Lithium anode with inorganic protective coating and preparation method thereof

A technology of inorganic protection and lithium negative electrode, applied in the field of lithium negative electrode and its preparation, lithium negative electrode with inorganic protective coating and its preparation, to achieve the effect of simple operation, improved cycle performance and inhibited growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

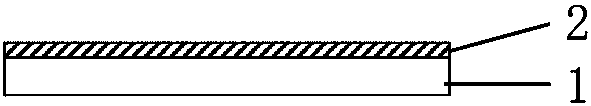

Image

Examples

Embodiment 1

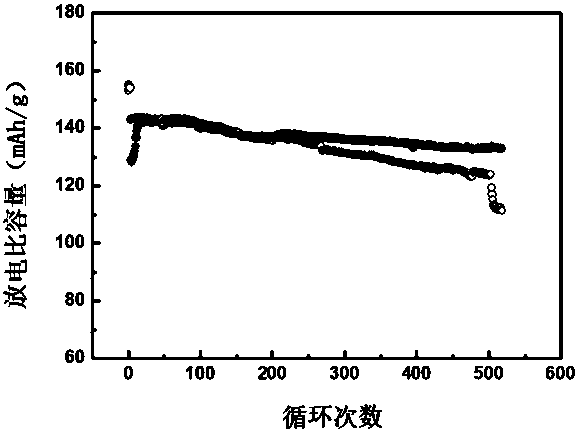

[0030] Mix nickel fluoride powder with a particle size of 50nm and polyvinylidene fluoride binder at a mass ratio of 7:3, add an appropriate amount of N-methylpyrrolidone to adjust the paste viscosity, and stir thoroughly for 12 hours. The uniformly mixed slurry was uniformly dropped on the lithium sheet, and dried in vacuum at 60° C. for 10 h to obtain an inorganic protective coating with a thickness of 500 nm. The prepared lithium flakes were mixed with lithium iron phosphate positive electrode and carbonate-based electrolyte (the solute was 1M LiPF 6 , the solvent is EC:DMC:DEC with a volume ratio of 1:1:1) the battery was assembled in an argon-filled glove box (water, oxygen content ≤ 1ppm), and the performance of the battery was tested after standing for 12 hours. The charging and discharging voltage ranges from 2.5V to 4.2V, and it is activated at 0.1C (1C=170mAh / g) for 3 times and then cycled at 1C. Such as figure 2 As shown, after 500 cycles, the specific capacity i...

Embodiment 2

[0032] Mix tin fluoride powder with a particle size of 60nm and polyvinylidene fluoride binder at a mass ratio of 7:3, add an appropriate amount of N-methylpyrrolidone to adjust the paste viscosity, and stir thoroughly for 12 hours. The uniformly mixed slurry was uniformly dropped on the lithium sheet, and dried in vacuum at 60° C. for 10 h to obtain an inorganic protective coating with a thickness of 500 nm. The prepared lithium flakes were mixed with lithium iron phosphate positive electrode and carbonate-based electrolyte (the solute was 1M LiPF 6 , the solvent is EC:DMC:DEC with a volume ratio of 1:1:1) the battery was assembled in an argon-filled glove box (water, oxygen content ≤ 1ppm), and the performance of the battery was tested after being left for 12 hours. The charging and discharging voltage ranges from 2.5V to 4.2V, and it is activated at 0.1C (1C=170mAh / g) for 3 times and then cycled at 1C. After 500 cycles, the specific capacity is 134.2 mAh / g, and the capacit...

Embodiment 3

[0034] Mix aluminum fluoride powder with a particle size of 50nm and polyvinylidene fluoride binder at a mass ratio of 7:3, add an appropriate amount of N-methylpyrrolidone to adjust the paste viscosity, and stir thoroughly for 12 hours. The uniformly mixed slurry was uniformly dropped on the lithium sheet, and dried in vacuum at 60° C. for 10 h to obtain an inorganic protective coating with a thickness of 300 nm. The prepared lithium flakes were mixed with lithium iron phosphate positive electrode and carbonate-based electrolyte (the solute was 1M LiPF 6 , the solvent is EC:DMC:DEC with a volume ratio of 1:1:1) the battery was assembled in an argon-filled glove box (water, oxygen content ≤ 1ppm), and the performance of the battery was tested after being left for 12 hours. The charging and discharging voltage ranges from 2.5V to 4.2V, and it is activated at 0.1C (1C=170mAh / g) for 3 times and then cycled at 1C. After 500 cycles, the specific capacity is 133.6 mAh / g, and the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com