Preparation method for aluminum-containing continuous silicon nitride fibers

A technology of silicon nitride fibers and polycarbosilane fibers, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of reducing the mechanical strength and quality loss of fibers, and achieve the effects of low cost, simple preparation process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

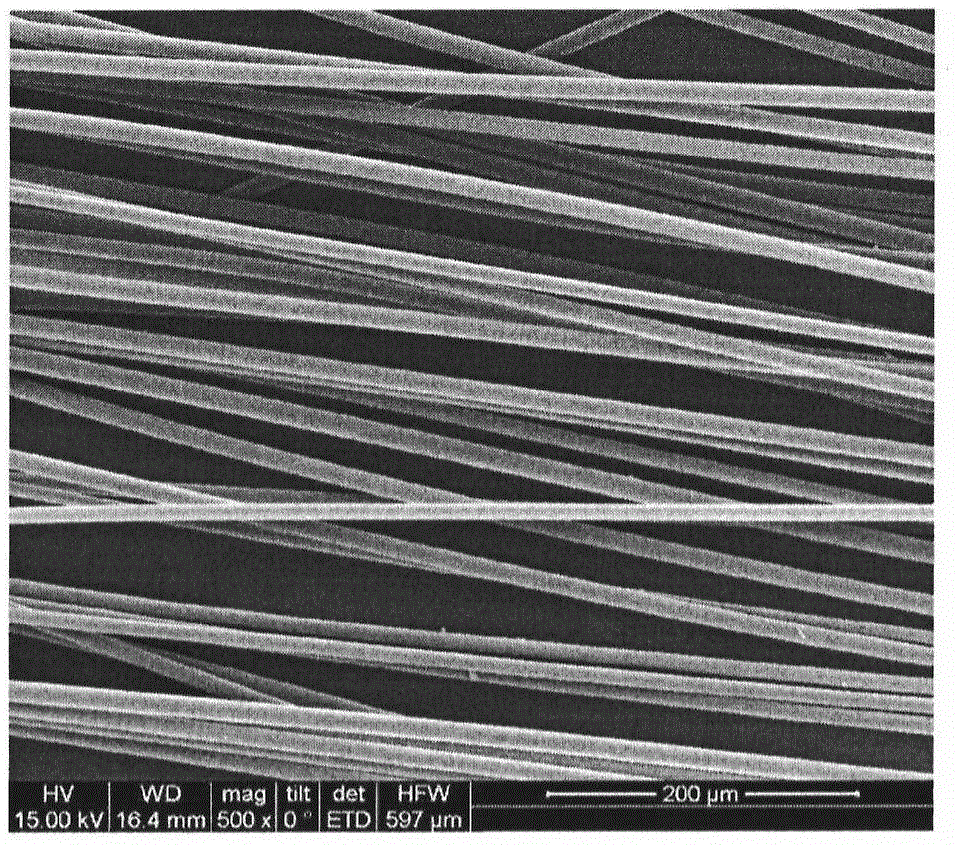

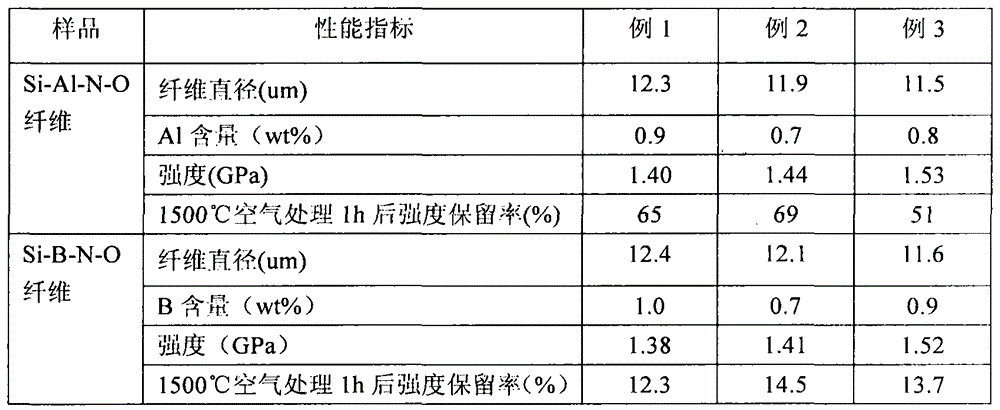

[0019] The polyaluminocarbosilane fiber is treated at 180°C where the air does not melt, and the non-melting aluminum-containing polycarbosilane fiber with a non-melting degree of 65% can be obtained. Place aluminum-containing non-melting polycarbosilane fibers in a high-temperature sintering furnace, feed pure nitrogen, and raise the temperature at a rate of 270°C / h, with a nitrogen flow rate of 10L / min. Start at 200°C, feed ammonia gas, raise the temperature to 800°C at a rate of 120°C / min, keep warm for 1h, and the flow rate of ammonia gas is 5L / min. Then, under the protection of high-purity nitrogen, the temperature continues to rise at a rate of 300°C / min, and the firing is completed at 1500°C under high-temperature conditions, and the flow rate of nitrogen is 15L / min. From figure 1 It can be seen from the figure that the obtained Si-Al-N-O fiber has a diameter of 12.3um, a strength of 1.40GPa, an aluminum content of 0.9%, and a strength retention rate of 65% after being...

Embodiment 2

[0021] The aluminum-containing non-melting polycarbosilane fiber prepared according to the method of Example 1 was placed in a high-temperature sintering furnace, and nitrogen gas was introduced, and the temperature was raised at a rate of 250° C. / h, and the flow rate of nitrogen gas was 10 L / min. Start at 300°C, feed the mixed gas of ammonia and nitrogen, raise the temperature to 800°C at a rate of 150°C / min, keep warm for 2h, the volume concentration of ammonia gas is 50%, and the flow rate is 8L / min. Then under the protection of high-purity nitrogen, continue to heat up at a rate of 300°C / min, and complete the firing under high temperature conditions at 1450°C. The nitrogen flow rate is 20L / min, and the obtained Si-Al-N-O fiber has a diameter of 11.9um and a strength of 1.44GPa, the aluminum content is 0.7%, and the strength retention rate is 69% after being treated in air at 1500°C for 1 hour.

Embodiment 3

[0023] The aluminum-containing non-melting polycarbosilane fiber prepared according to the method of Example 1 was placed in a high-temperature sintering furnace, fed with nitrogen, and the temperature was raised at a rate of 300° C. / h, and the nitrogen flow rate was 10 L / min. Start at 400°C, feed the mixed gas of ammonia and argon, raise the temperature to 800°C at a rate of 100°C / min, keep warm for 1.5h, the volume concentration of ammonia gas is 30%, and the flow rate is 5L / min. Then under the protection of high-purity nitrogen, continue to heat up at a rate of 300°C / min, and complete the firing under high-temperature conditions at 1400°C. The nitrogen flow rate is 15L / min, and the obtained Si-Al-N-O fiber has a diameter of 11.5um and a strength of 1.53GPa, the aluminum content is 0.8%, and the strength retention rate is 51% after being treated in air at 1500°C for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| Strength retention | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com