A kind of silicate-cationic alkyl glucoside drilling fluid and preparation method thereof

A technology of alkyl glucoside and alkyl glucoside, which is applied in the field of silicate-cationic alkyl glucoside drilling fluid and its preparation, can solve problems such as poor anti-slump performance and difficult control of rheology, and reduce water activity, Improve the efficiency of the semi-permeable membrane and meet the effect of wellbore stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: In 350ml of distilled water, with 8000-10000 rpm high-speed stirring, simultaneously add 0.35g xanthan gum, 3.5g low-viscosity sodium carboxymethylcellulose, 17.5g methyl glucoside, 3.5g Cationic methyl glucoside, after stirring at high speed for 10 minutes, add 3.5g of sulfonated lignite, 3.5g of calcium carbonate with a particle size range of 2.5-10 microns and 3.5g of cationic pitch, stir at high speed for 10 minutes, then add 35g of sodium silicate, 17.5g sodium chloride and 0.7g sodium hydroxide, after stirring at high speed for 20min, put it into the aging tank and get the density of 1.10g / cm without weight after 120℃ / 16h 3 Silicate-cationic alkyl glucoside drilling fluid.

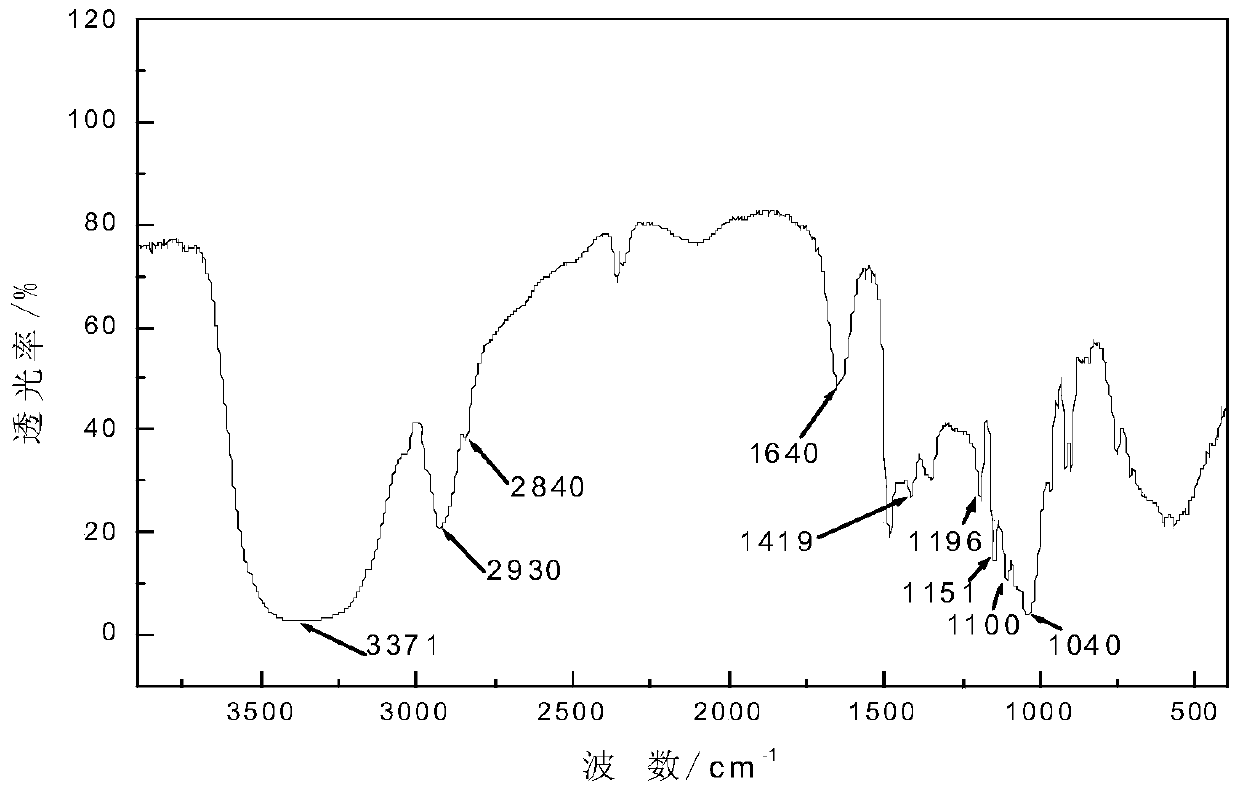

[0031] By carrying out the characterization analysis of infrared spectrum to the drilling fluid system of example 1, such as figure 1 Shown: 1151cm -1 It is the stretching vibration peak of C-O-C, and it is determined to contain glucoside structure; 1419cm -1 It is the absorption...

Embodiment 2

[0032] Example 2: In 350ml of distilled water, with 8000-10000 rpm high-speed stirring, add 0.70g xanthan gum, 0.35g high viscosity sodium carboxymethyl cellulose, 5.25g low viscosity sodium carboxymethyl fiber at the same time element, 1.75g zwitterionic sulfonate polymer, 17.5g methyl glucoside, 3.5g cationic methyl glucoside, after stirring at high speed for 15min, add 3.5g sulfonated lignite, 3.5g sulfonated phenolic resin-II, 3.5 g calcium carbonate with a particle size range of 2.5-10 microns, 3.5g emulsified asphalt, 10.5g potassium humate, 3.5g nanmu powder, after stirring at high speed for 20min, add 24.5g sodium silicate, 52.5g sodium chloride and 1.0g After stirring sodium hydroxide at high speed for 10 minutes, add 56g of barite and stir at high speed for 30 minutes, put it into an aging tank and put it into an aging tank at 120°C / 16h to obtain a density of 1.20g / cm 3 Silicate-cationic alkyl glucoside drilling fluid.

Embodiment 3

[0034] Example 3: In 350ml of distilled water, under the condition of high-speed stirring at 8000-10000 rpm, add 0.35g xanthan gum, 0.35g potassium polyacrylate, 7.0g low-viscosity sodium carboxymethylcellulose, 1.75g amphoteric Ionic sulfonate polymer, 21g ethyl glucoside, 5.25g cationic methyl glucoside, after stirring at high speed for 20min, add 7.0g sulfonated lignite, 3.5g calcium carbonate with a particle size range of 2.5-10 microns and 3.5g emulsified Asphalt, 10.5g potassium humate, 3.5g Phoebe powder, after high speed stirring for 15min, then add 17.5g sodium silicate, 17.5g potassium chloride, 35g sodium chloride, 0.7g sodium hydroxide, after high speed stirring for 10min, then Add 56g of barite and stir at high speed for 30min, put it into the aging tank and get a density of 1.20g / cm after 120℃ / 16h 3 Silicate-cationic alkyl glucoside drilling fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com