Silicon-carbon composite electrode and preparation method thereof

A silicon-carbon composite and electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as rate performance affecting material cycle performance, poor bonding force between silicon and carbon materials, poor consistency, etc., to improve the first efficiency and process. The effect of controllable and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

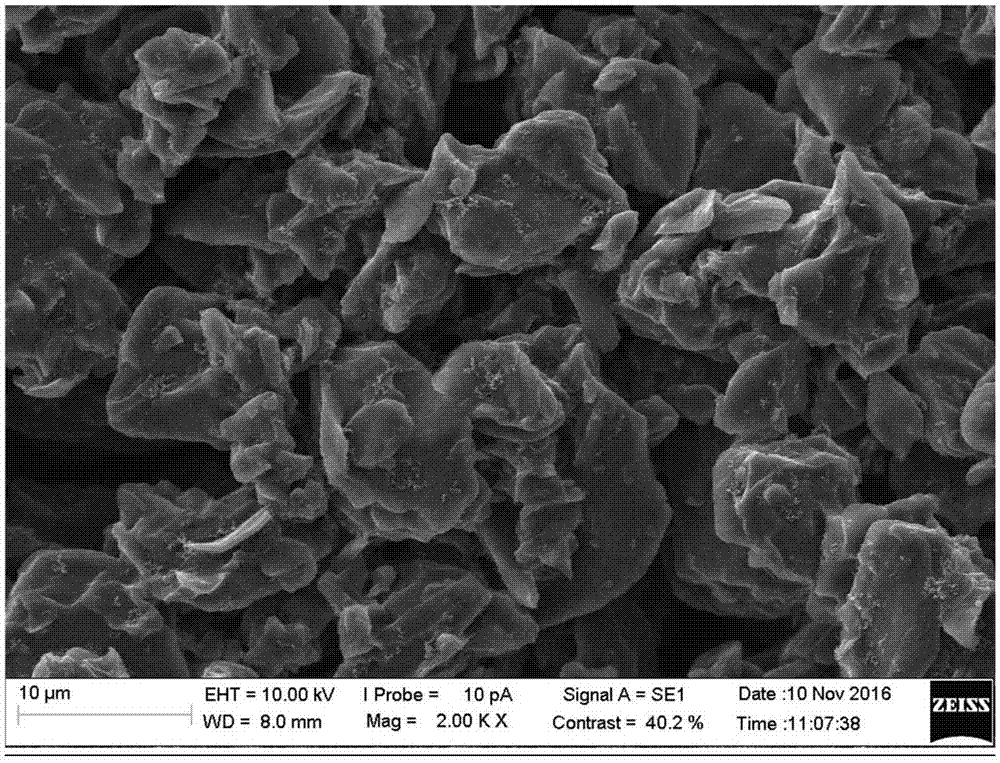

[0022] A silicon-carbon composite electrode has a core-shell structure, in which the inner core includes silicon powder and hollow carbon spheres doped in the silicon powder, and an inorganic lithium salt compound electrodeposited between the silicon powder and the hollow carbon spheres, and the outer shell is a polymer polymer.

[0023] Optimally, the inorganic lithium salt compound is one of lithium carbonate, lithium hydroxide, lithium metaaluminate, and lithium borate, and lithium carbonate is preferred in this embodiment.

[0024] Optimally, the silicon powder is 50-500nm nano-silicon, and the silicon powder can be 50nm nano-silicon, 200nm nano-silicon or 500nm nano-silicon, etc. In this embodiment, it is preferably 50nm nano-silicon.

Embodiment 2

[0026] 1) In an environment with a dew point ≤ -30°C, weigh 10g of silicon powder with a particle size of 100nm, 10g of sodium dodecylbenzenesulfonate, and 10g of hollow carbon spheres and add them to 500ml of toluene solvent for reaction, dry and pulverize to obtain a precursor Body, then mixed with 1g of polyvinylidene fluoride binder and pressed onto the nickel foam to obtain electrode A;

[0027] 2) Add 2g of lithium carbonate to 100ml of ethylene carbonate to dissolve, stir evenly to obtain a solvent, then use electrode A as the working electrode, platinum sheet as the counter electrode, and use cyclic voltammetry (voltage range -3V ~ 3V, scan speed 2mV / S, scanning for 10 weeks), deposit lithium salt on the surface of the working electrode, then take it out and clean it with pure ethylene carbonate, and dry it to obtain a lithium-silicon composite electrode;

[0028] 3) Add 20 g of lithium-supplemented silicon composite electrode to 150 ml of polypropylene carbonate solve...

Embodiment 3

[0030] 1) In an environment with a dew point ≤ -30°C, weigh 5g of silicon powder with a particle size of 50nm, 5g of sodium dodecylbenzenesulfonate, and 5g of hollow carbon spheres and add them to 500ml of carbon tetrachloride solvent for reaction, dry and pulverize Finally, the precursor is obtained, and then mixed with 0.5g of polyvinylidene fluoride binder and pressed onto the nickel foam to obtain electrode A;

[0031] 2) Afterwards, add 0.5g lithium hydroxide to 100ml ethylene carbonate to dissolve and stir evenly to obtain a solvent, then use electrode A as the working electrode, platinum sheet as the counter electrode, and use cyclic voltammetry (voltage range -3V-3V , scanning speed is 0.5mV / s, scanning 10 weeks), lithium salt is deposited on the surface of the working electrode, then taken out and cleaned with pure ethylene carbonate, dried to obtain lithium-silicon composite material;

[0032] 3) Afterwards, 5 g of the lithium-supplementing silicon composite material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com