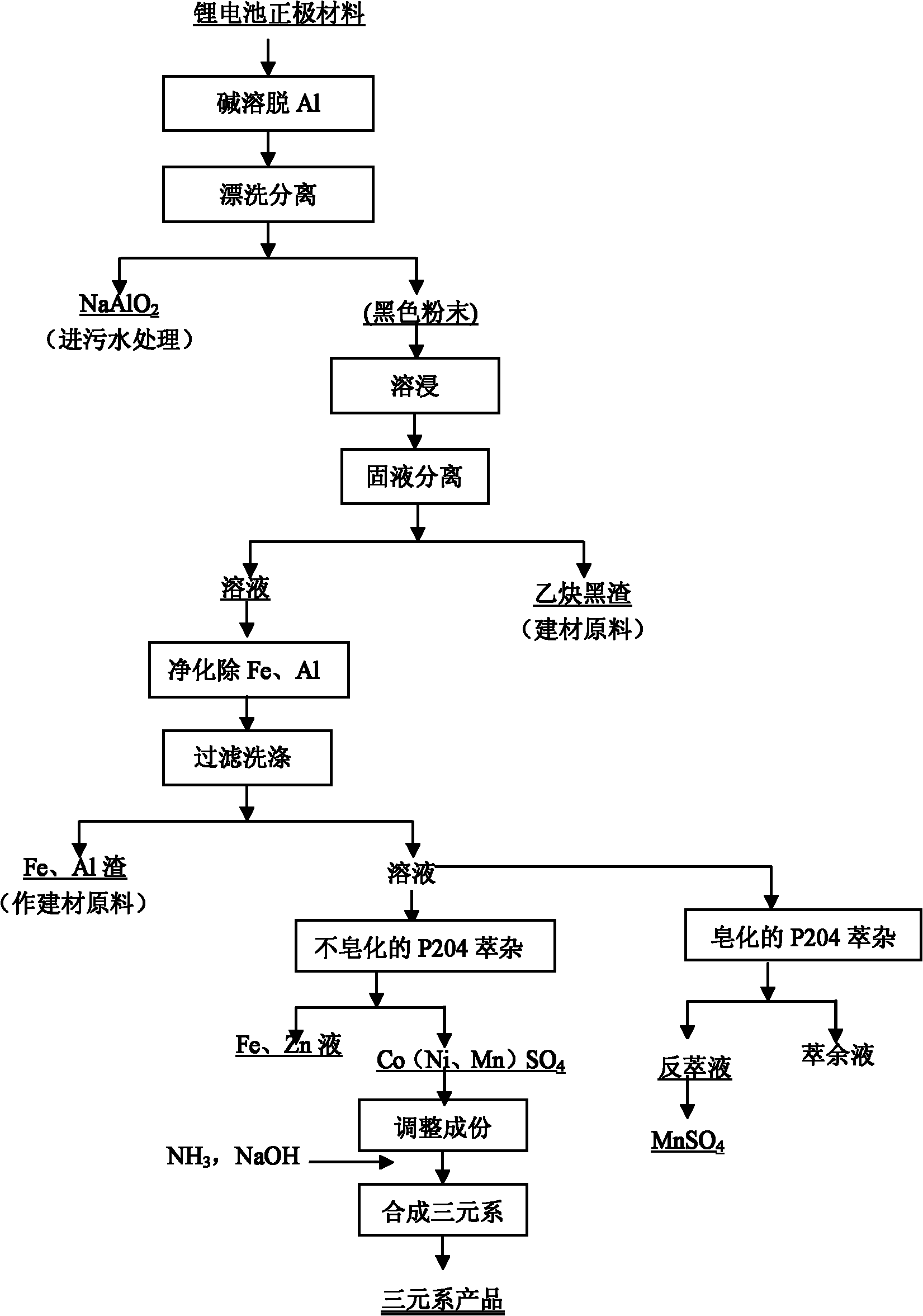

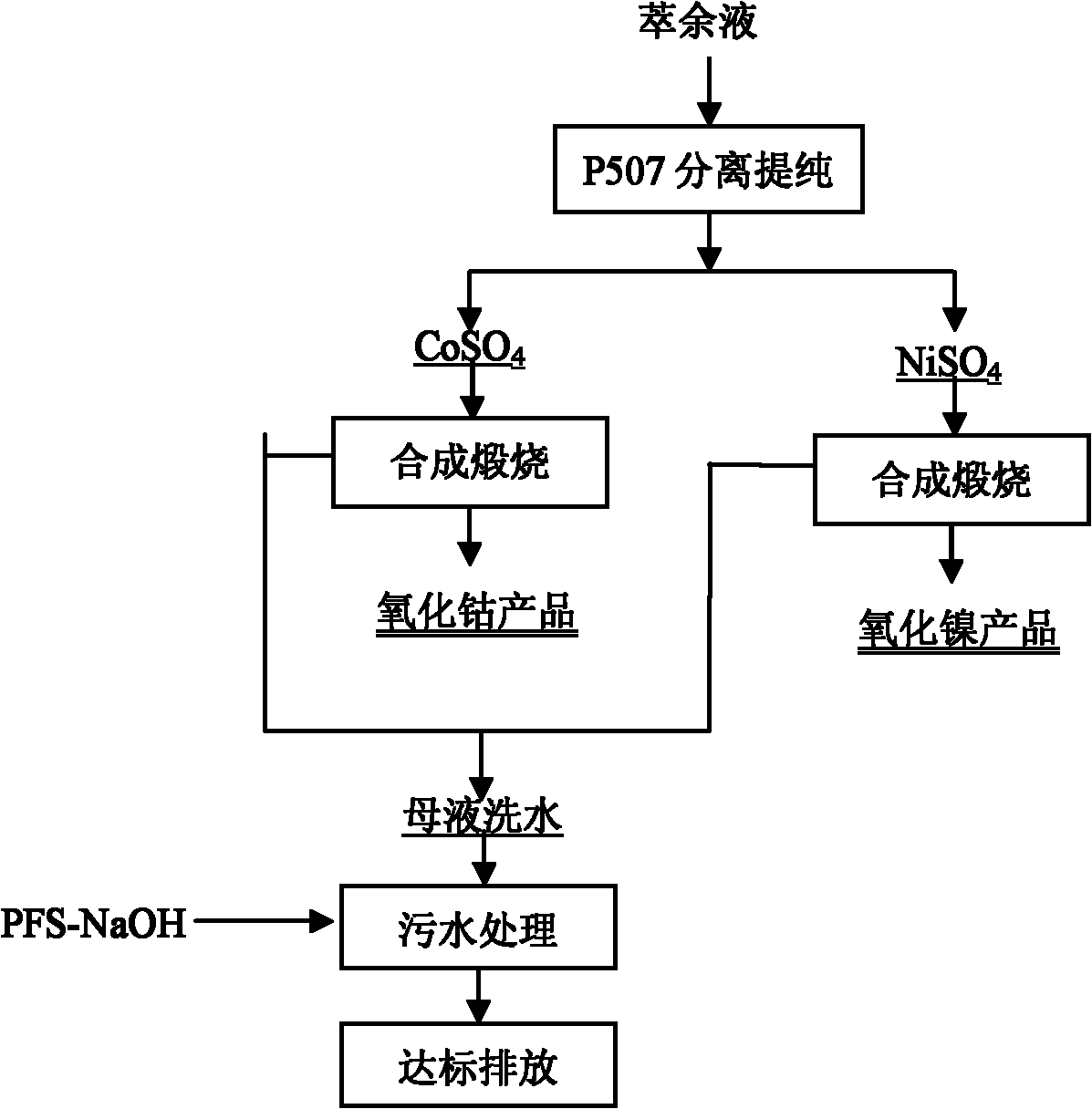

[0021] The present invention treats lithium cobalt oxide as positive electrode material (containing a small amount of manganese and nickel elements), and the specific steps are as follows:

[0022] 1) dismantling and sorting the waste lithium-ion battery after discharging to obtain a positive electrode material containing lithium cobaltate, and then immersing the positive electrode material in the lye, the lithium cobaltate does not react with the lye and is decomposed from the metal aluminum The flakes fall off and become black powder, and then rinse to separate the aluminum from the black powder to obtain a black powder with low aluminum content.

[0023] 2) For the above-mentioned black powder, first use dilute sulfuric acid for low-acid dissolution; then use Na 2 SO 5 , or Na 2 SO 3 Or add concentrated sulfuric acid to Fe powder for reduction and dissolution, and the pH value of the solution is controlled at 0.5-2.0; finally, 3-6mol / L sulfuric acid is used for high-acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com