Process for preparing one-dimensional nano tin dioxide material

A nano-tin dioxide, raw material technology, applied in tin oxide, nanotechnology, nanotechnology and other directions, can solve problems such as no one-dimensional structure nano SnO2 material research report and other problems, achieve low cost of raw materials and equipment, simple preparation process , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

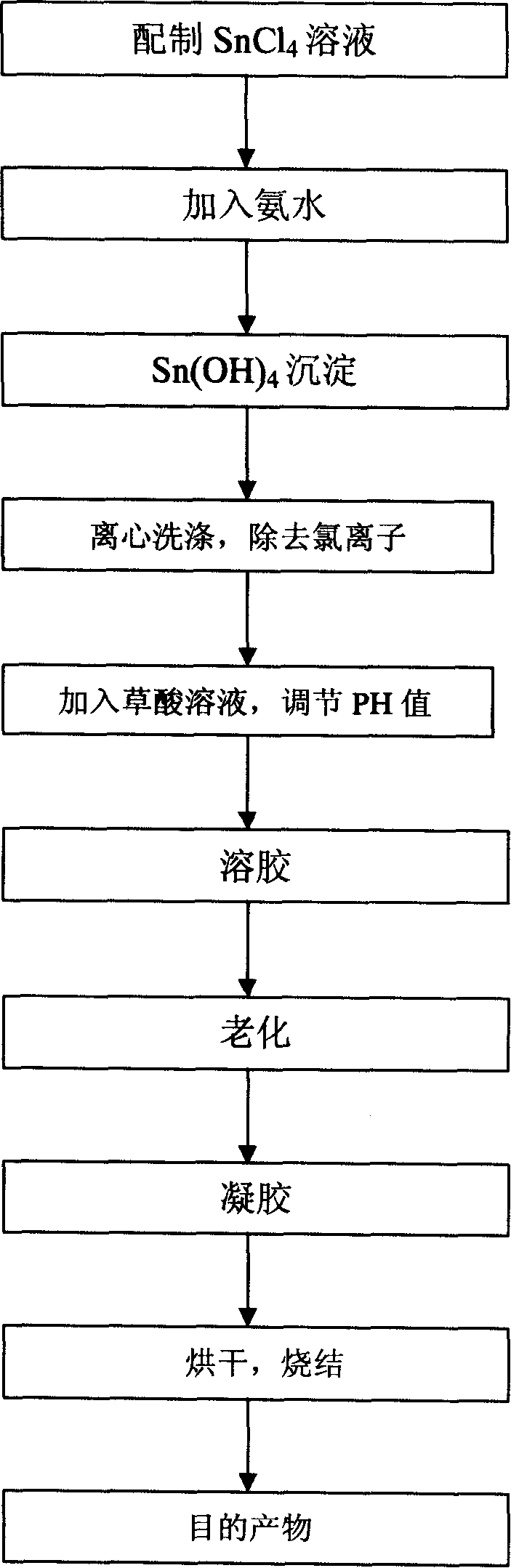

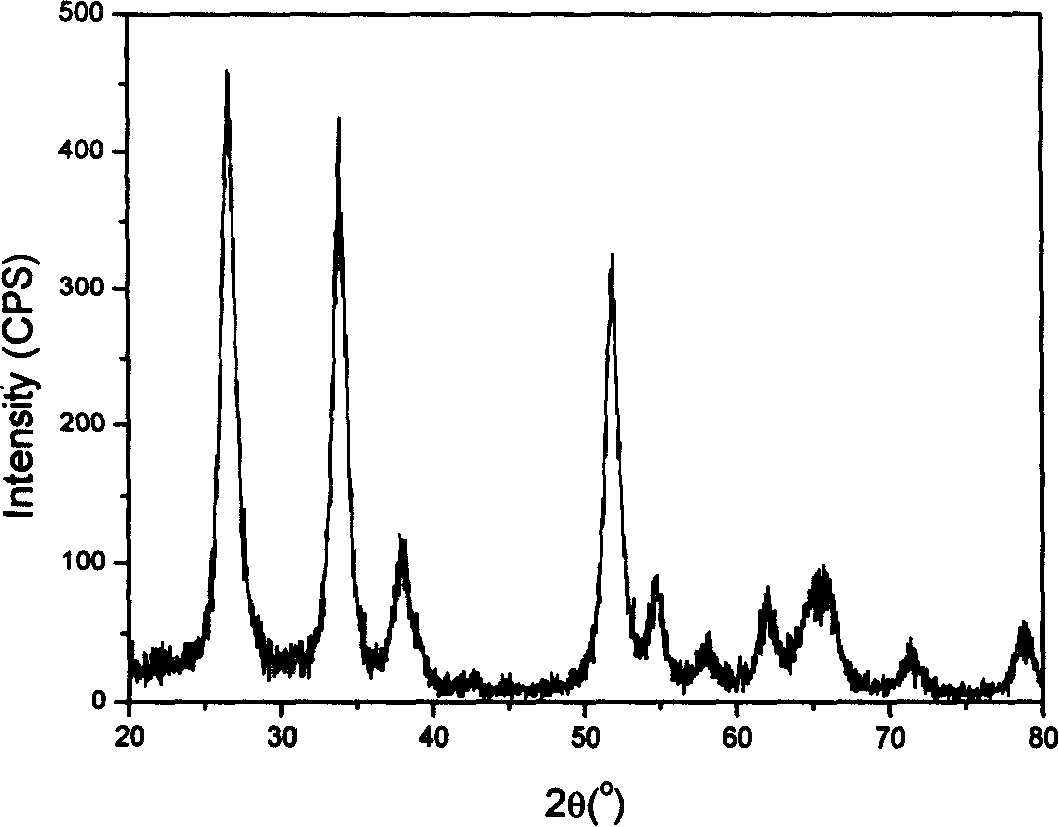

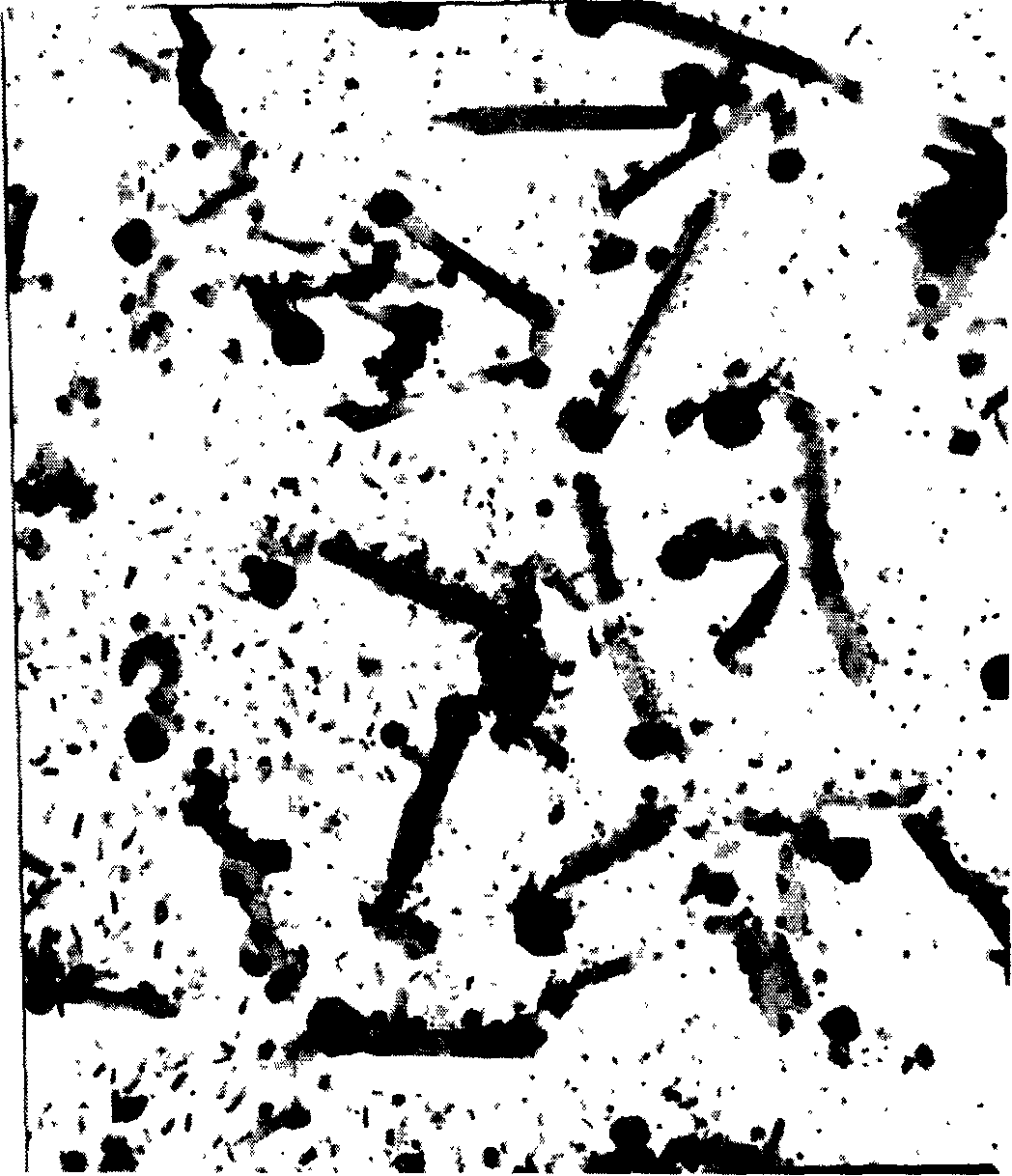

[0029] Analytical grade SnCl 4 ·5H 2 O is dissolved in distilled water (the pH value is adjusted to 1-2 with hydrochloric acid or citric acid to prevent hydrolysis), and a solution with a concentration of 0.5 mol / 1 is prepared. 28% ammonia solution, control the drop rate to be about 1ml / min, until the pH of the solution is about 7-8 to form a precipitate. The precipitate was washed by centrifugation to remove chloride ions (with 0.5mol / 1 AgNO 3 Solution test), add oxalic acid solution to adjust the pH value to 1-2, ultrasonically disperse, heat up to about 50 ℃ under vigorous stirring to form a sol, the sol is aged for 24-48h to form a gel, and the gel is dried at 100 ℃ for 5-8h , 250℃-500℃ resistance furnace sintering for 0.5-1h to obtain the target product. The phase of the sample was analyzed by XRD, the morphology of the sample was analyzed by transmission electron microscope (TEM), the chemical composition of the sample was analyzed by X-ray electron spectroscopy (XPS)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com