A kind of preparation method of density gradient fiber mat and fiber mat

A fiber mat and fiber technology, applied in the field of fiber mats, can solve the problems of poor elasticity and easy collapse of fiber mats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

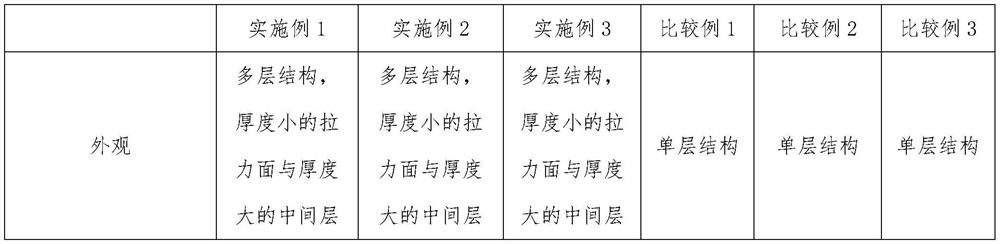

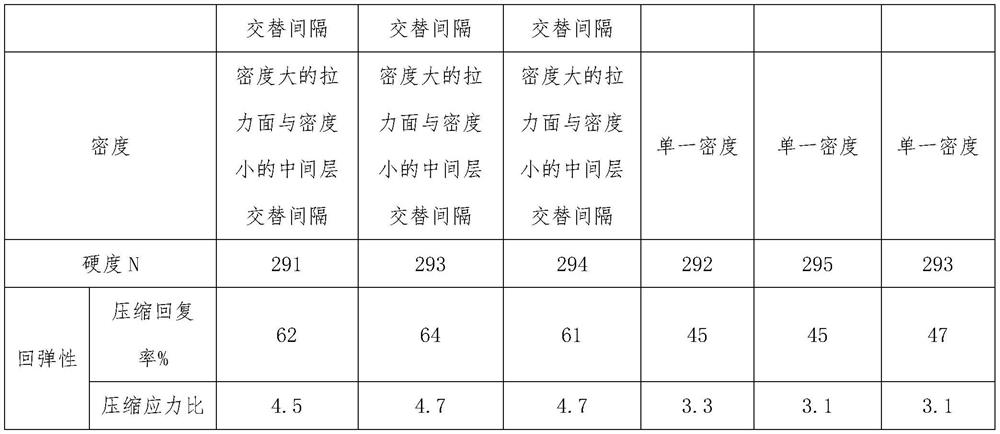

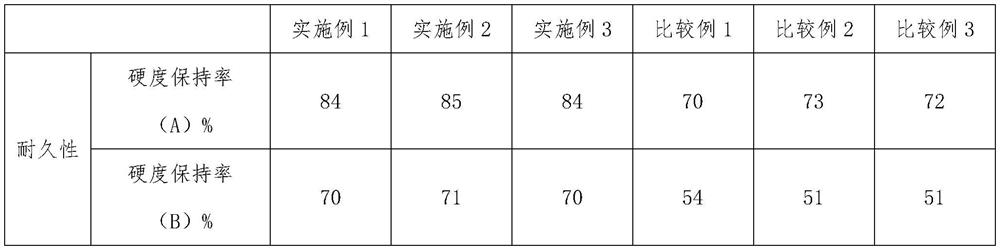

Examples

Embodiment 1

[0023] This embodiment provides a method for preparing a fiber mat, comprising the following steps:

[0024] Firstly, each fiber bundle in the raw material is opened by using a fiber opener to obtain raw material fibers after opening. The raw material fibers used are low-melting point hot-melt adhesive fibers and elastomer fibers, wherein the low-melting point hot-melt adhesive fibers are PET fibers with a melting point of about 130°C, and the elastomer fibers are three-dimensional crimped hollow fibers with a melting point of about 220°C. The content of the elastomer fiber was 60 wt%, and the content of the binder fiber was 40 wt%.

[0025] The second step is to mix the fiber raw materials, and use a fiber carding machine to card the loosened fibers to eliminate entanglement.

[0026] The third step is to use a web laying machine to spread the carded fibers evenly. After being carded into a uniform fiber web by a fiber carding machine, a continuous fiber network structure w...

Embodiment 2

[0032] The main method and steps of embodiment 2 are similar to embodiment 1, and the difference is that the used bonding fiber is a two-component sheath-core fiber with a melting point of about 140° C., and the elastomer fiber is an elk fiber (a) with a melting point of about 200° C. It is a kind of polyester cushioning fiber, which differs from ordinary fiber cushioning materials in that its fibers are arranged in a longitudinal structure). The content of the elastomer fiber was 65 wt%, and the content of the binder fiber was 35 wt%. The needling depth is 15mm, the speed is 7.5m / min, and the needling density is 480 pricks / cm 2 . During hot pressing, the heating temperature is 220° C., the wind speed is 30 m / s, and the fiber mat is pressed to a thickness of 6 cm.

Embodiment 3

[0034] The main method and steps of embodiment 3 are similar to embodiment 1, and the difference is that the used bonding fiber is the polyolefin fiber that fusing point is about 120 ℃, and the elastic body fiber is the polyether ester fiber (PP fiber) that fusing point is about 200 ℃. ). The content of the elastomer fiber was 70 wt%, and the content of the binder fiber was 30 wt%. The needling depth is 11mm, the speed is 6.0m / min, and the needling density is 320 pricks / cm 2 , the heat drying temperature is 140°C during the second hot pressing, the wind speed is 10m / s, and the fiber mat is pressed to a thickness of 10cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com