Cathode composite material of lithium ion battery and preparation method thereof

A technology of lithium-ion batteries and composite materials, which is applied in the field of lithium-ion battery negative electrode composite materials and its preparation, can solve the problems of low rate performance, limit the application of lithium-ion batteries, and cannot meet the development needs of power lithium-ion batteries. Simple, conducive to wide application, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention provides a kind of preparation method of negative electrode composite material of lithium ion battery, comprises the following steps:

[0040] Mixing graphene, electrode active material and water to obtain a mixed solution;

[0041] Drying the mixed solution to obtain a lithium-ion battery negative electrode composite material;

[0042] The electrode active material is one or more of mesophase pitch carbon microspheres, silicon, lithium titanate, titanium dioxide, tin dioxide and graphite.

[0043] The invention firstly mixes graphene, electrode active material and water to obtain a mixed solution. In the present invention, before mixing the graphene, the electrode active material and water, the graphene and the electrode active material are preferably ground to obtain the ground graphene and the electrode active material, preferably under ultrasonic conditions, the obtained The ground graphene is mixed with electrode active material and water. ...

Embodiment 1

[0053] The particle size of 0.1g is about 10μm, and the specific surface area is 153m 2 Graphene and 10g mesophase pitch carbon microspheres of / g, electrical conductivity are mixed with 10g mesophase pitch carbon microsphere, after grinding evenly, add 1010mL deionized water wherein, obtain the mixed solution that mixes after ultrasonic dispersion; Described mixed solution is added in In the spray dryer, the flow rate of the mixed solution is controlled to be 3mL / min, the temperature at the inlet is 150°C, and the temperature at the outlet is 50°C, and the lithium-ion battery negative electrode composite material is obtained at the outlet.

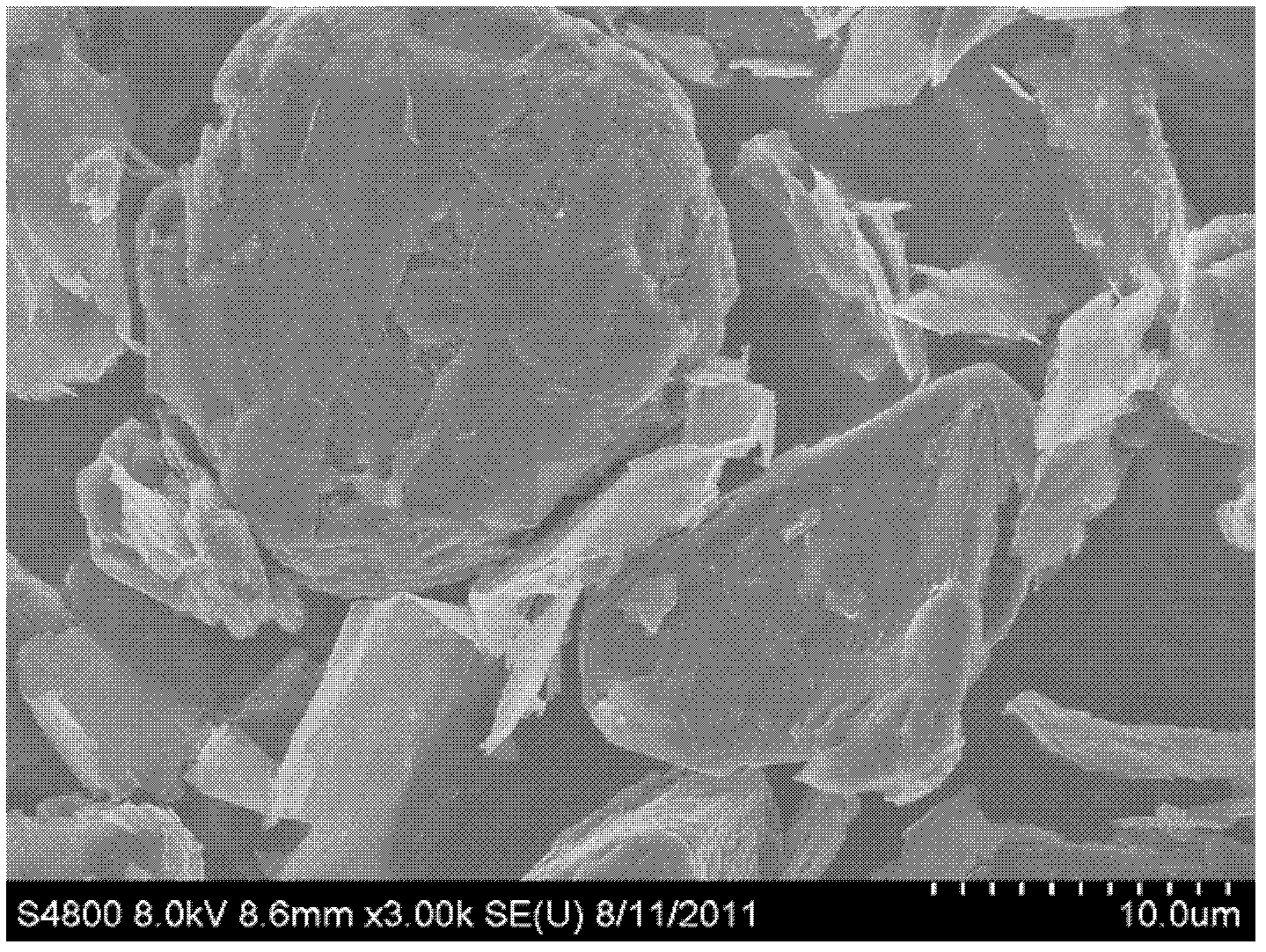

[0054] The present invention carries out scanning electron microscope (SEM) scanning analysis to the negative electrode composite material of lithium ion battery obtained, and the result is as follows: figure 1 as shown, figure 1 The SEM image of the lithium-ion battery negative electrode composite material prepared for Example 1 of the ...

Embodiment 2

[0061] 1g particle size is about 30μm, specific surface area is 150m 2 Graphene and 50g mesophase pitch carbon microspheres mixed with Graphene and 50g mesophase pitch carbon microspheres of / g, electrical conductivity are 715S / cm, after grinding uniformly, add 2550mL deionized water wherein, obtain the mixed solution that mixes after ultrasonic dispersion; Described mixed solution is added in In the spray dryer, the flow rate of the mixed solution is controlled to be 6mL / min, the temperature of the feed port is 200°C, and the temperature of the discharge port is 80°C, and the lithium-ion battery negative electrode composite material is obtained at the discharge port.

[0062] The present invention carries out scanning electron microscope (SEM) scanning analysis to the negative electrode composite material of lithium ion battery obtained, and the result is as follows: Figure 4 as shown, Figure 4 The SEM image of the lithium-ion battery negative electrode composite material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com