Modified alkyl glycoside high-temperature-resistant inhibitor as well as preparation method and application thereof

An alkyl glycoside and high temperature resistance technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that the inhibition performance and temperature resistance performance need to be improved, cannot meet the high temperature formation suppression and anti-slump, and high cost, and achieve High inhibition and anti-slump performance, favorable on-site application, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

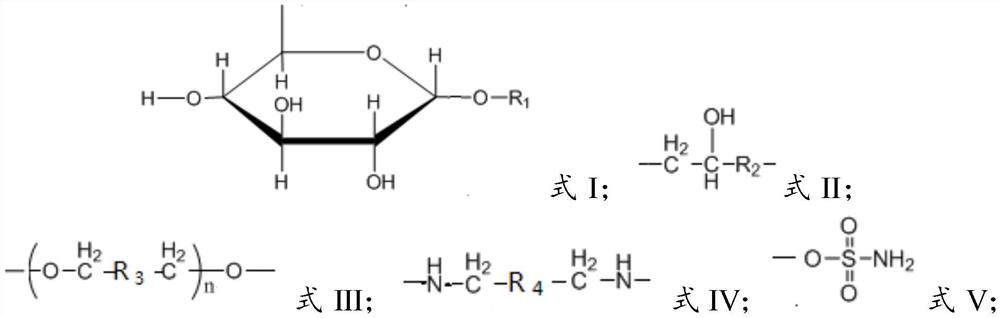

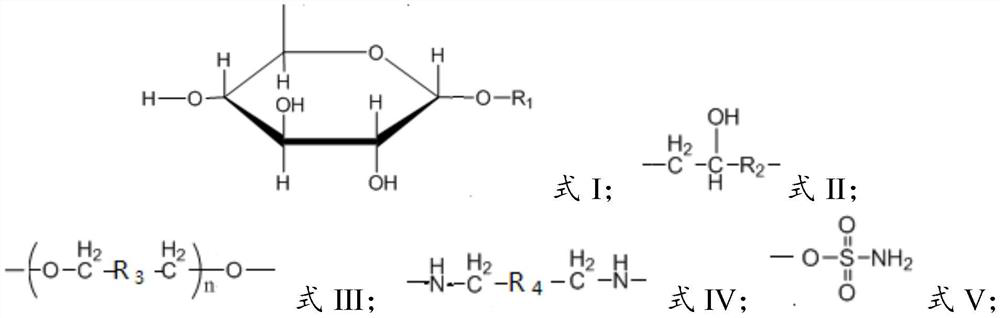

[0043] In the present invention, raw materials containing hydroxyalkyl groups, polyether groups, amino groups and sulfonic acid groups can be used to modify alkyl glycosides to obtain the modified alkyl glycoside products. Among them, the embodiment of the present invention provides the preparation method of the modified alkyl glycoside anti-high temperature strong inhibitor as described above, including the following steps:

[0044] S1, react after mixing the alkyl glycoside, halogenated epoxide and polymeric diol to obtain the halogenated alcohol polyether alkyl glycoside;

[0045] S2. Reacting the halohydrin polyether alkyl glycoside with an organic amine to obtain an amino polyether alkyl glycoside;

[0046] S3, reacting the amino polyether alkyl glycoside with sulfamic acid to obtain a modified alkyl glycoside with a strong inhibitor against high temperature.

[0047] In the embodiment of the present invention, the alkyl glucoside, the halogenated epoxide and the polymer...

Embodiment 1

[0058] Add 38g of epichlorohydrin, 80g of polyethylene glycol 200, 70g of methyl glucoside, and 4g of sulfuric acid into the reaction kettle, react at 95°C for 1.0h at a stirring speed of 800r / min, and lower to 40°C to obtain chlorohydrin polyether Methyl glucoside; slowly add 70g of ethylenediamine to the above reaction solution, keep the temperature at 85°C for 2.0h to obtain amino polyether methyl glycoside; add 24g of urea and 38g of sulfamic acid to the reaction solution, After reacting at ℃ for 0.5h, and cooling down to room temperature, a reddish-brown viscous modified methyl glycoside strong inhibitor against high temperature was obtained. The product yield is 85.66%.

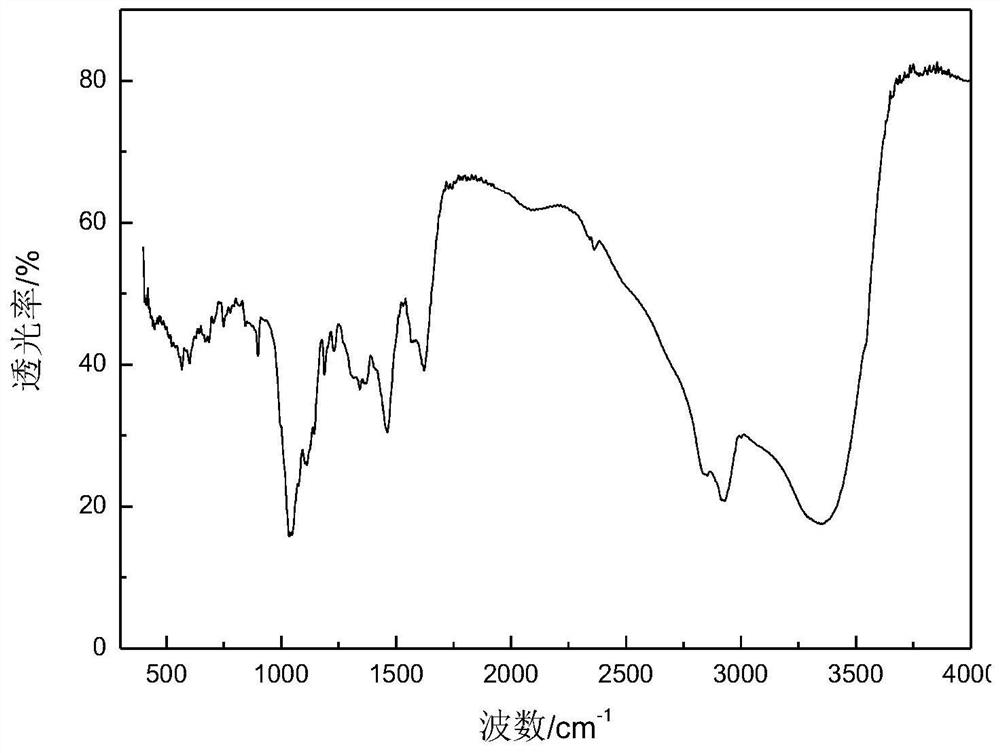

[0059] The modified methyl glucoside prepared in Example 1 of the present invention was carried out infrared detection, and the results were as follows: figure 1 shown. Among them, at 3380cm -1 It is the stretching vibration peak of O-H bond, 2830~2950cm -1 It is the stretching vibration peak of the...

Embodiment 2

[0062] Add 38g of epichlorobutane, 160g of polyethylene glycol 400, 80g of ethyl glucoside, and 5g of citric acid into the reaction kettle, and react at 100°C for 1.5h at a stirring speed of 900r / min, and then lower it to 40°C to obtain chlorohydrins Polyether ethyl glucoside; slowly add 80g of diethylenetriamine to the above reaction solution, keep the temperature at 90°C for 3.0h to obtain amino polyether ethyl glucoside; add 28g of ethyl urea, 42g of amino Sulfonic acid, react at 50°C for 1.0h, and cool down to room temperature to obtain reddish-brown viscous modified ethyl glycoside with high temperature resistance and strong inhibitor. The product yield is 86.58%.

[0063] The modified ethyl glucoside prepared in Example 2 of the present invention was subjected to infrared detection, and the results included: at 3381cm -1 It is the stretching vibration peak of O-H bond, 2831~2952cm -1 It is the stretching vibration peak of the C-H bond in the methyl group and the methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com