Manganese oxide electrode material with metal cation intercalation structure and preparation method and application thereof

A technology of metal cations and manganese oxides, applied in battery electrodes, structural parts, hybrid capacitor electrodes, etc., can solve the problems of non-rational preparation methods of binary or multi-element metal oxides, high crystallinity of materials, and unfriendly environment. Achieve the effect of controllable metal ion content, simple and controllable process, and low requirements for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

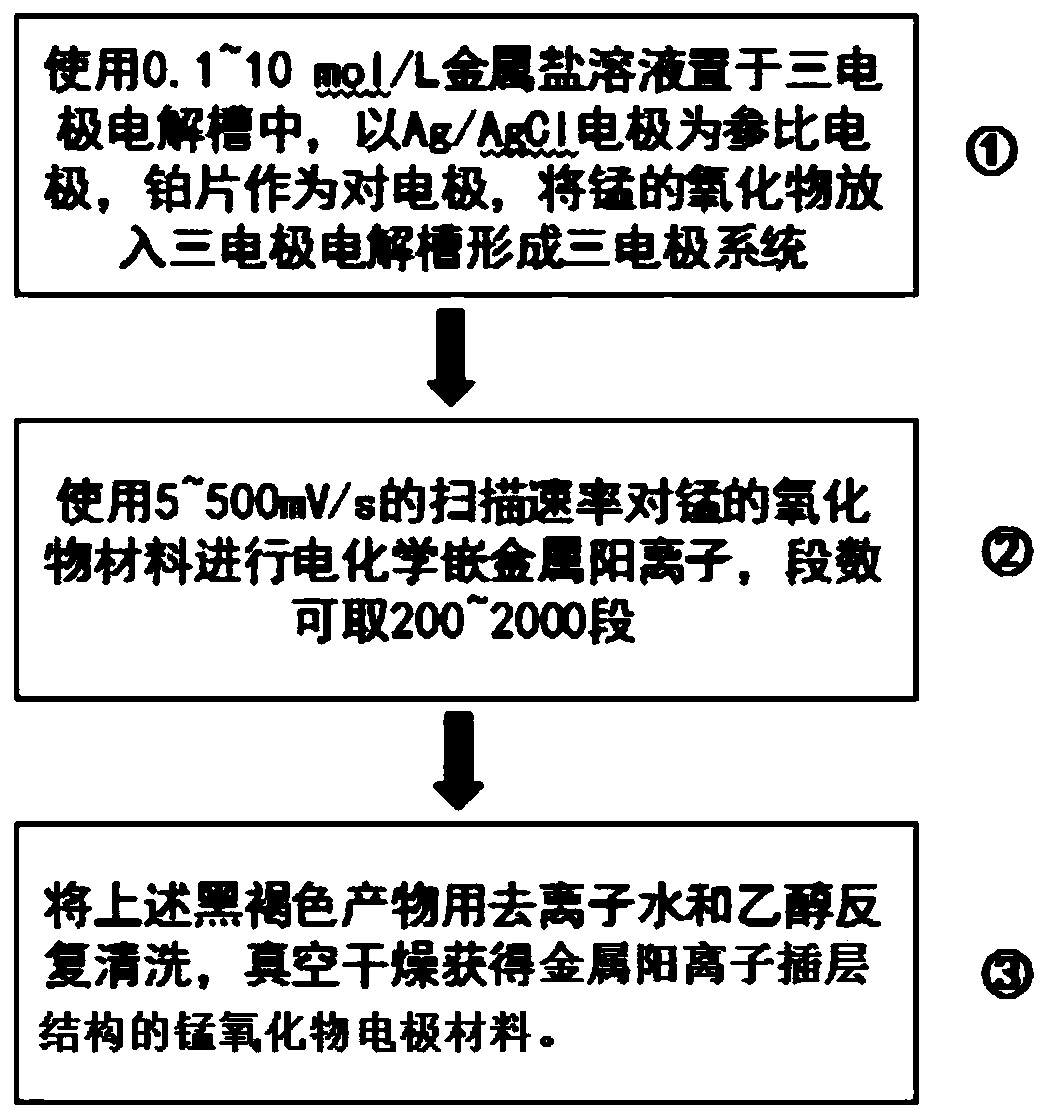

[0041] A kind of lithium intercalation Mn of the present embodiment 3 o 4 The preparation method of Li-Mn-O material, described method specifically comprises the steps:

[0042] (1) Mix 150mL of 1mol / L well-stirred CH 3 The COOLi solution was placed in a three-electrode electrolytic cell, with an Ag / AgCl electrode as a reference electrode, 1 cm 2 The Pt sheet is used as the counter electrode, and the Mn deposited on the carbon cloth is placed in advance. 3 o 4 The array of nanosheets forms a three-electrode electrolytic cell system.

[0043] (2) Using electrochemical cyclic voltammetry in Mn 3 o 4 Lithium is intercalated on the surface of the nanosheet array. The specific process parameters of the cyclic voltammetry are as follows: the initial potential is set to 0V, the end potential is set to 1.3V, the scan rate is 5mV / s, and the number of scan segments is 1000.

[0044] (3) After the electrochemical reaction, the obtained dark brown product was repeatedly washed with...

Embodiment 2

[0048] A kind of cesium intercalation MnO of the present embodiment 2 The preparation method of the Cs-Mn-O material, described method specifically comprises the following steps:

[0049] (1) Mix 150mL 2mol / L CsNO 3 The solution is placed in a three-electrode electrolytic cell, with an Ag / AgCl electrode as a reference electrode, 1cm 2 The Pt sheet is used as the counter electrode, and the MnO deposited on the nickel foam is placed in advance. 2 Nanorod arrays form a three-electrode electrolytic cell system.

[0050] (2) Using electrochemical cyclic voltammetry in MnO 2 Cesium is embedded on the surface of the nanorod array. The specific process parameters of the cyclic voltammetry are as follows: the initial potential is set to 0V, the end potential is set to 1.3V, the scan rate is 50mV / s, and the number of scan segments is 500.

[0051] (3) After the electrochemical reaction is over, the obtained dark brown product is repeatedly washed with deionized water and ethanol, an...

Embodiment 3

[0054] A kind of preparation method of the Co-Mn-O material of cobalt intercalation MnO of the present embodiment, described method specifically comprises the following steps:

[0055] (1) Mix 150mL 5mol / L CoSO 4 The solution is placed in a three-electrode electrolytic cell, the Ag / AgCl electrode is used as a reference electrode, 1cm 2 The Pt sheet is used as the counter electrode, and the MnO nanoparticles deposited on the carbon nanotubes are placed in advance to form a three-electrode electrolytic cell system.

[0056] (2) Cobalt embedding on the surface of MnO nanoparticles by electrochemical cyclic voltammetry, the specific process parameters of the cyclic voltammetry are as follows: the initial potential is set to 0V, the termination potential is 1.3V, and the scan rate is 100mV / s, The number of scanning segments is 2000 segments.

[0057] (3) After the electrochemical reaction, the obtained dark brown product was repeatedly washed with deionized water and ethanol, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com