Preparation method of high-nickel ternary material

A technology of high-nickel ternary materials and intermediates, applied in electrode manufacturing, electrical components, electrode heat treatment, etc., can solve the problems of intensified Li ion diffusion, low initial efficiency and power, and poor material reversibility, and achieve crystallinity High, high first-time efficiency, and crystallinity-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

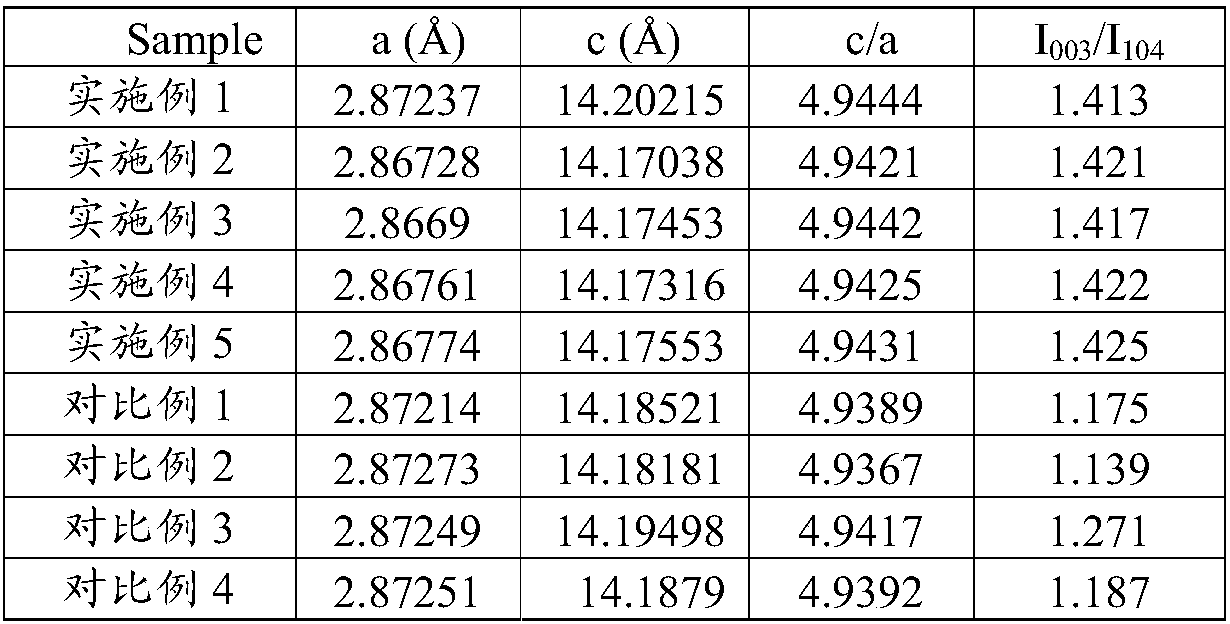

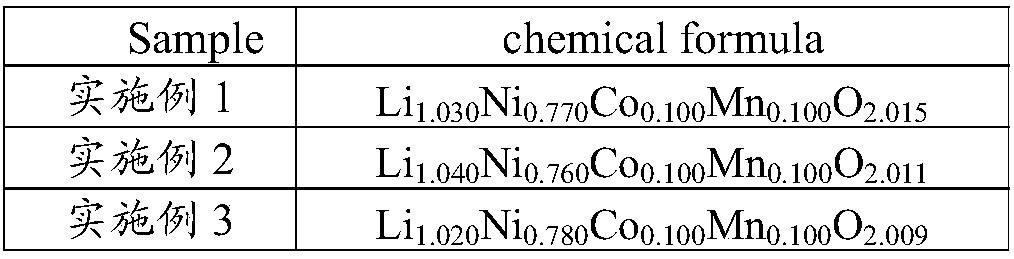

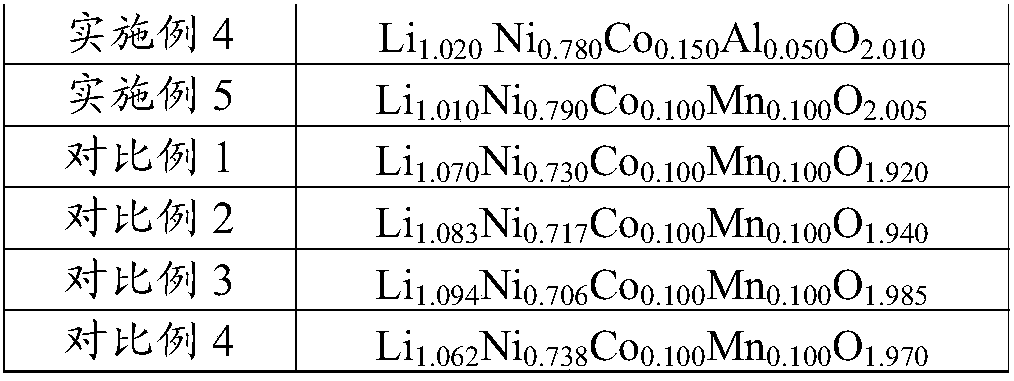

[0010] The application provides a method for preparing a high-nickel ternary material, the high-nickel ternary material is Li (1+a) Ni x co y m z o 2+b , where, -0.10≤a≤0.50, 0.8≤x<0.9, 0.1≤y≤0.25, 0

[0011] Further, the sintering in the first stage is as follows: the mixture added with the sintering aid is heated up to 650-750°C at a heating rate of 0.5-10°C / min in an air atmosphere, and kept for 3-6h to obtain intermediate I. The first temperature platform is set at a pos...

Embodiment 1

[0029] High nickel ternary material Li 1.01 Ni 0.8 co 0.1 mn 0.1 o 2.005 The preparation method is:

[0030] a. Precursor preparation

[0031] Add metal Ni, Co, Mn sulfate solution, morphology control agent ammonia water, and NaOH solution into the reaction kettle and mix them in parallel, control the pH = 12, and react at a constant temperature at 65 ° C, and continuously react until the particle size D50 is 10um, the precursor Ni was obtained after filtration and washing 0.8 co 0.1 mn 0.1 (OH) 2 ;

[0032] b. mix

[0033] Mix the precursor and lithium hydroxide at a molar ratio of 1:1.10, add boron oxide, a water-insoluble additive accounting for 10% of the mass of the precursor, and mix evenly;

[0034] c. Three-stage sintering

[0035] Carry out the first-stage sintering of the mixed mixture in b: put it in an air atmosphere, raise the temperature to 650°C at a heating rate of 1°C / min, and keep it for 4h to obtain intermediate I;

[0036] Then carry out the se...

Embodiment 2

[0039] High nickel ternary material Li 1.01 Ni 0.8 co 0.1 mn 0.1 o 2.005 The preparation method is:

[0040] a. Precursor preparation

[0041] Add the sulfate solution of metal Ni, Co, Mn, shape control agent ammonia, and sodium carbonate solution in the reaction kettle to carry out parallel flow mixing in the reaction kettle, control the pH=12, and react at a constant temperature at 65°C, and continue the reaction until The particle size D50 is 9um, and the precursor Ni is obtained after filtering and washing 0.8 co 0.1 mn 0.1 CO 3 ;

[0042] b. mix

[0043] Mix the precursor and lithium hydroxide at a molar ratio of 1:1.10, add boron oxide, a water-insoluble additive accounting for 10% of the mass of the precursor, and mix evenly;

[0044] c. Three-stage sintering

[0045] Carry out the first-stage sintering of the mixed mixture in b: put it in an air atmosphere, raise the temperature to 650°C at a heating rate of 1°C / min, and keep it for 4h to obtain intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com