Manufacturing method for super-hydrophobic metal surface

A metal surface, super-hydrophobic technology, applied in the field of preparation of super-hydrophobic metal surface, can solve the problems of difficult industrialization, expensive operation of equipment, difficult scale application, etc., and achieve the effects of low cost, broad application prospect and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

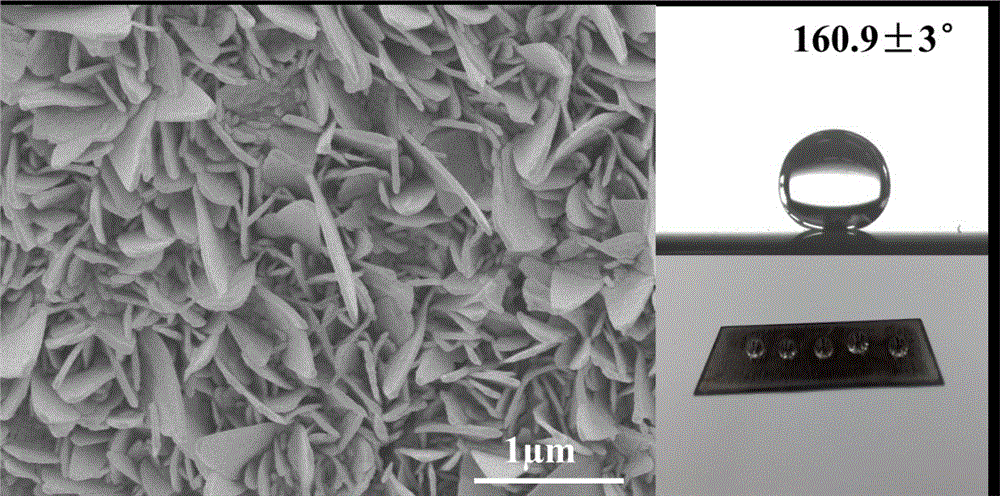

[0022] Embodiment 1: the preparation of superhydrophobic iron sheet

[0023] 1. Cut the iron sheet with a thickness of 0.3mm into 40mm×80mm, and polish it with 400-grit sandpaper. The grinding method is as follows figure 1 As shown, the polished iron piece was then ultrasonicated in acetone and absolute ethanol for 10 minutes.

[0024] 2. Heat the pretreated iron sheet to 500°C at a heating rate of 10°C / min in a muffle furnace, keep the temperature constant for 4 hours, and then cool naturally.

[0025] 3. Put the heat-treated iron sheet into the pre-prepared 1wt.% fluorosilane ethanol solution for modification for 12 hours, the stirring speed is 160 rpm, then take it out, wash it with absolute ethanol, and cure it at 100°C for 2 hours Iron flakes with superhydrophobic surfaces can be obtained in hours. The superhydrophobic properties of the resulting product are as follows: figure 2 shown.

Embodiment 2

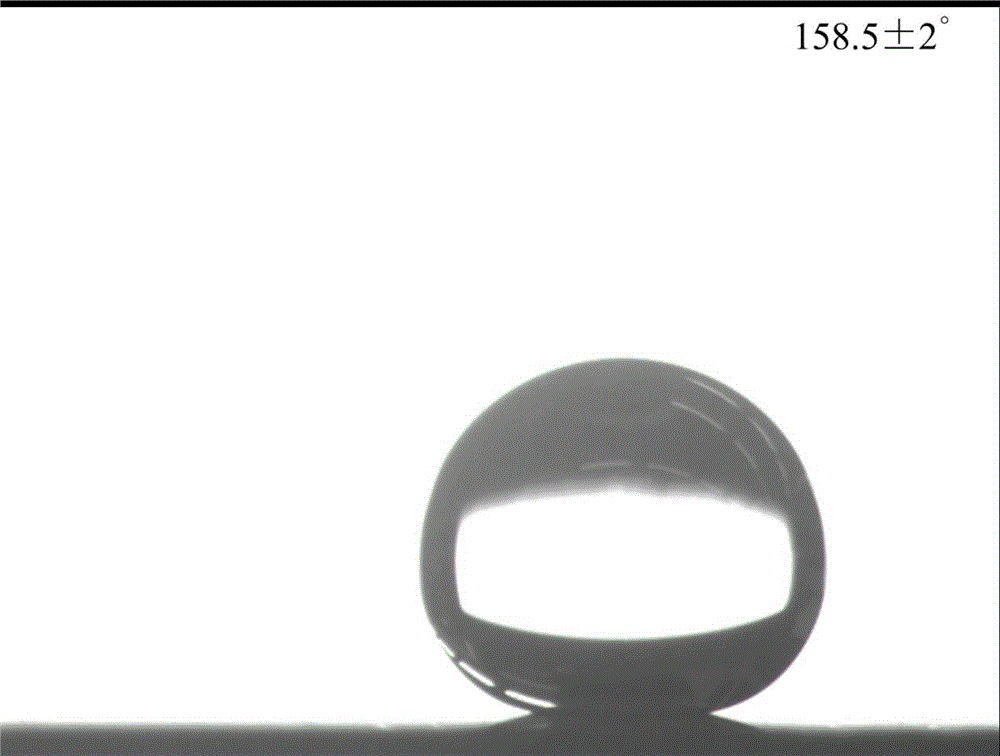

[0026] Embodiment 2: the preparation of superhydrophobic aluminum sheet

[0027] 1. Cut an aluminum sheet with a thickness of 0.1mm into 100mm×100mm, and use an 80# grinding wheel to evenly polish the surface of the aluminum sheet. After polishing, the aluminum sheet is ultrasonicated in acetone and absolute ethanol for 15 minutes.

[0028] 2. Heat the pretreated aluminum sheet to 160°C in an oven at a heating rate of 15°C / min, keep the temperature constant for 2 hours, and then cool naturally.

[0029] 3. Put the heat-treated aluminum sheet into the pre-prepared 50wt% oleic acid anhydrous ethanol solution for modification for 6 hours, the stirring speed is 180 rpm, then take it out, and cure it at 80°C for 2 hours to obtain Aluminum sheet with superhydrophobic surface. The superhydrophobic properties of the resulting product are as follows: image 3 shown.

Embodiment 3

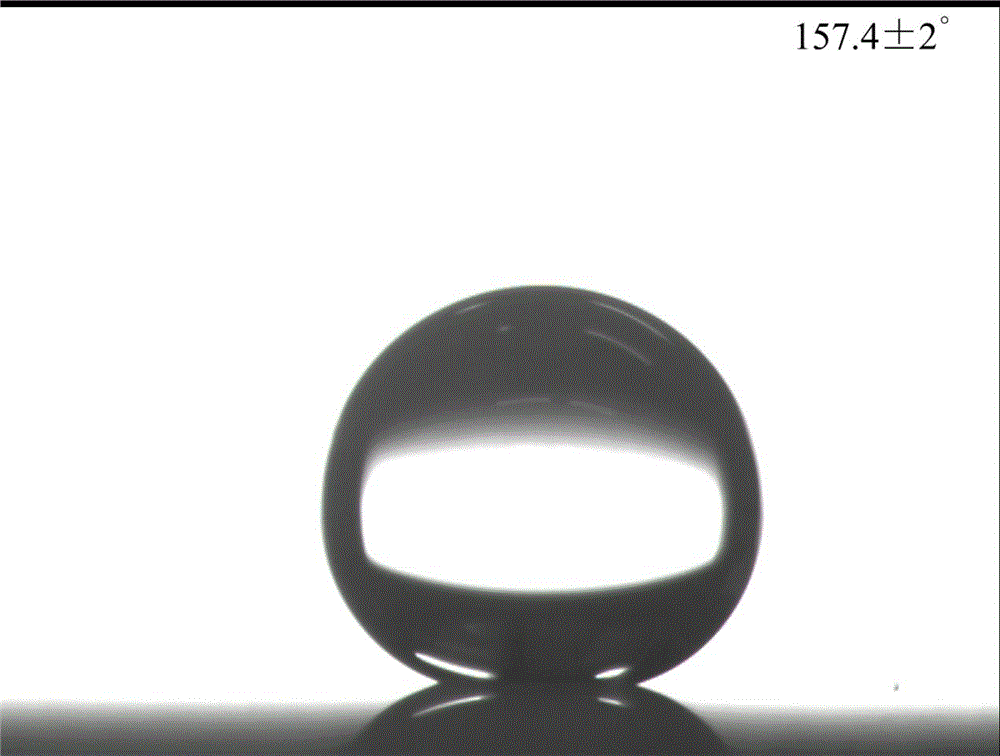

[0030] Embodiment 3: the preparation of superhydrophobic copper sheet

[0031] 1. Cut a copper sheet with a thickness of 0.15mm into 40mm×60mm, polish it with 240-grit sandpaper, and then ultrasonicate it in acetone and absolute ethanol for 10 minutes.

[0032] 2. Heat the pretreated copper sheet to 300°C at a heating rate of 3°C / min, keep the temperature constant for 4 hours, and then cool naturally.

[0033] 3. Put the heat-treated copper sheet into the pre-prepared 0.05mol / L n-dodecylmercaptan ethanol solution for modification for 80 minutes, the stirring speed is 180 rpm, then take it out, and heat it at 60°C After curing for 50 minutes, a copper sheet with a superhydrophobic surface can be obtained. The superhydrophobic properties of the resulting product are as follows: Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com