Cathode material for long-circulation lithium-sulfur battery and preparation method thereof

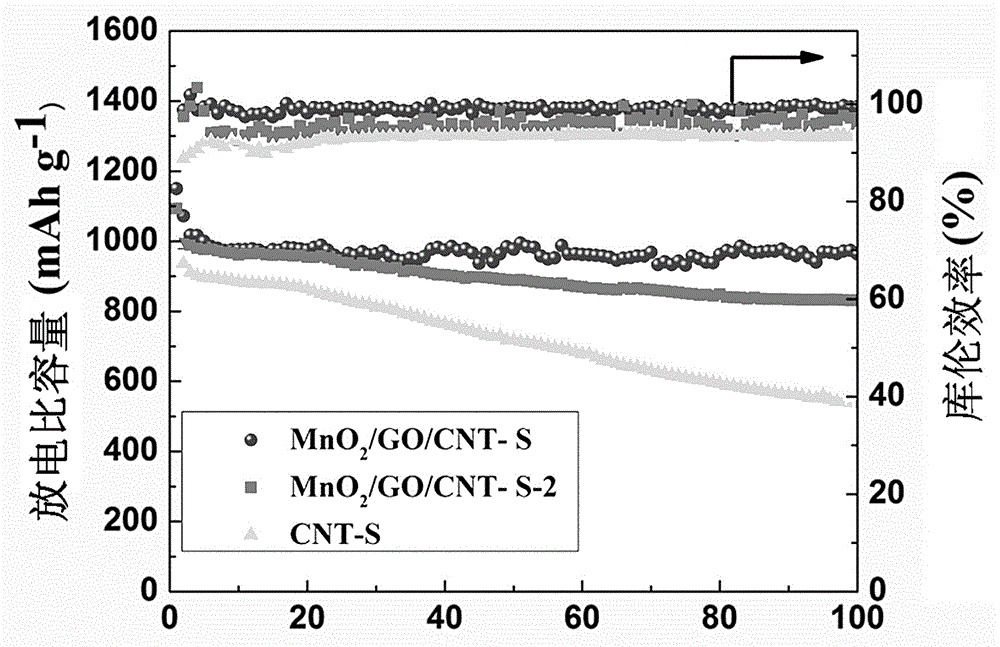

A cathode material, lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, nanotechnology for materials and surface science, etc., can solve the problems of low conductivity and affect the electrode rate performance, etc. Coulombic efficiency and cycle performance, the effect of improving electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

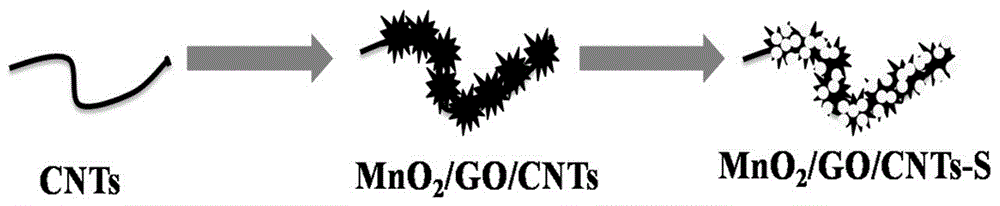

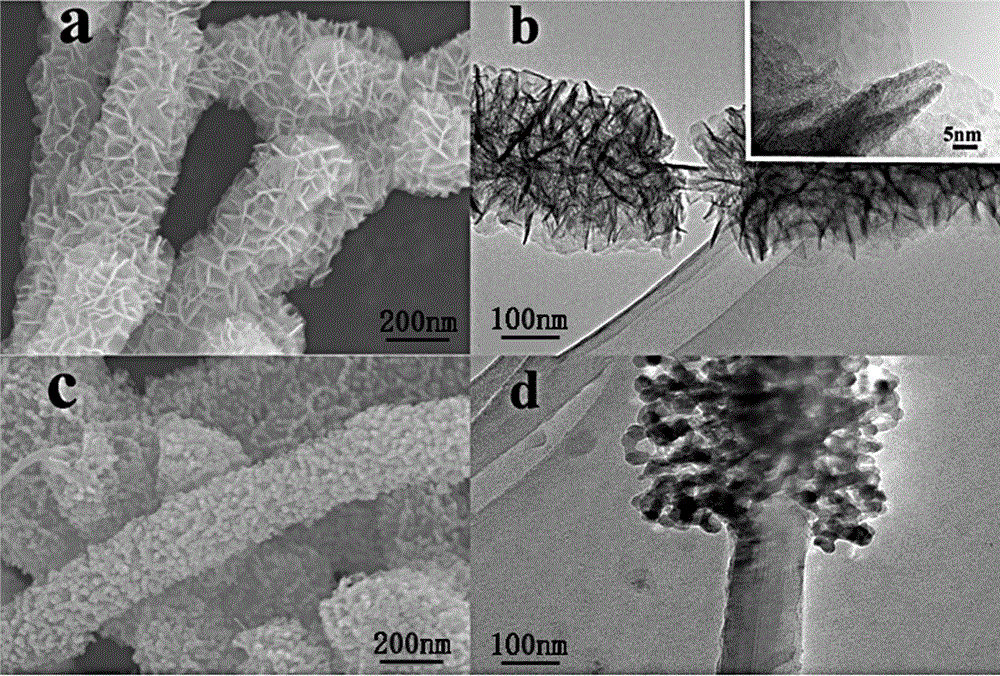

[0055] The first preparation method (melt composite method) of a composite material of sulfur / manganese dioxide / graphene oxide / carbon nanotubes with a three-dimensional structure.

[0056] Step 1: Take 1g of carbon nanotubes and disperse them in a concentrated acid solution (volume ratio of concentrated nitric acid to concentrated sulfuric acid is 1:3). ), after ultrasonic dispersion for 10 min, change to magnetic stirring at room temperature for 1 h, raise the temperature to 70 ° C, and stir for 4 h to carry out nano-exfoliation of the surface of carbon nanotubes. This step can be used to remove impurities in carbon nanotubes and graft oxygen-containing chemical functional groups;

[0057] Step 2: Lower the temperature of the above solution to 0°C, add 5mL of concentrated sulfuric acid and continue to stir for 30min, then raise the temperature to 55°C, add 3g of potassium permanganate, continue to stir for 120min, raise the temperature to 90°C and stir for 10min, and finally ...

Embodiment 2

[0060] The second preparation method (solvent exchange method) of sulfur / manganese dioxide / graphene oxide / carbon nanotube composites with three-dimensional structure.

[0061] The first step and second step are identical with embodiment 1;

[0062] The third step: take 1g of the composite material of the above-mentioned manganese dioxide / graphene oxide / carbon nanotubes, disperse it in the carbon disulfide solution, add 3g of sulfur powder to the above-mentioned dispersion, and stir it in a closed manner for 2h, then place it in a fume hood Stir at 50°C until carbon disulfide is completely volatilized to obtain a three-dimensional structure of sulfur / manganese dioxide / graphene oxide / carbon nanotube composite (MnO 2 / GO / CNTs-S).

Embodiment 3

[0064] The third preparation method (in situ solution precipitation method) of sulfur / manganese dioxide / graphene oxide / carbon nanotube composites with three-dimensional structure.

[0065] The first step and second step are identical with embodiment 1;

[0066] Step 3: Take 1 g of the above manganese dioxide / graphene oxide / carbon nanotube composite material, disperse it in 200 mL of deionized water, ultrasonicate for 30 min, add 100 mL of 1 mol / L sodium polysulfide solution to the solution, and continue stirring for 1 h, Then add 200mL of 1mol / L hydrochloric acid dropwise to the above-mentioned dispersion liquid, filter and dry to obtain the composite material (MnO 2 / GO / CNTs-S).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com