Lithium metal negative electrode for secondary battery, preparation method and application of lithium metal negative electrode

A secondary battery and metal lithium technology, which is applied in secondary batteries, electrode manufacturing, battery electrodes, etc., can solve problems such as poor stability, and achieve the effects of preventing clogging, high specific surface characteristics, and preventing lithium dendrite growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

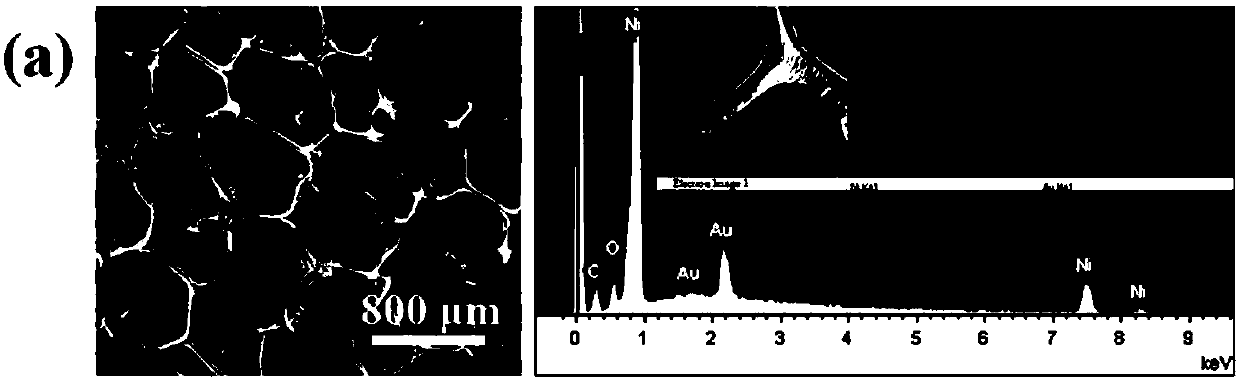

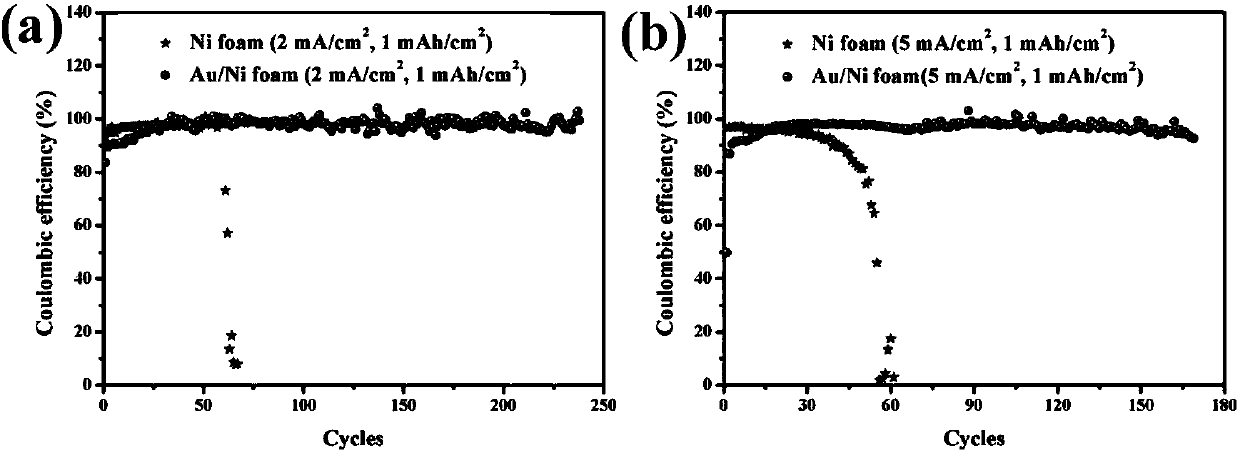

[0040] Sputter a layer of nano-Au particles on the bottom (any plane) of the nickel foam current collector (Ni foam) as a lithium deposition induction layer by ion sputtering method (using a gold plate as a target, sputtering for 200s at a current of 20mA) , the thickness of the nano-Au particle layer is about 10nm. A porous lithium anode (Au / Ni foam) was fabricated by depositing Li in Au-modified porous nickel by electrodeposition in a glove box. The SEM image of the prepared porous lithium anode is shown in figure 1 Part (a) of ; EDS diagram see figure 1 Part (b) of.

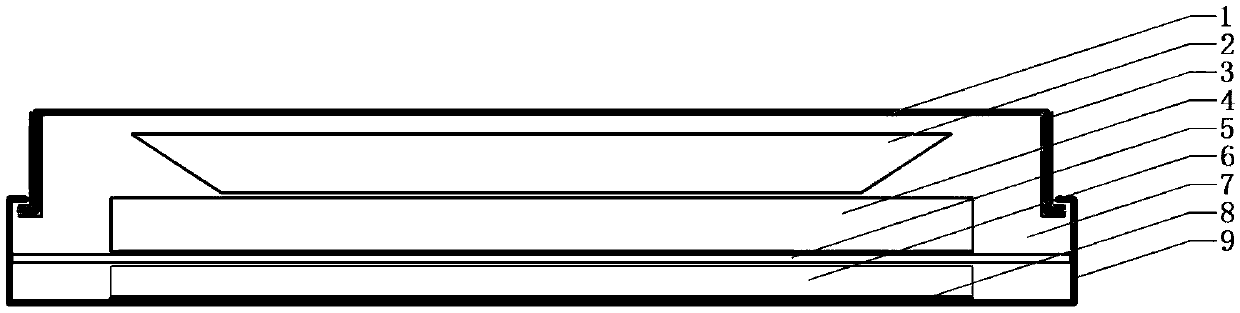

[0041] With metal lithium sheet as positive electrode, 1M LiTFSI / DOL:DME (volume ratio=1:1) contains 1%wtLiNO 3 Be electrolytic solution, be assembled into 2032 button-type lithium-ion batteries with the lithium negative pole that the present invention makes (according to figure 2 Assembled in the same way, that is, the surface sputtered with Au particles is set at the far end of the separator), the separ...

Embodiment 2

[0045] A layer of nano-ZnO particles was grown on the bottom of the carbon paper (CP) current collector as a lithium deposition induction layer by magnetron sputtering (using a zinc oxide plate as a target, sputtering for 15 s at a sputtering power of 80W), and nano-ZnO The thickness of the layer is 5 nm. A 2025 button lithium-ion battery was assembled in a glove box with Celgard 2400 as a separator, and Li was deposited in a ZnO-modified carbon paper current collector by electrodeposition to prepare a porous ZnO / C lithium anode. The carbon paper lithium anode with the same structure and no lithium deposition induction layer was coated as a comparison sample (morphology and energy spectrum see Figure 5 ). Test finds, adopt the present invention to have the ZnO / C lithium negative pole of lithium deposition lure layer in 1mA / cm 2 The cycle life under charge and discharge current density is 5 times that of ordinary carbon paper lithium anode ( Image 6 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com