Comprehensive recovery method for ferro-sulphur ore containing copper, zinc and iron multi-metal

A recycling method, pyrite technology, applied in the field of metallurgy, can solve problems such as environmental pollution, impact on economic benefits, metal loss, etc., to achieve the effect of improving the surrounding environment, expanding the scope of application, and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

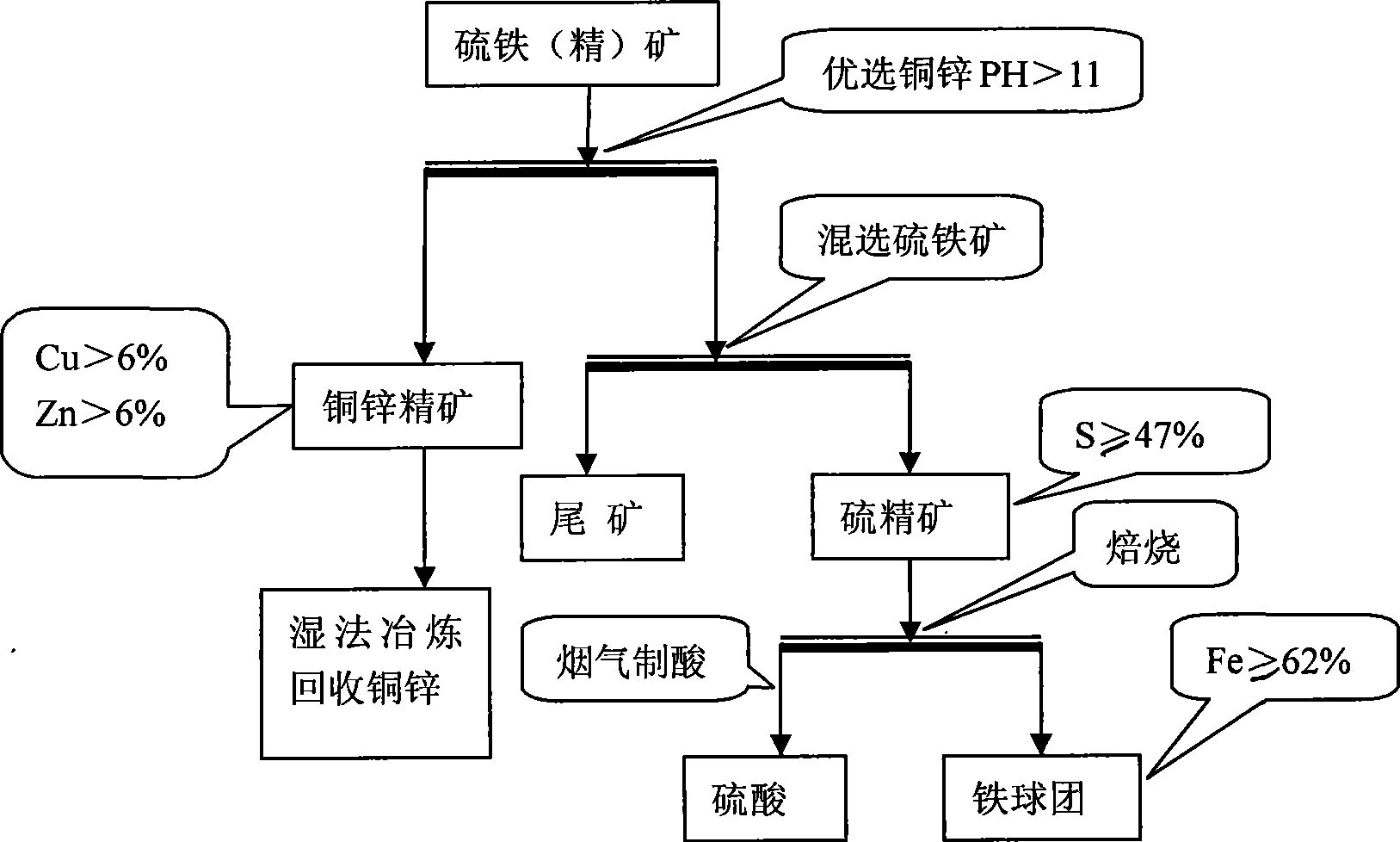

[0014] Such as figure 1 Shown, the comprehensive recovery method of the copper-zinc-iron polymetallic in pyrite ore of the present invention comprises the following steps: in pyrite (concentrate) ore, add strong inhibitor lime earlier, to control pH ≥ 11, then add ethyl sulfide Urethane (Z-200) is used as a collector, and the amount of collector added is 150g / t. No. 2 oil is added as a foaming agent, wherein the amount of No. 2 oil added is 50g / t, and copper and zinc are preferentially flotation, Cu ≥ 6% and Zn ≥ 6% in the flotation copper-zinc concentrate, adopt hydrometallurgy process to recover copper and zinc, specifically: the copper-zinc concentrate obtained by flotation is subjected to sulfuration roasting at 1000°C , the flue gas is recycled for the production of sulfuric acid, and the roasted slag contains H 2 SO 4 Leach in an acid leaching tank with a concentration of 1M. The leached ore pulp is thickened and washed by a thickener, and the liquid flow from the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com