Dewatering well plugging structure with water and construction method thereof

A construction method and technology for dewatering wells, which are applied in infrastructure engineering, construction, etc., can solve problems such as failure of concrete pouring, influence of bolt reinforcement effect, deformation and damage of flanges, etc., to improve waterproof effect, good practicability, and finished products. Protect the simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

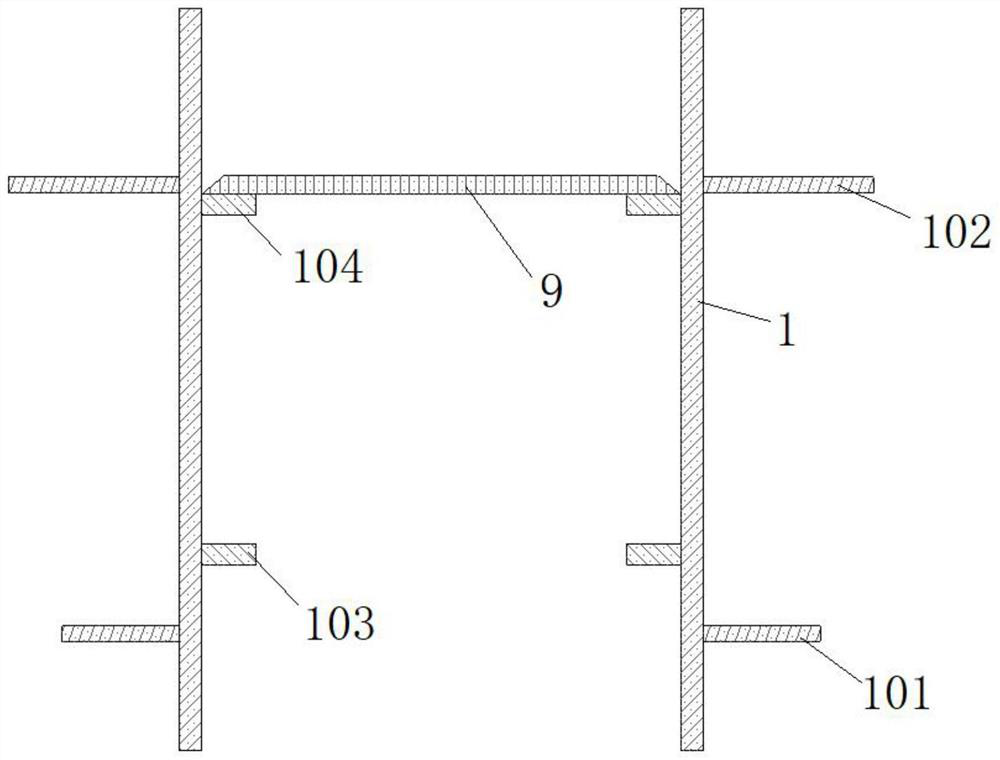

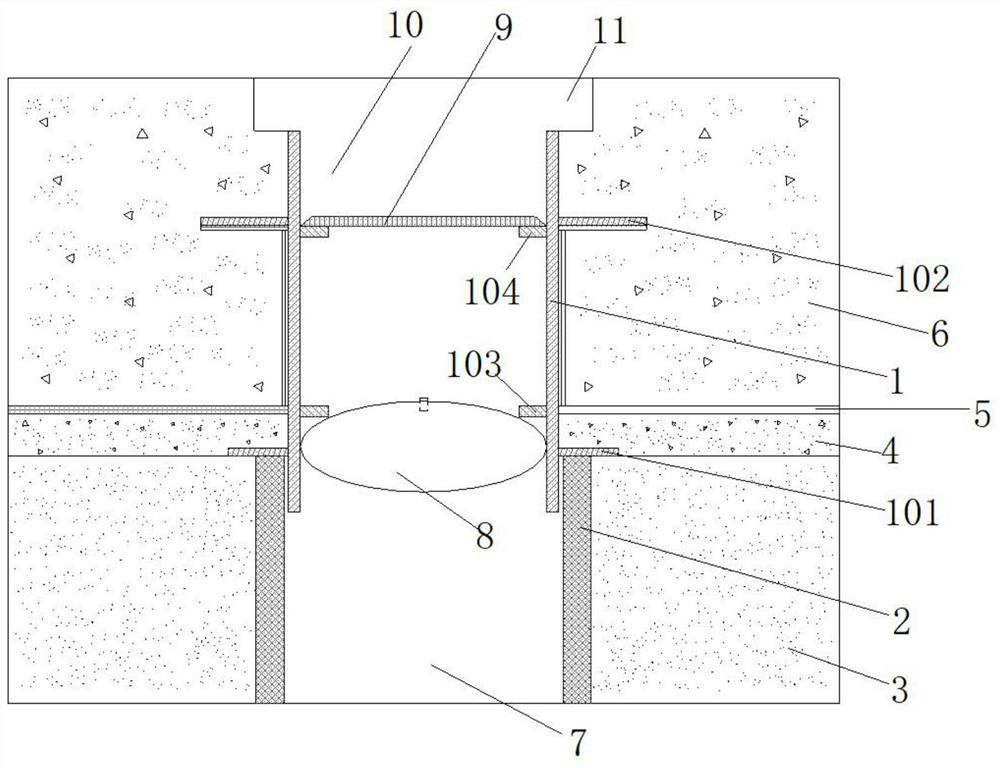

[0027] A water-filled sealing structure for a dewatering well, comprising a longitudinal tubular steel sleeve 1, the lower end of the steel sleeve 1 extends into the upper end of the downcomer 2, and the outer wall of the steel sleeve 1 is sequentially sleeved and connected with Ring plate-shaped lower wing ring plate 101 and upper wing ring plate 102, the lower wing ring plate 101 is placed at the upper end nozzle of the downcomer 2, the downcomer 2 below the lower wing ring plate 101 is arranged in the base layer 3, the lower wing The steel sleeve 1 above the ring plate 101 is filled with concrete cushion 4, waterproof layer 5 and floor concrete 6 from bottom to top, the upper wing ring plate 102 is located in the bottom plate concrete 6; the lower wing ring plate 101 and the upper wing ring plate 102 The inner wall of the steel sleeve 1 at the place is respectively connected with a ring-shaped lower water-stop ring plate 103 and an upper water-stop ring plate 104, the downco...

Embodiment 2

[0042] A water-carrying plugging structure for a dewatering well is similar to Embodiment 1, except that the inflatable bag 8 is a rubber air bag.

[0043] It is also possible that the longitudinal centerlines of the steel sleeve 1 , the downcomer 2 , the lower wing ring plate 101 and the upper wing ring plate 102 , the lower water stop ring plate 103 and the upper water stop ring plate 104 are all coincident.

[0044] The water-carrying plugging structure of the dewatering well of the present invention and its construction method are convenient and reliable through the use of rubber inflatable bags 8 and concrete layered pouring, and the construction materials are economical and environmentally friendly, and water-proof operations are realized. In specific waterproof construction , the waterproof material is on the water-facing surface, and its waterproof effect is better than that of the back-water surface, so that it can be blocked when there is water. Generally, the inflati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com