Lithium ion battery composite diaphragm, preparation method thereof and lithium ion battery

A technology of lithium-ion batteries and composite diaphragms, applied in secondary batteries, battery components, circuits, etc., can solve problems such as poor stability and poor safety performance, and achieve the goal of improving uniformity, improving safety performance, and reducing irreversible capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

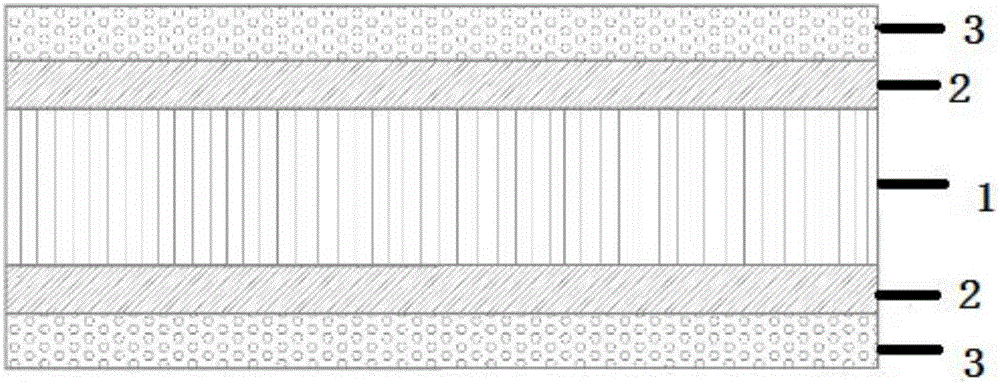

[0044] The lithium-ion battery composite diaphragm of the present embodiment includes a diaphragm substrate 1, the diaphragm substrate includes a polyolefin microporous membrane and ceramic layers 2 coated on both surfaces of the polyolefin microporous membrane, and the surfaces of the two ceramic layers are coated with Lithium supplementation layer 3; the ceramic layer is composed of 15 parts by weight of aluminum oxide powder, 15 parts by weight of lithium metaaluminate powder and 3 parts by weight of polyvinylidene fluoride uniformly mixed and bonded together; the lithium supplementation layer It consists of 3 parts by weight of lithium powder, 3 parts by weight of graphene, 15 parts by weight of polypropylene carbonate, and 15 parts by weight of composite polyethylene uniformly mixed and bonded together, wherein the particle size of lithium powder is 0.1mm, composite polyethylene is composed of high-density polyethylene with a weight-average molecular weight of 100,000 and ...

Embodiment 2

[0051] The lithium-ion battery composite diaphragm of this embodiment includes a diaphragm base, and the diaphragm base includes a polyolefin microporous membrane and ceramic layers coated on both surfaces of the polyolefin microporous membrane, and the surfaces of the two ceramic layers are coated with lithium-supplementing layer; the ceramic layer is composed of 10 parts by weight of aluminum oxide powder, 10 parts by weight of lithium metaaluminate powder and 1 part by weight of polyvinylidene fluoride uniformly mixed and bonded together; the lithium supplement layer consists of 1 weight part 1 part by weight of lithium powder, 1 part by weight of graphene, 10 parts by weight of polypropylene carbonate, and 10 parts by weight of composite polyethylene are uniformly mixed and bonded together to form, wherein the particle diameter of lithium powder is 0.075mm, Composite polyethylene is composed of high-density polyethylene with a weight-average molecular weight of 300,000 and ...

Embodiment 3

[0058] The lithium-ion battery composite diaphragm of this embodiment includes a diaphragm base, and the diaphragm base includes a polyolefin microporous membrane and ceramic layers coated on both surfaces of the polyolefin microporous membrane, and the surfaces of the two ceramic layers are coated with lithium-supplementing layer; the ceramic layer is composed of 20 parts by weight of aluminum oxide powder, 18 parts by weight of lithium metaaluminate powder and 5 parts by weight of polyvinylidene fluoride uniformly mixed and bonded together; the lithium supplementary layer is composed of 5 parts by weight The lithium powder of 5 parts by weight, the graphene of 5 parts by weight, the polypropylene carbonate of 20 parts by weight, the composite polyethylene of 20 parts by weight are uniformly mixed and bonded together to form, wherein, the particle diameter of lithium powder is 0.15mm, Composite polyethylene is composed of high-density polyethylene with a weight-average molecul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com