Preparation method and application of three-dimensional-structure graphene-base metal oxide composite material

A three-dimensional structure and composite material technology, applied in the fields of materials science and electrochemistry, can solve problems such as poor conductivity, achieve the effects of inhibiting agglomeration, increasing capacity, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The first step is to prepare graphene-based tin dioxide nanosheets:

[0051] (1) Ultrasonic 1 mg / mL graphene oxide in dimethylformamide solution (100 mL) to form a well-mixed dispersion;

[0052] (2) Add 25 mL of water and hydrochloric acid to the above dispersion to adjust the pH of the solution to 3; add tin tetrachloride (SnCl) under vigorous stirring. 4 ·5H 2 O), after adding, keep at 80℃ for 12h, and cool;

[0053] Among them, the added SnCl 4 ·5H 2 The mass dosage ratio of O to graphene oxide is 2.26:1.

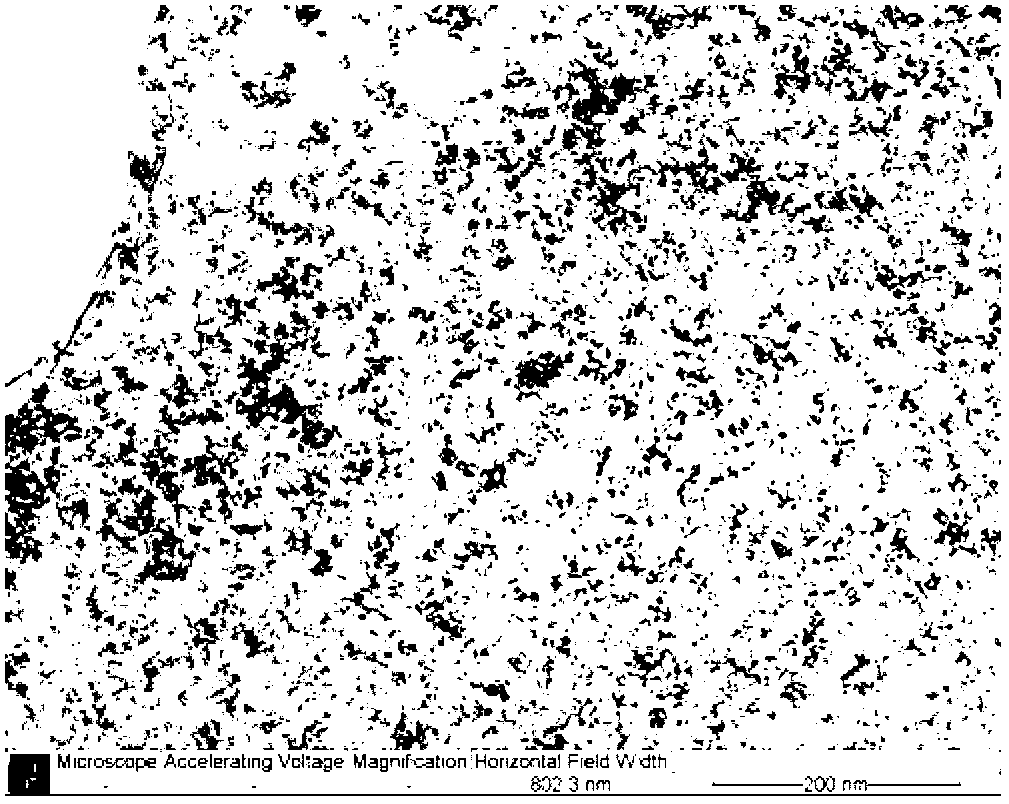

[0054] (3) Centrifuge the above-reacted solution, wash with deionized water, repeat the centrifugation and washing operations three times, and concentrate to a viscous liquid of 5 mg / mL, which is graphene-based tin dioxide nanosheets. TEM images of tin dioxide nanosheets are as follows figure 1 shown.

[0055] The second step is to prepare the graphene-based tin dioxide aerogel with three-dimensional structure:

[0056] (1) Add 1 mL of PVA aqueous solutio...

Embodiment 2

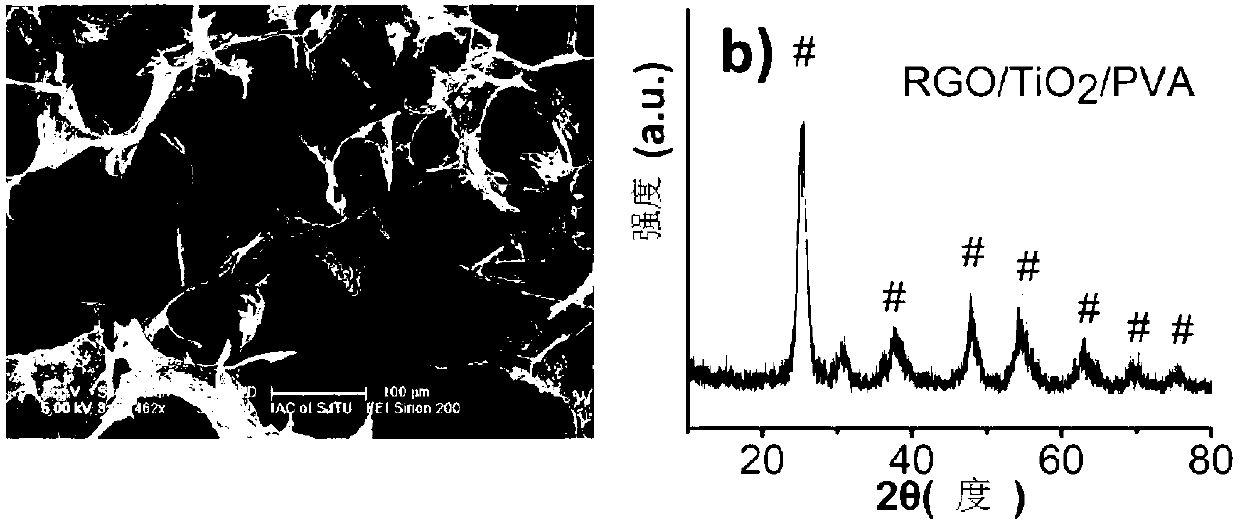

[0062] The first step, preparation of three-dimensional graphene-based titanium dioxide

[0063] (1) Ultrasonic 1 mg / mL graphene oxide in dimethylformamide solution (100 mL) to form a well-mixed dispersion;

[0064] (2) Add 25 mL of water and concentrated sulfuric acid to the above dispersion to adjust the pH of the solution to 1; add tetrabutyl titanate (TBT) in an ice-water bath and under vigorous stirring, keep at 80°C for 12 hours after adding, and cool;

[0065] Wherein, the mass dosage ratio of added TBT to graphene oxide is 1.5:1.

[0066] (3) Centrifuge the above-reacted solution, wash with deionized water, repeat the centrifugation and washing operations three times, and concentrate into a viscous liquid of 5 mg / mL, which is graphene-based titanium dioxide nanosheets.

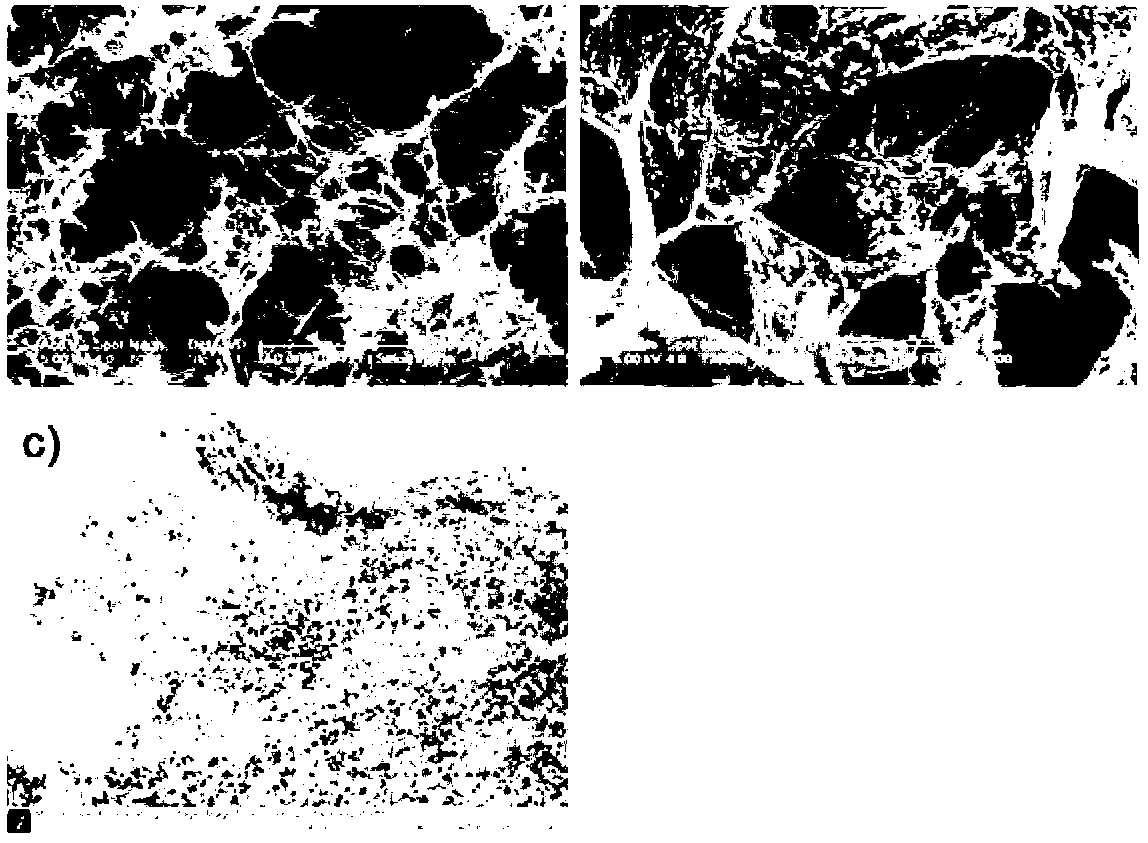

[0067] The second step is to prepare a graphene-based titanium dioxide aerogel with a three-dimensional structure:

[0068] (1) Add 1 mL of PVA aqueous solution to the viscous solution of the above-p...

Embodiment 3

[0073] The first step is to prepare graphene-based tin dioxide nanosheets:

[0074] (1) Ultrasonic 1 mg / mL graphene oxide in dimethylformamide solution (100 mL) to form a well-mixed dispersion;

[0075] (2) Add 25 mL of water and hydrochloric acid to the above dispersion to adjust the pH of the solution to 3; add tin tetrachloride (SnCl) under vigorous stirring. 4 ·5H 2 O), after adding, keep at 80℃ for 12h, and cool;

[0076] Among them, the added SnCl 4 ·5H 2 The mass dosage ratio of O to graphene oxide is 2.26:1.

[0077] (3) Centrifuge the above-reacted solution, wash with deionized water, repeat the centrifugation and washing operations three times, and concentrate into a viscous liquid of 5 mg / mL, which is graphene-based tin dioxide nanosheets.

[0078] The second step is to prepare the graphene-based tin dioxide aerogel with three-dimensional structure:

[0079] (1) Add 1 mL of F127 aqueous solution to the viscous solution of the above-prepared graphene-based tin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com