Preparation and application of boat-fruited sterculia seed residue based sulfur-doped porous carbon

A sulfur-doped, porous carbon technology, applied in the preparation/purification of carbon, nanotechnology for materials and surface science, carbon compounds, etc., can solve problems such as strong corrosion performance, complex operation of template method, and difficult control. Achieve the effect of adjustable sulfur content, controllable pore size distribution and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

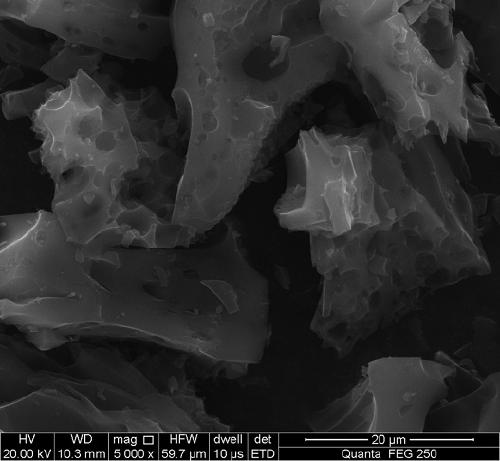

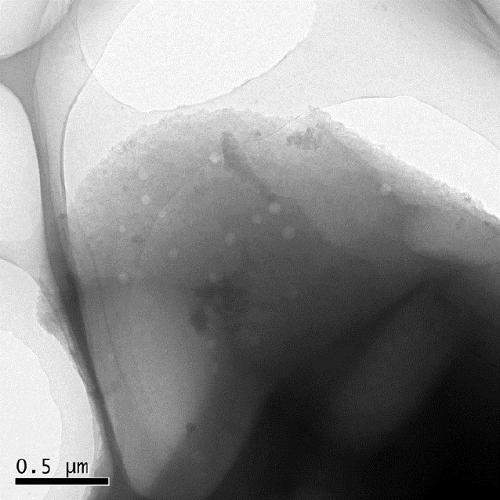

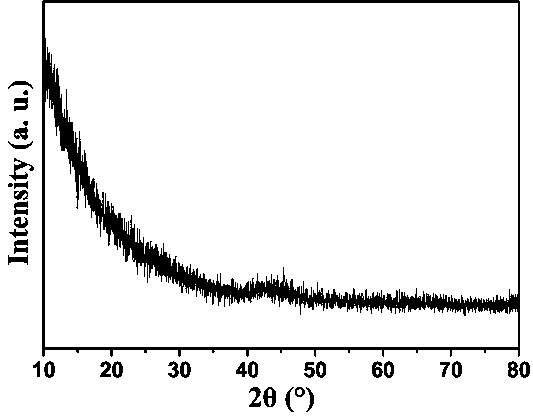

[0027] A preparation of sulfur-doped porous carbon based on fat sea slag, the steps are as follows:

[0028] (1) Peel and remove the seeds from the Panda Sea after making tea, put it into a freeze dryer for freeze-drying, the temperature of freeze-drying is -60°C, the vacuum degree is less than 20pa, and the time is 21h, and then it is crushed with an FZ102 plant grinder , the rotating speed is 1400r / min, through a 100-mesh sieve, to obtain fat sea slag powder;

[0029] (2) Put the fat sea slag powder and cysteine with a mass ratio of 20:2 into a nickel crucible, add an equal volume of alcohol and water, mix well and let it stand for 24 hours, and then put it in a vacuum drying oven at 105°C Internal drying for 11 hours, and then the dried product was subjected to high-temperature carbonization in an argon atmosphere with a mass fraction of 99.99%, the gas flow rate was 150 sccm; the high-temperature carbonization temperature was 800°C, the heating rate was 6°C / min, and the ...

Embodiment 2

[0035] A preparation of sulfur-doped porous carbon based on fat sea slag, the steps are as follows:

[0036] (1) Take the fat sea after making tea, peel and remove the seeds, put it into a freeze dryer for freeze drying, the freeze drying temperature is -70°C, the vacuum degree is less than 20pa, and the time is 20h, and then crush it with an FZ102 plant grinder , the rotating speed is 1400r / min, through a 100-mesh sieve, to obtain fat sea slag powder;

[0037] (2) Put fat sea slag powder and sulfur with a mass ratio of 20:1 into a nickel crucible, add an equal volume of alcohol and water, mix well and let it stand for 24 hours, then put it in a vacuum oven at 100°C for drying 10h, and then the dried product was subjected to high-temperature carbonization in a nitrogen atmosphere with a mass fraction of 99.99%, the gas flow rate was 100sccm; the high-temperature carbonization temperature was 700°C, the heating rate was 3°C / min, and the treatment time was 1h, and the carbonized...

Embodiment 3

[0040] A preparation of sulfur-doped porous carbon based on fat sea slag, the steps are as follows:

[0041] (1) Take the fat sea after making tea, peel and remove the seeds, put it into a freeze dryer for freeze drying, the freeze drying temperature is -50°C, the vacuum degree is less than 20pa, and the time is 24h, and then crush it with an FZ102 plant grinder , the rotating speed is 1400r / min, through a 100-mesh sieve, to obtain fat sea slag powder;

[0042] (2) Put the fat sea slag powder and cystine with a mass ratio of 20:3 into a nickel crucible, add an equal volume of alcohol and water, mix well and let it stand for 24 hours, then put it in a vacuum drying oven at 110°C After drying for 12 hours, the dried product was subjected to high-temperature carbonization in a helium atmosphere with a mass fraction of 99.99%, the gas flow rate was 300 sccm; the high-temperature carbonization temperature was 900°C, the heating rate was 7°C / min, and the treatment time was 4h. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com