Superhydrophobic modified electrostatically-spun membrane and preparation method and application thereof

A superhydrophobic modification and electrospinning technology, which is applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems affecting the porosity of the membrane, improve the membrane flux, prevent membrane wetting, and the preparation process is simple and easy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

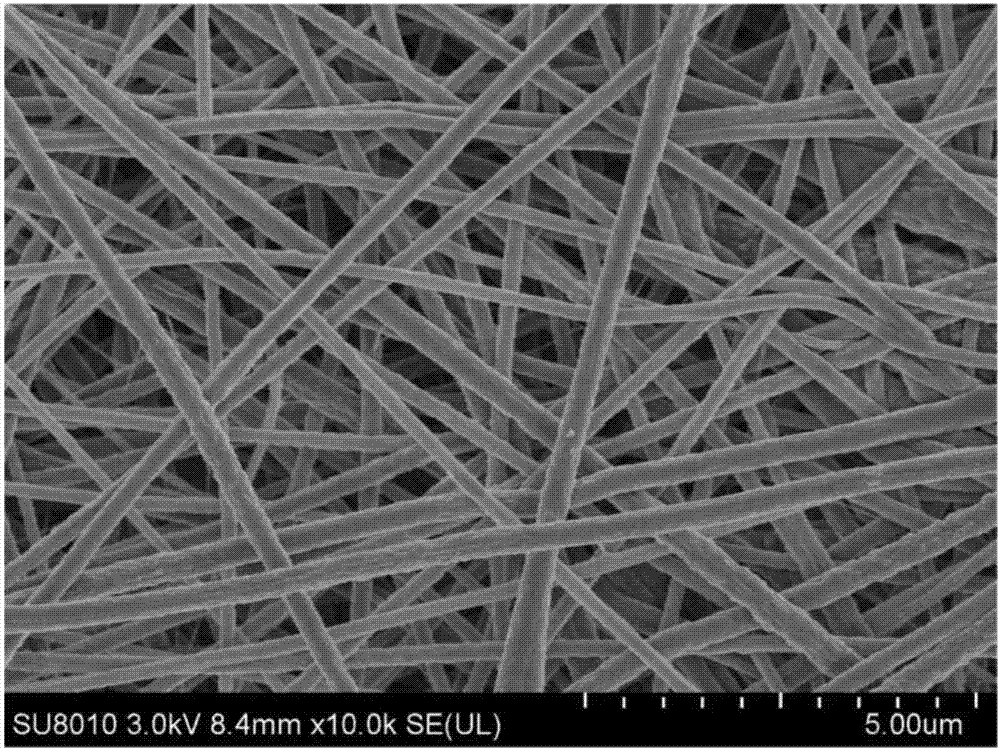

[0039] In this example, a polyvinylidene fluoride electrospun membrane covered with a carbon nanotube network for membrane distillation with a pore size of 0.20 μm was prepared. The specific preparation method includes the following steps:

[0040] (1) Dissolve 5 parts of polyvinylidene fluoride (molecular weight 1.10 to 1.2 million) and 0.004 part of lithium chloride in 76 parts of N,N-dimethylformamide and 19 parts of acetone mixed solvent, and keep the temperature in a water bath at 50°C Stirring and reflux for 4 hours to obtain a uniform and stable polyvinylidene fluoride polymer spinning solution, which was allowed to stand overnight to remove air bubbles;

[0041] (2) Electrospinning the polyvinylidene fluoride polymer spinning solution for 16 hours to prepare a polyvinylidene fluoride electrospinning membrane. In the electrospinning process, the needle of the syringe is a flat needle, and the needle is connected to the positive electrode of the high-voltage power supply...

Embodiment 2

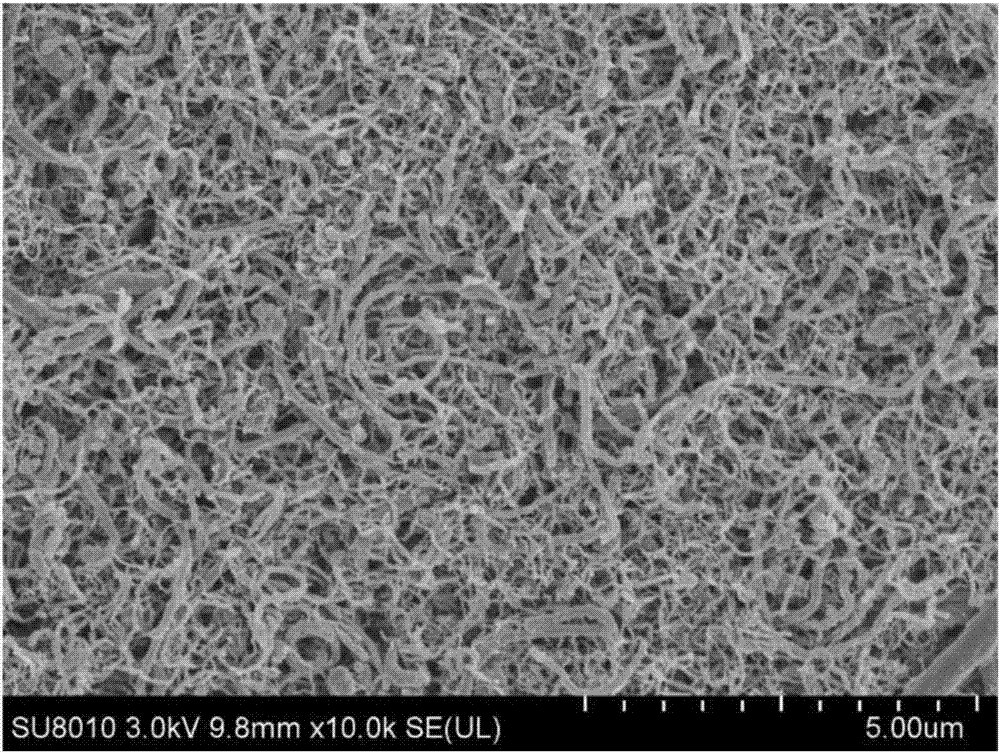

[0048] In this example, a vinylidene fluoride hexafluoropropylene copolymer electrospun membrane covered with a carbon nanotube network with a pore size of 0.29 μm was prepared. The specific preparation method includes the following steps:

[0049] (1) Dissolve 13 parts of vinylidene fluoride hexafluoropropylene copolymer (molecular weight: 455,000) and 0.004 part of sodium chloride in 85 parts of dimethylacetamide solvent, and stir at a constant temperature in a water bath at 55°C for 4 hours to obtain a uniform Stable vinylidene fluoride hexafluoropropylene copolymer spinning solution, the solution was allowed to stand overnight to remove air bubbles;

[0050] (2) Electrospinning the vinylidene fluoride hexafluoropropylene copolymer spinning solution for 13 hours to prepare a vinylidene fluoride hexafluoropropylene copolymer electrospinning membrane. Wherein the needle of the syringe is a flat needle, the needle is connected to the positive pole of the high-voltage power sup...

Embodiment 2

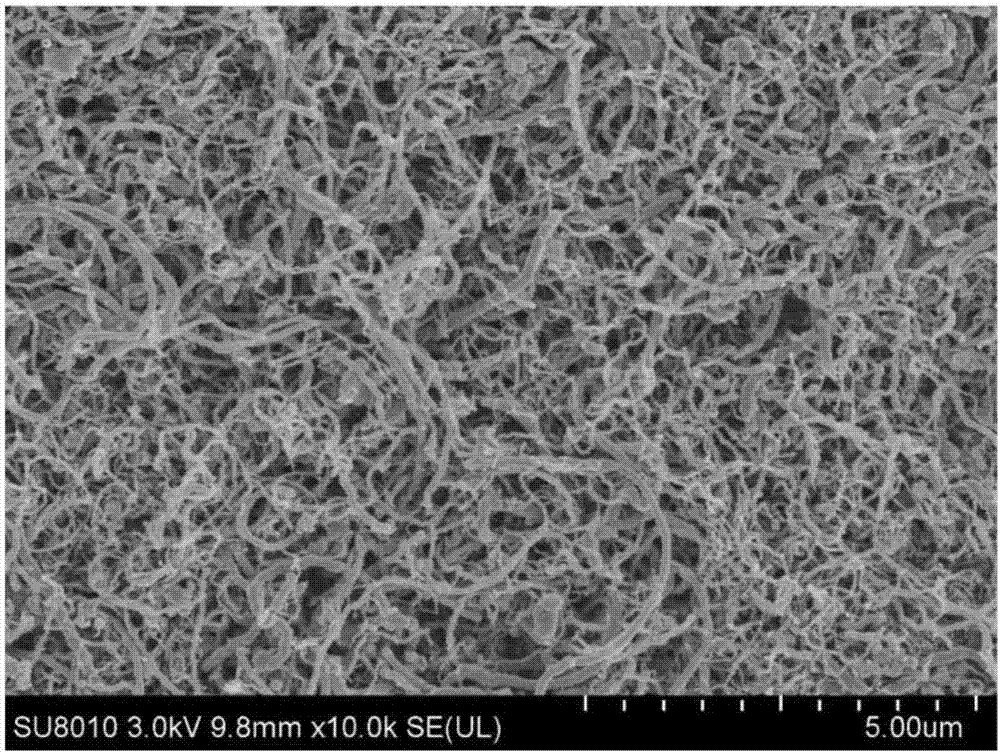

[0054] The electrospun membrane covered with carbon nanotube network for membrane distillation prepared in Example 2 is tested for water contact angle, and its water contact angle is 161.0°, and its minimum osmotic pressure test is 178kPa;

[0055] The surface structure of the electrospun membrane covered with a carbon nanotube network for membrane distillation prepared in Example 2 was observed, and the carbon nanotubes on the surface of the electrospun membrane covered with a carbon nanotube network for membrane distillation were found to be uniform under a scanning electron microscope. The surface morphology of the membrane after the membrane distillation test was analyzed, and it was found that the morphology of the carbon nanotubes on the surface did not change, indicating that the carbon nanotubes were firmly combined with the polyvinylidene fluoride electrospun membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com