Preparation method of lithium ion battery silicon-carbon anode material

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low material production efficiency, unfavorable industrialized production, low first coulomb efficiency, etc., and achieve sufficient supply and low equipment cost. , the effect of improving the first efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

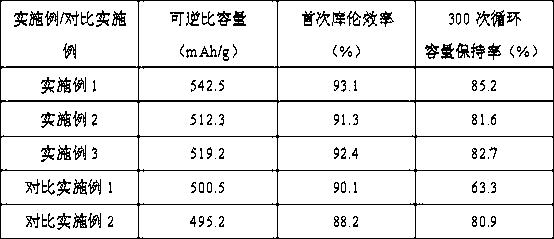

Examples

Embodiment 1

[0028] Example 1 of the present invention provides a method for preparing a silicon-carbon negative electrode material for a lithium-ion battery, including the following steps.

[0029] (1) Add D50=5μm polysilicon and zirconia balls into the zirconia ball milling tank at a mass ratio of 1:3, turn forward at 300 rpm for 30 minutes and then let it stand for 5 minutes. After standing, turn it forward at 300 rpm Reverse the minutes for 30 minutes, continue to stand still for 5 minutes, and then continue to rotate forward, so reciprocating, to meet the total ball milling time of 12h. After the ball milling is completed, zirconia balls and silicon powder are separated through a sieve to obtain nano-sized silicon powder.

[0030] (2) Add the nano-scale silicon powder obtained in step (1) and the conductive agent Super-P into the zirconia ball milling tank at a mass ratio of 10:2, and continue to add the Zirconium balls, the uniform powder of nano silicon powder and Super-P can be ob...

Embodiment 2

[0036] Example 2 of the present invention provides a method for preparing a silicon-carbon negative electrode material for a lithium-ion battery, including the following steps.

[0037] (1) Add D50=5μm polysilicon and zirconia balls into the zirconia ball milling tank at a mass ratio of 1:3, rotate forward at 200 rpm for 30 minutes and then stand for 5 minutes. After standing, turn at 200 rpm Reverse the minutes for 30 minutes, continue to stand still for 5 minutes, and then continue to rotate forward, so reciprocating, to meet the total ball milling time of 14h. After the ball milling is completed, zirconia balls and silicon powder are separated through a sieve to obtain nano-sized silicon powder.

[0038] (2) Add the nano-scale silicon powder obtained in step (1) and the conductive agent Super-P into the zirconia ball mill tank according to the mass ratio of 10:1, and continue to add the oxidized powder at the mass ratio of material: zirconia ball = 1:3 Zirconium balls, the...

Embodiment 3

[0044] Example 3 of the present invention provides a method for preparing a silicon-carbon negative electrode material for a lithium-ion battery, including the following steps.

[0045] (1) Add D50=5μm polysilicon and zirconia balls into the zirconia ball milling tank at a mass ratio of 1:3, turn forward at 400 rpm for 30 minutes and then let it stand for 5 minutes. After standing, turn it forward at 400 rpm Reverse the minutes for 30 minutes, continue to stand still for 5 minutes, and then continue to rotate forward, so reciprocating, to meet the total ball milling time of 16h. After the ball milling is completed, zirconia balls and silicon powder are separated through a sieve to obtain nano-sized silicon powder.

[0046] (2) Add the nano-scale silicon powder obtained in step (1) and conductive graphite as a conductive agent into the zirconia ball mill tank at a mass ratio of 10:3, and continue to add zirconia at a mass ratio of material: zirconia balls = 1:3 Balls, after ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com