Continuous lithium powder replenishing method for both sides of lithium ion battery negative plate

A technology of lithium ion battery and negative electrode sheet, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of lithium supplementation of negative electrode sheets, harsh environmental requirements, uneven lithium insertion, etc., to suppress the production of HF acid and improve the first time Efficiency, protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

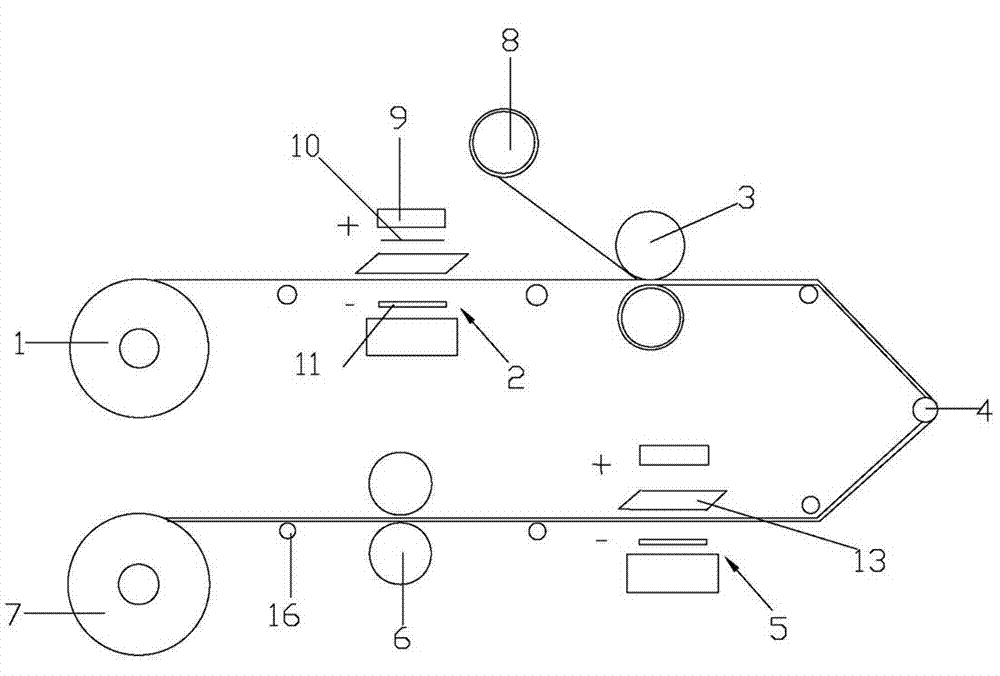

[0029] Such as figure 1As shown, the device used in the present invention includes an unwinding mechanism 1, a first lithium replenishment system 2, a protective film system 8 for preventing the adhesion between the layers of the negative electrode sheet 12 after the lithium powder is rolled, and The first rolling system 3, the tension adjustment turning mechanism 4 for adjusting the tension and turning over the lithium filling surface of the negative electrode sheet 12, the second lithium filling system 5, the second rolling system 6 and the winding mechanism 7, the first Both the lithium supplement system 2 and the second lithium supplement system 5 include a feeding system 9 for placing lithium powder and sprinkling powder, a screen electrode 10 and a transfer electrode 11, and the screen electrode 10 and the transfer electrode 11 are respectively located on the negative plate 12 above and below, and the screen electrode 10 and the transfer electrode 11 are respectively ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com