Manufacturing method of all-solid-state sodium ion battery and all-solid-state sodium ion battery

A sodium-ion battery, all-solid-state technology, applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of poor ion transmission channels, poor ion conductivity of solid electrolytes, etc., to avoid serious gas production , Improve the rate performance, improve the effect of ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

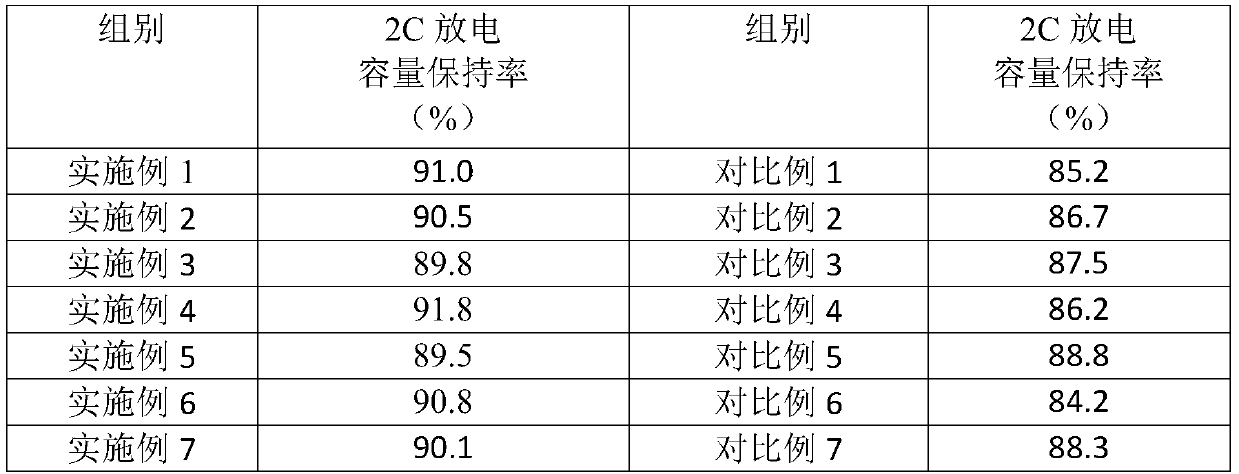

Examples

Embodiment 1

[0028] 1. Preparation of liquid mixture:

[0029] In a nitrogen-filled glove box (O 2 2(0<3ppm), ethylene carbonate, propylene carbonate, ethyl methyl carbonate and diethyl carbonate are mixed uniformly according to the mass ratio 2:1:4:3 to obtain an organic solvent; then take the total mass of the liquid mixed solution 85% organic solvent, to which 1% polyethylene glycol diacrylamide, 1.5% polyethylene glycol diacrylate, 0.5% methyl methacrylate and 0.3% ethylene are added based on the total mass of the liquid mixture base vinyl sulfite additive, and azobisisobutyronitrile initiator with a total mass of 0.2% of the liquid mixture; then slowly add a mixture of sodium hexafluorophosphate and sodium bisfluorosulfonimide to prepare a 1mol / L sodium salt The solution, wherein sodium hexafluorophosphate accounts for 11.0% of the total mass of the liquid mixture, is mixed uniformly to make the liquid mixture.

[0030] 2. Preparation of positive pole piece:

[0031] The positive e...

Embodiment 2

[0037] 1. Preparation of liquid mixture:

[0038] In a nitrogen-filled glove box (O 2 2 (0<3ppm), mix ethylene carbonate, propylene carbonate, methyl trifluoroethyl carbonate, propyl propionate and diethylene glycol dimethyl ether in a mass ratio of 2:1:2:3:2 Uniformly, make organic solvent; Then get the organic solvent that accounts for 87% of liquid mixed liquid gross mass, add wherein based on liquid mixed liquid gross mass 1% polyethylene glycol diacrylamide, 1% pentaerythritol triacrylate, 0.4 % vinyl acetate and 0.3% vinyl sulfite additives, and 0.3% azobisisoheptanonitrile initiator of the total mass of the liquid mixture; then slowly add sodium hexafluorophosphate, sodium perchlorate and tetrafluoro The mixture of sodium borate is prepared into a 1mol / L sodium salt solution, in which sodium hexafluorophosphate accounts for 9.0% of the total mass of the liquid mixture, and the liquid mixture is made after uniform mixing.

[0039] 2. Preparation of positive pole piece:...

Embodiment 3

[0046] 1. Preparation of liquid mixture:

[0047] In a nitrogen-filled glove box (O 2 2 (0<3ppm), ethylene carbonate, propylene carbonate, fluoroethylene carbonate, tetraethylene glycol dimethyl ether and triethylene glycol dimethyl ether according to the mass ratio of 2:1:2:2:3 Mix evenly to obtain an organic solvent; then take the organic solvent accounting for 82% of the total mass of the liquid mixed liquid, and add 1% polyethylene glycol diacrylamide, 1% polyethylene glycol diacrylamide based on the total liquid mixed liquid Acrylates, 0.5% methyl methacrylate and 0.2% ethoxylated trimethylolpropane triacrylate additives, and 0.3% dimethyl azobisisobutyrate and peroxide Dibenzoyl initiator; slowly add sodium hexafluorophosphate, sodium hexafluoroarsenate and sodium bistrifluoromethanesulfonylimide mixture to prepare a 1.2mol / L sodium salt solution, wherein sodium hexafluorophosphate accounts for 12.0% of the total mass of the liquid mixed liquid, which can be made into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com